Fine-grain strengthening and enhancing device for surface of steel tube tower component

A fine-grain strengthening and strengthening device technology, which is applied in the field of surface treatment devices for semi-finished steel pipe tower components, can solve the problems of unfavorable processing and production, reduce elongation and yield strength, etc., achieve strength improvement without affecting elongation and yield strength, and improve The effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

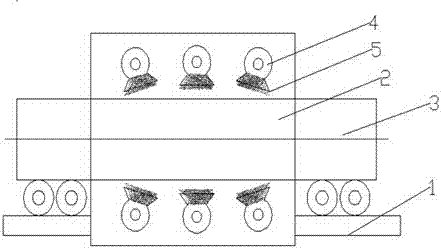

[0011] The front view of the present invention is as figure 1 As shown, it includes a conveying support 1, and the workpiece 3 moves along the conveying support 1 through rollers; a fine-grain processing chamber 2 surrounding the workpiece 3 is arranged on the moving route of the workpiece 3, and several surrounding work 3 are installed in the fine-grain processing chamber 2. Distributed fine grain processor4.

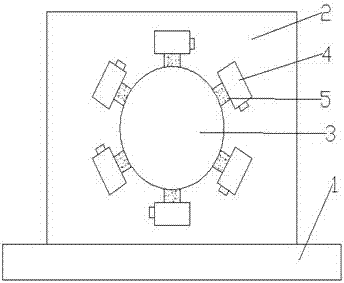

[0012] The side view of the present invention is as figure 2 As shown, a group of six fine grain processors 4 are equidistantly distributed along the outer circumference of the workpiece 3 .

[0013] The main working principle: a special device is designed to complete the high-speed particle 5 hitting on the flat surface of the steel pipe tower or other long workpieces in a relatively closed fine-grain treatment chamber, so that the grains on the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com