Structural phase transition radial expansion tube fabric based on soft weft and its preparation

A phase transition and fabric technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of uninvolved tube fabrics, uninvolved, etc., and achieve the effect of good retention and high sampling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

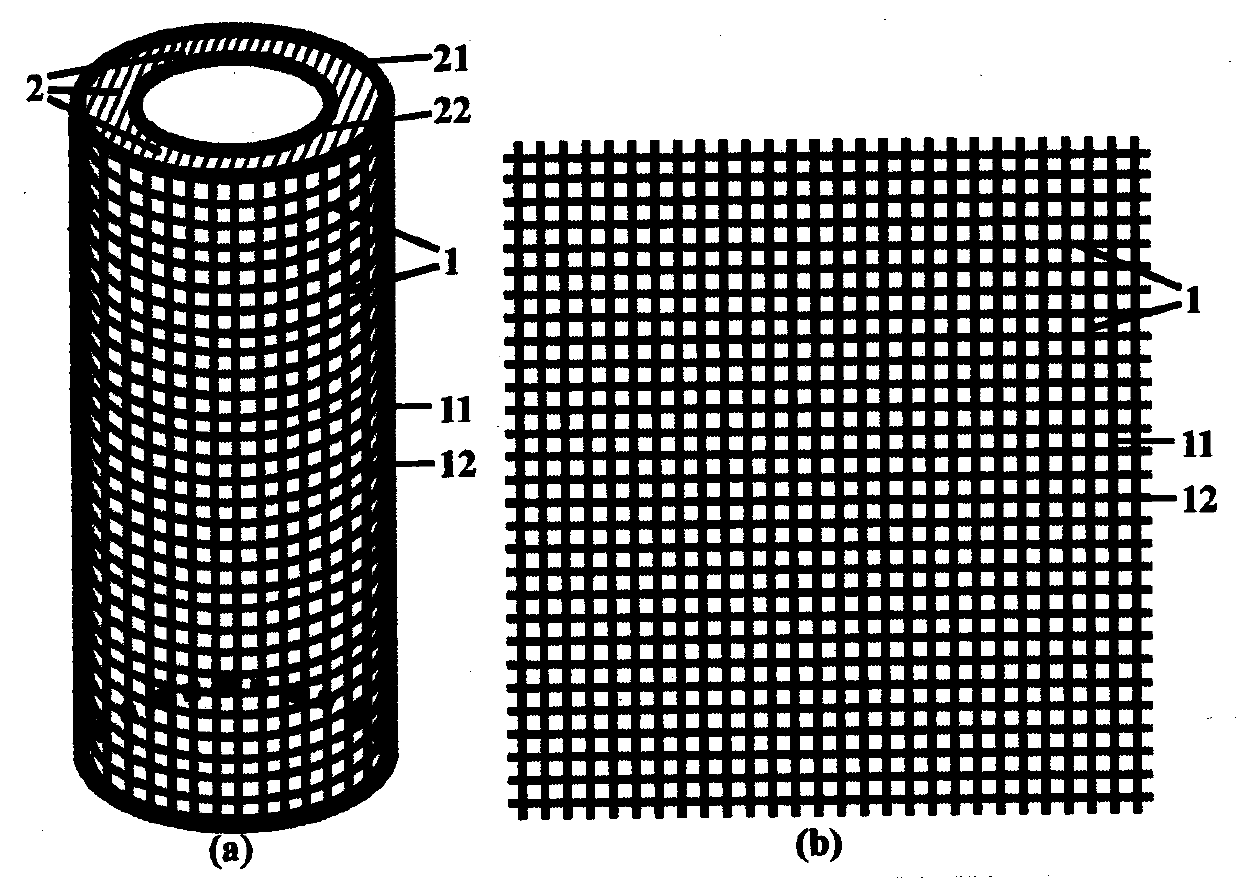

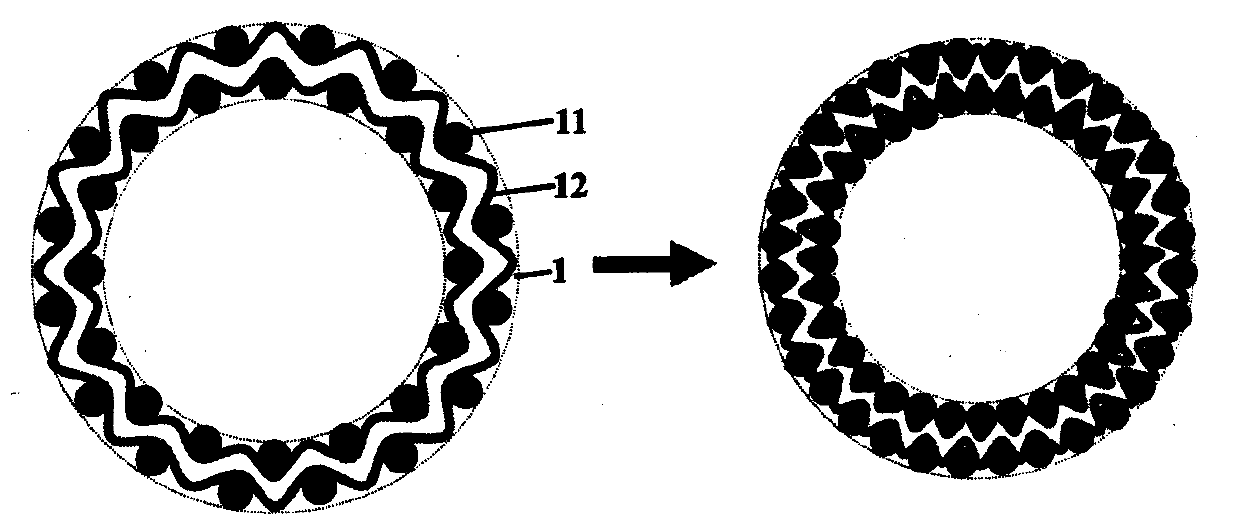

[0036] Such as figure 1 As shown, the soft weft-based structural phase-change radial shrinkage-expandable tubular fabric of this embodiment is formed by weaving and weaving the soft weft 12 and the warp 11 with high machine tension in the form of double-layer fabric weaving. The tubular structure fabric 1 capable of radial expansion, when the tubular structure fabric is coated on the outer wall of the round tube, the tubular structure fabric is subjected to the top expansion force of the outer wall of the round tube under the action of stretching, and the weft yarn 12 It can be naturally straightened to grow and flatten, so that the tubular structural fabric 1 changes from the weft support surface to the warp support surface, and the diameter of the tubular structural fabric 1 increases, thereby reducing the pull-out resistance when the tubular structural fabric 1 is covered.

[0037] The warp 11 of the tubular structure fabric 1 is made of twisted light Kevlar filament circul...

Embodiment 2

[0051] Such as figure 1 As shown, the soft weft-based structural phase transition type radial shrinkable tubular structure fabric of this embodiment adopts double-layer fabric weaving form to introduce soft weft 12 and high machine tension warp 11 into weaving form The tubular structure fabric 1 capable of radial expansion, when the tubular structure fabric is coated on the outer wall of the circular tube, the tubular structure fabric is subjected to the top expansion force of the outer wall of the circular tube under the action of stretching, and the weft yarn 12 can naturally straighten and grow and flatten, so that the tubular structure fabric 1 changes from the weft support surface to the warp support surface, and the diameter of the tubular structure fabric 1 increases, thereby reducing the pull-out resistance when the tubular structure fabric 1 is covered.

[0052] The warp 11 of the tubular structure fabric 1 is made of twisted light Kevlar filament circular multifilame...

Embodiment 3

[0066] Such as figure 1 As shown, the soft weft-based structural phase transition type radial shrinkable tubular structure fabric of this embodiment adopts double-layer fabric weaving form to introduce soft weft 12 and high machine tension warp 11 into weaving form The tubular structure fabric 1 capable of radial expansion, when the tubular structure fabric is coated on the outer wall of the circular tube, the tubular structure fabric is subjected to the top expansion force of the outer wall of the circular tube under the action of stretching, and the weft yarn 12 can naturally straighten and grow and flatten, so that the tubular structure fabric 1 changes from the weft support surface to the warp support surface, and the diameter of the tubular structure fabric 1 increases, thereby reducing the pull-out resistance when the tubular structure fabric 1 is covered.

[0067] The warp 11 of the tubular structure fabric 1 is made of twisted light Kevlar filament circular multifilame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com