Radial shrink-expandable tubular fabric coupled with structural phase transition and cross-rotation, its preparation method and application

A technology of phase transformation and fabric, applied in the direction of fabric, weaving, textile and papermaking, etc., can solve the problems not related to the preparation method and application provided by the present invention, and not related to tube fabric, etc., to achieve good maintenance, high sampling rate, low The effect of tensile elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

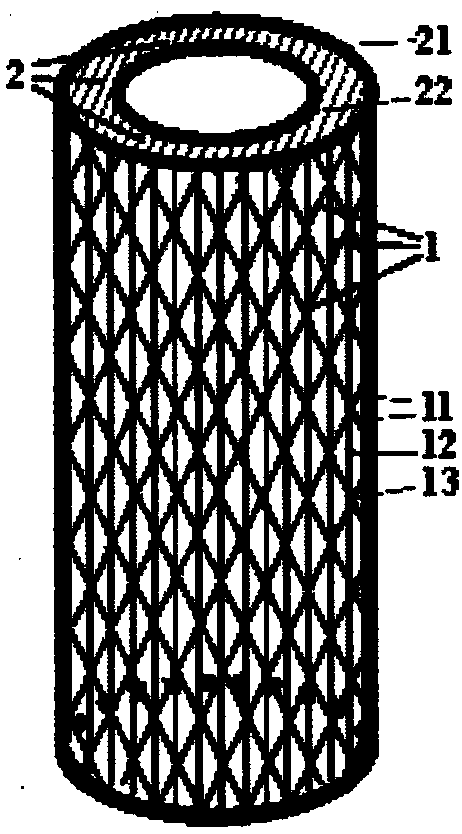

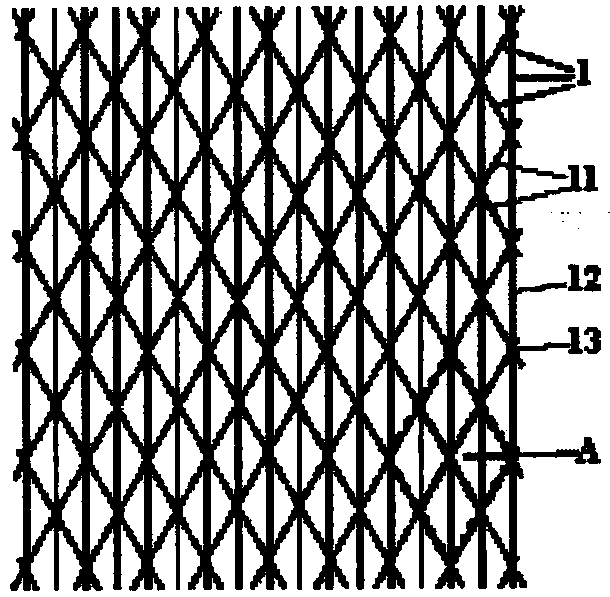

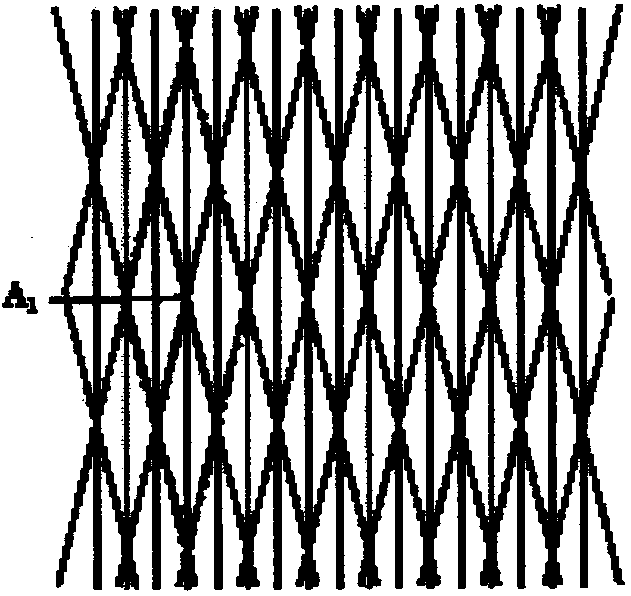

[0034] Such as figure 1 , 2a As shown in -e, it is a radial contraction-expandable tubular fabric with structural phase transition and cross-rotation coupling. The tubular fabric 1 is made of high-modulus linear elastic warp yarns 12 and soft cross-braided yarns 11 that cross each other symmetrically. The weaving method forms a structurally stable, radially expandable thin tubular fabric.

[0035] The two groups of cross-knitting yarns 11 all use fine-denier weakly twisted crimped Nomex filament yarns, and their own elongation at break does not exceed 8%, and can be flattened and densified during structural phase transition.

[0036] The value of the intersection angle θ when forming between two groups of cross braided wires 11 is 90 °; because the relationship between the cross angle θ and the helix angle φ of the two cross braided wires 11 helices is: θ=180 °-2φ, so the helix angle φ is 45°.

[0037] The warp 12 adopts twisted high-strength and high-modulus optical filame...

Embodiment 2

[0047] Such as figure 1 , 2a As shown in -e, it is a radial contraction-expandable tubular fabric with structural phase transition and cross-rotation coupling. The tubular fabric 1 is made of high-modulus linear elastic warp yarns 12 and soft cross-braided yarns 11 that cross each other symmetrically. The weaving method forms a structurally stable, radially expandable thin tubular fabric.

[0048] The two groups of cross-knitting yarns 11 are all made of fine denier and weakly twisted crimped PBO filament yarns, and their own elongation at break is not more than 8%, and can be flattened and densified during structural phase transition.

[0049] The value of the intersection angle θ when forming between two groups of cross braided wires 11 is 100 °; because the relationship between the cross angle θ and the helix angle phi of the two cross braided wires 11 helices is: θ=180 °-2φ, so the helix angle φ is 40°.

[0050] The warp 12 adopts twisted high-strength and high-modulus ...

Embodiment 3

[0060] Such as figure 1 , 2a As shown in -e, it is a radial contraction-expandable tubular fabric with structural phase transition and cross-rotation coupling. The tubular fabric 1 is made of high-modulus linear elastic warp yarns 12 and soft cross-braided yarns 11 that cross each other symmetrically. The weaving method forms a structurally stable, radially expandable thin tubular fabric.

[0061] The two groups of cross-knitting yarns 11 are all made of fine denier and weakly twisted crimped PI filament yarns, and their own elongation at break does not exceed 8%, and can be flattened and densified during structural phase transition.

[0062] The value of the intersection angle θ when forming between two groups of cross braided wires 11 is 120 °; because the relationship between the cross angle θ and the helix angle phi of the two cross braided wires 11 helices is: θ=180 °-2φ, so the helix angle φ is 30°.

[0063]The warp 12 adopts twisted high-strength and high-modulus opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com