Crossed rotation type radial contraction and expansion tubular fabric as well as preparation method and purpose thereof

A technology of rotating and tubular fabrics, which is applied in the direction of braids, textiles, and papermaking, and can solve the problems of cross-rotating radial shrinkage and expansion tubular fabrics and tubular fabrics that do not involve radial shrinkage and expansion functions. Effects of smoothness of withdrawal, high smoothness of withdrawal, and low tensile elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

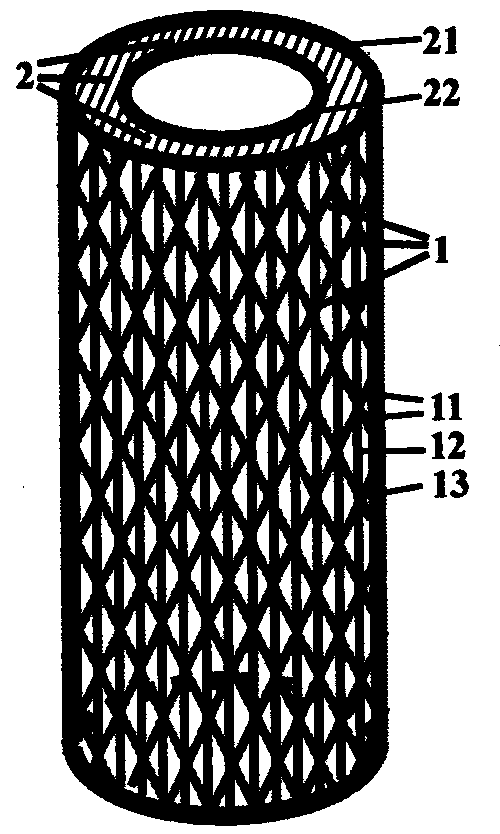

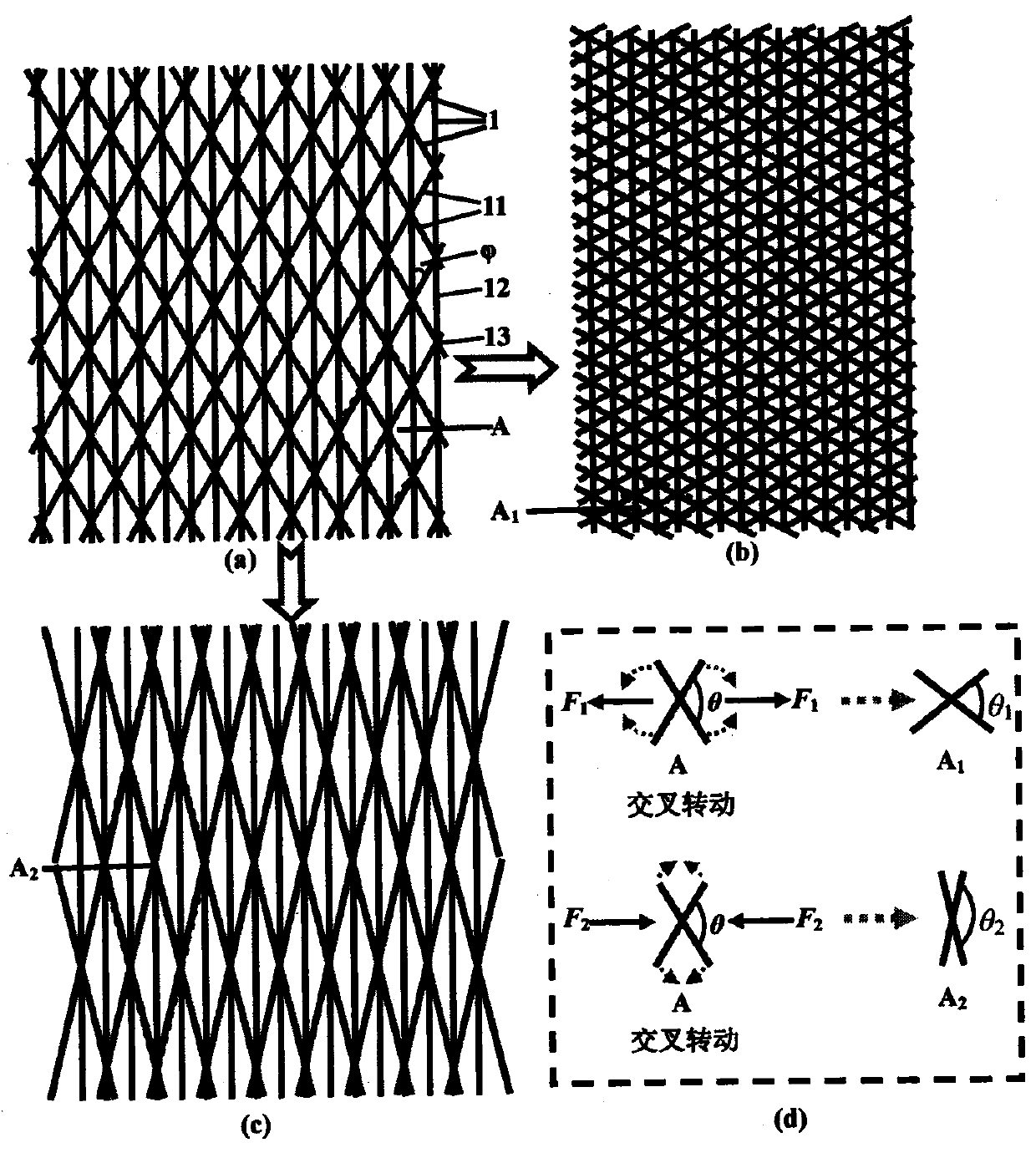

[0037] like figure 1 As shown, a cross-rotating radially expandable tubular fabric is a radially expandable tubular fabric 1 woven without weft yarns formed by weaving with symmetrical intersecting threads 11 and stabilizing warp yarns 12 .

[0038] When the tubular fabric 1 is braided and formed, the value of the crossing angle θ between the two crossing lines 11 is 90°; The relationship is: So helix angle is 45°.

[0039] The warp yarn 12 of the tubular fabric 1 adopts linear elastic weakly twisted Kevlar filament yarn with a modulus of 763.15cN / dtex, and the elongation at break is not more than 7%. Silk.

[0040] like figure 2 As shown, the tubular fabric 1 is characterized by:

[0041] ①The elastic elongation of the warp yarn 12 is not more than 10%, so as to ensure that the maximum elongation of the tubular fabric 1 in the axial direction is not more than 10%;

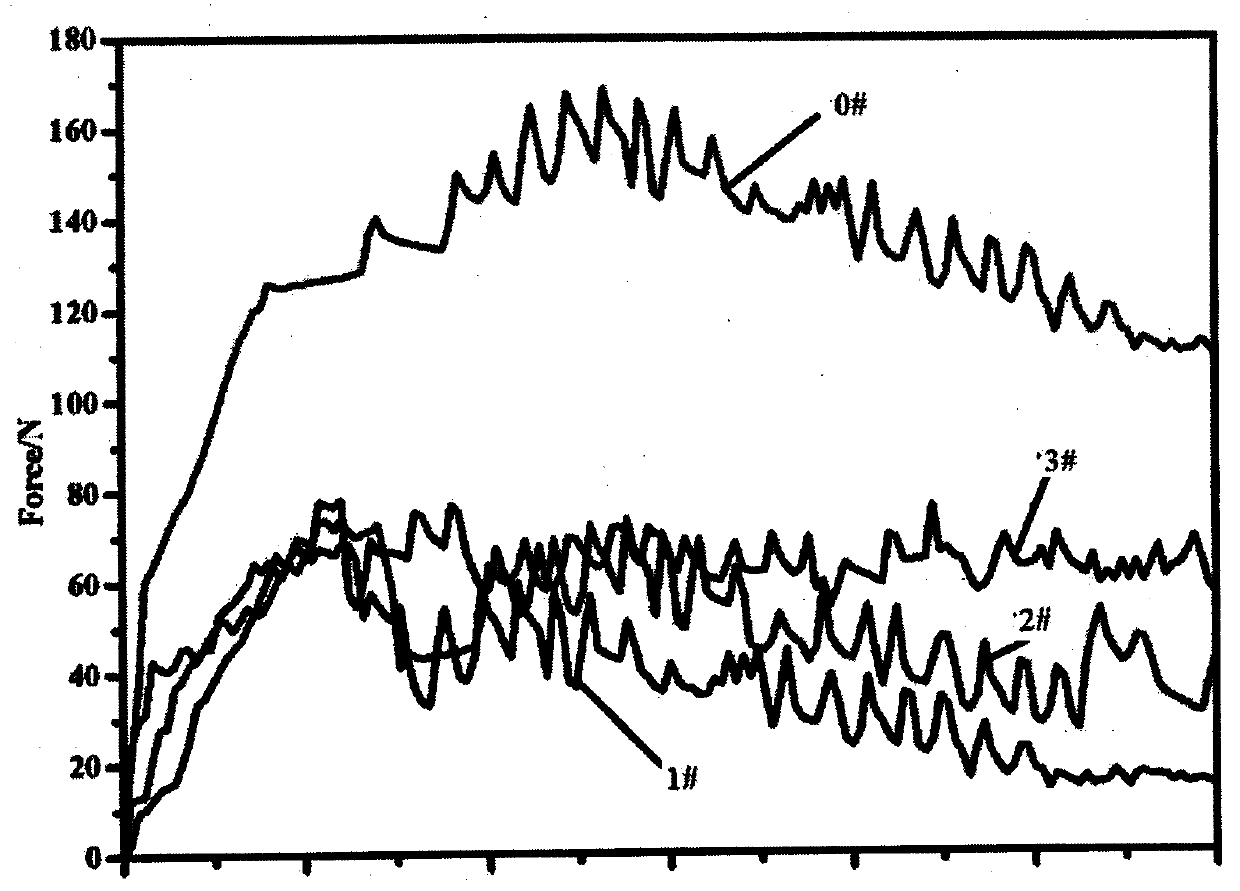

[0042] ② When the tubular fabric 1 is coated on the outer wall of the round tube, when the pulling m...

Embodiment 2

[0049] like figure 1 As shown, a cross-rotating radially expandable tubular fabric is a radially expandable tubular fabric 1 woven without weft yarns formed by weaving with symmetrical intersecting threads 11 and stabilizing warp yarns 12 .

[0050] The tubular fabric 1 is woven with symmetrical intersecting threads 11 to stabilize the warp yarns 12, thereby forming a radially expandable tubular structural fabric.

[0051] When the tubular fabric 1 is braided and formed, the value of the crossing angle θ between the two crossing lines 11 is 100°; The relationship is: So helix angle is 40°.

[0052] The warp yarn 12 of the tubular fabric 1 is made of linear elastic weakly twisted Kevlar filament with a modulus of 763.15cN / dtex, and the elongation at break is not more than 7%; the crossing thread 11 is made of rigid untwisted PBO filament with a smooth surface friction coefficient of 0.17.

[0053] like figure 2 As shown, the tubular fabric 1 is characterized by:

[00...

Embodiment 3

[0062] like figure 1 As shown, a cross-rotating radially expandable tubular fabric is a radially expandable tubular fabric 1 woven without weft yarns formed by weaving with symmetrical intersecting threads 11 and stabilizing warp yarns 12 .

[0063] The tubular fabric 1 is woven with symmetrical intersecting threads 11 to stabilize the warp yarns 12, thereby forming a radially expandable tubular structural fabric.

[0064] When the tubular fabric 1 is braided and formed, the value of the crossing angle θ between the two crossing lines 11 is 120°; The relationship is: So helix angle is 30°.

[0065] The warp yarn 12 of the tubular fabric 1 adopts linear elastic weakly twisted Kevlar filaments with a modulus of 763.15cN / dtex, and the elongation at break does not exceed 7%; the crossing yarn 11 adopts rigid untwisted PI filaments with a smooth surface friction coefficient of 0.21.

[0066] like figure 2 As shown, the tubular fabric 1 is characterized by:

[0067]①The el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com