Lock catch mechanism of hoarding box

A locking mechanism and coaming box technology, which is applied to rigid containers, containers, packaging, etc., can solve the problem that the volume cannot be adjusted, and achieve the effects of simple and convenient operation, low manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

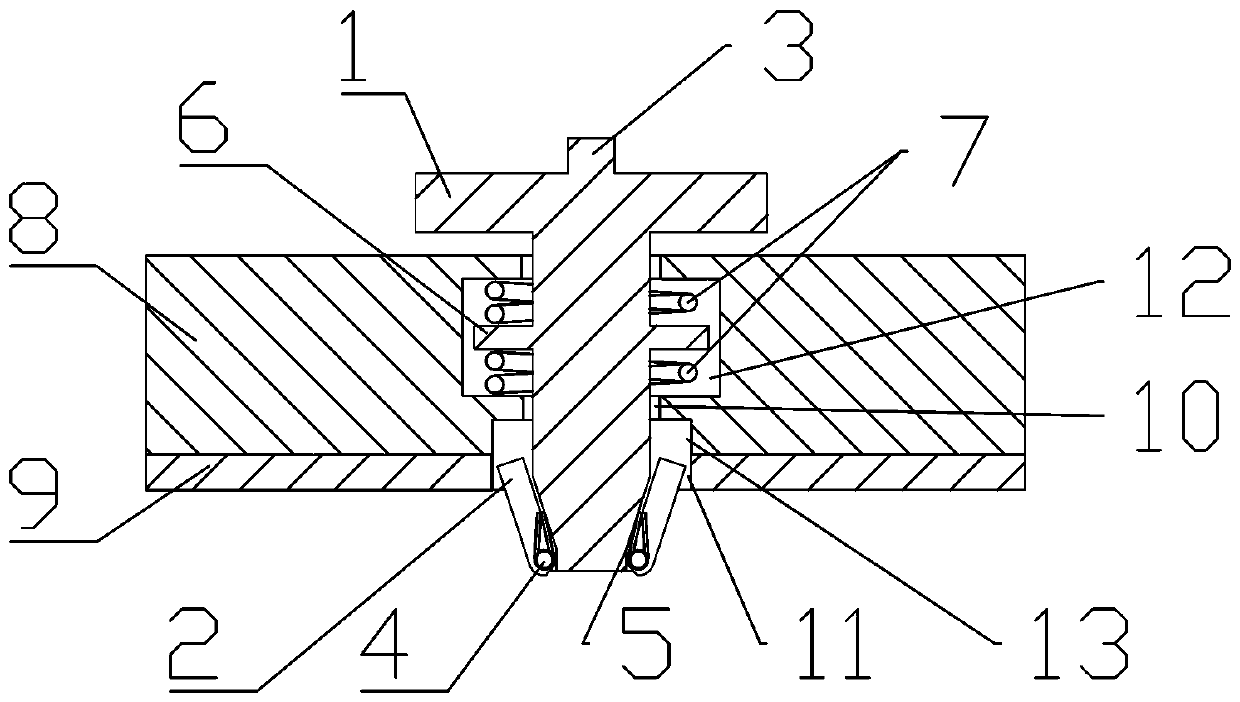

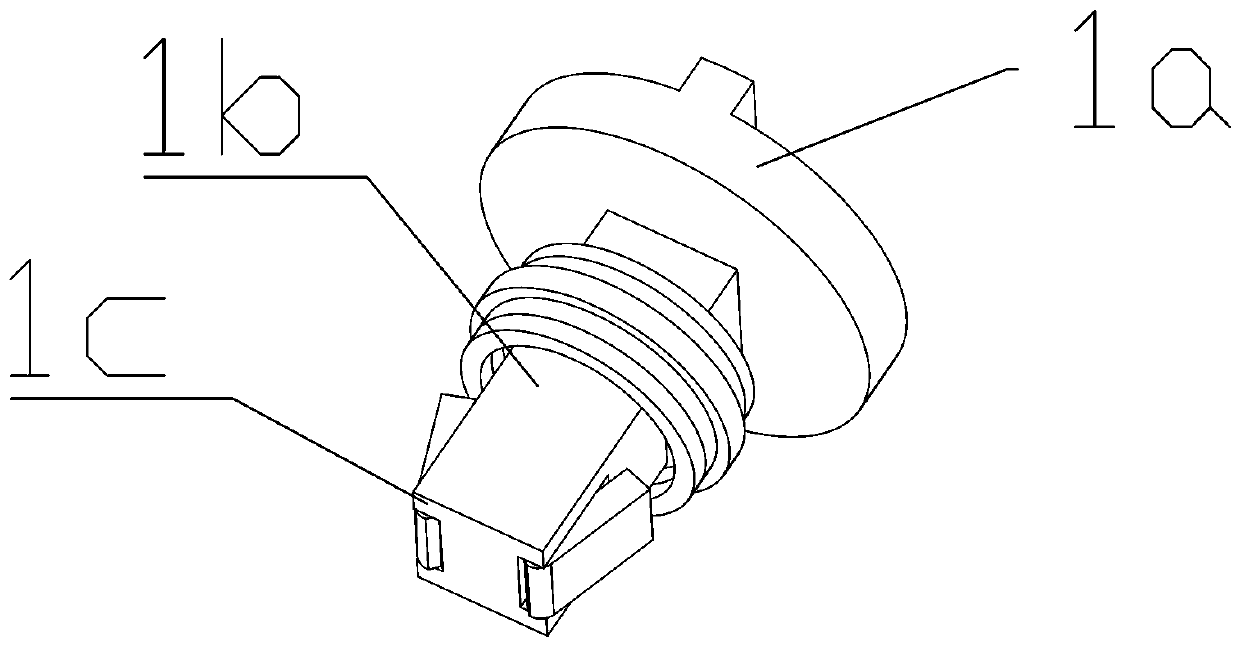

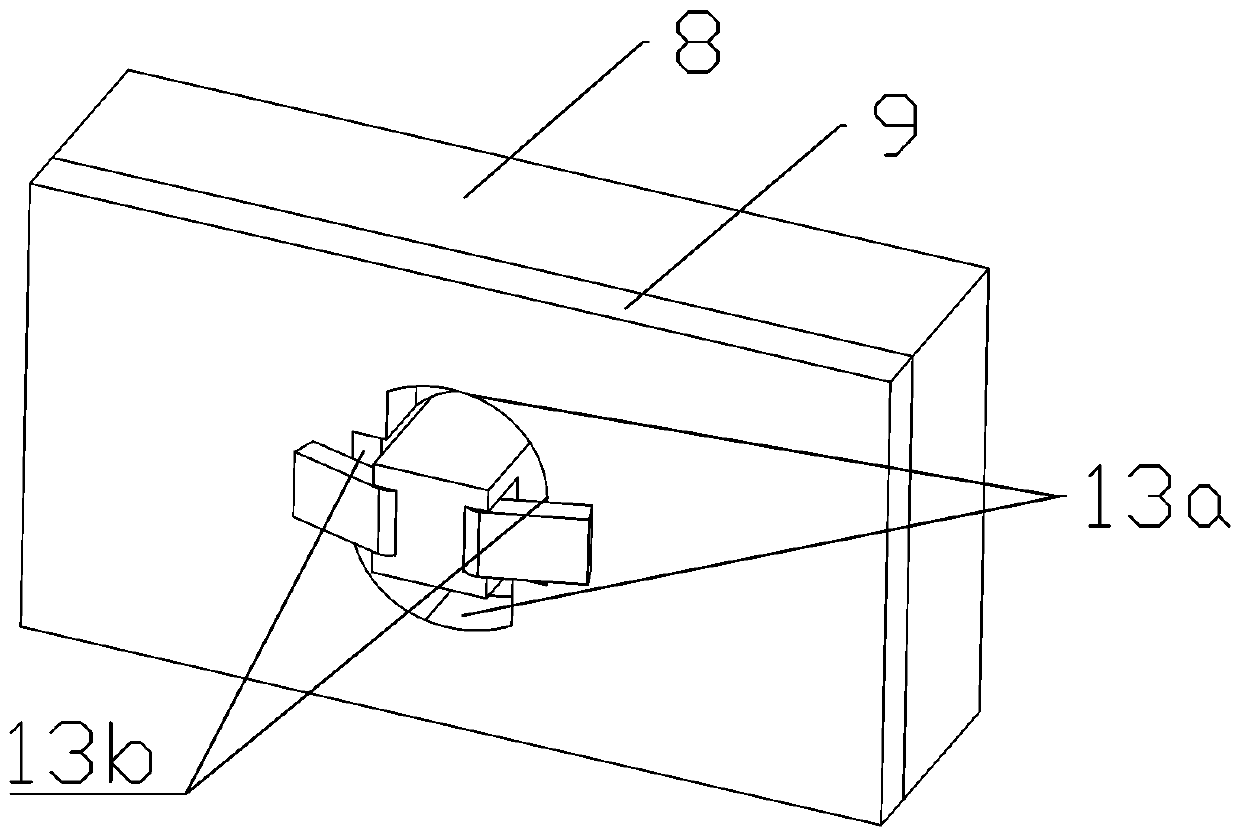

[0017] refer to Figure 1 to Figure 5 As shown, the coaming box locking mechanism includes a locking nail 1 and a blocking block 2. The head 1a of the locking nail is provided with a rotating protrusion 3, and the part combining the lower part 1b of the locking nail and the blocking block is a rectangular parallelepiped structure. The nail is installed on the cover of the coaming box and protrudes from the side wall of the box cover. The tail part 1c of the locking nail is hingedly connected to the blocking block, and the hinge 4 of the hinged connection is sleeved with a V-shaped spring 5. The surface of the nail 1 and the blocking block 2 are bonded together, and there is a cylindrical protrusion 6 in the middle of the locking nail. The upper end surface and the lower end surface of the protrusion are respectively pressed with springs 7, and the springs are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com