C9 solid petroleum resin preparation method

A technology of solid petroleum resin and petroleum resin, which is applied in the field of preparation of C9 solid petroleum resin, can solve the problems that the reaction solution is not easy to emulsify, is not suitable for popularization and application, and the production cost of petroleum resin is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

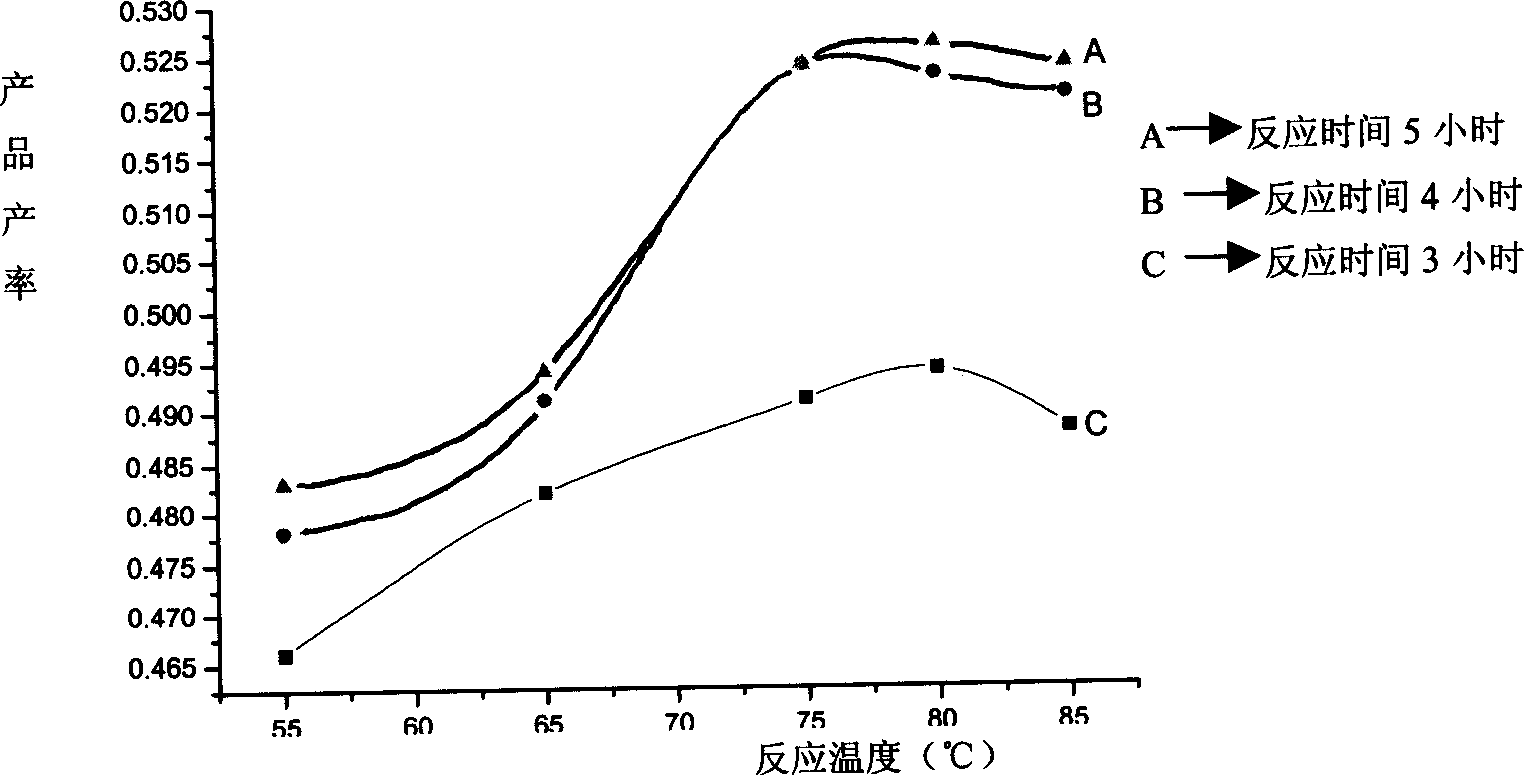

Embodiment 1

[0041] By-product C from the ethylene cracking unit of Lanzhou Chemical Industry Company 9 Distillate as raw material, the C 9 Fractions are collected by distillation under reduced pressure at 0.08Mpa at 90°C 9 Fractions, choose these C 9 Fraction as C 9 The reaction raw material of petroleum resin; In the reactor with agitation (60W, 3000 rev / mins, Changzhou Guohua Motor Co., Ltd.), temperature control is added successively below 30 ℃ and is 10% maleic anhydride, 89% C 9 Distillate, and 1% BF 3 -ether complex, heat up after feeding, react at 80°C for 3 hours to obtain a polymerization solution; add the polymerization solution to a 5% NaOH solution and soak for 25 minutes, and then wash with 75°C hot water, Alkali washing-water washing is carried out alternately until the polymerization liquid is washed to neutral; the polymerization liquid is heated under a vacuum of 0.08MPa, and when the temperature rises to about 120°C, it stops rising, and when the temperature drops a...

Embodiment 2

[0043] By-product C from the ethylene cracking unit of Lanzhou Chemical Industry Company 9 Distillate as raw material, the C 9 The raw material is distilled under reduced pressure under the pressure of 0.09Mpa to collect 110°C C 9 Fractions, choose these C 9 Fraction as C 9 Reaction raw material of petroleum resin; in a reactor with stirring, the temperature is controlled below 30°C and sequentially added 2% maleic anhydride, 97% C 9 Distillate, and 1% BF 3 -ether complex, heat up after feeding, react at 70°C for 5 hours to obtain a polymerization solution; add the polymerization solution to a 5% NaOH solution and soak for 30 minutes, and then wash with hot water at 65°C, Alkaline washing-water washing is carried out alternately until the polymerization liquid is washed to neutrality; the polymerization liquid is heated under a vacuum of 0.095MPa, and when the temperature rises to about 120°C, it stops rising, and when the temperature drops again, the distillation is stopp...

Embodiment 3

[0045] By-product C from the ethylene cracking unit of Lanzhou Chemical Industry Company 9 Distillate as raw material, the C 9 The raw material is distilled under reduced pressure at 0.085Mpa to collect 120°C C 9 Fractions, choose these C 9 Fraction as C 9 Reaction raw material of petroleum resin; in a reactor with stirring, the temperature is controlled below 30°C and sequentially added 6% maleic anhydride, 93.8% C 9 Distillate and 0.2% BF 3 -ether complex, heat up after the feeding is completed, react at 50°C for 4 hours to obtain a polymerization solution; add the polymerization solution to a 5% NaOH solution and soak for 35 minutes, and then wash with 70°C hot water, Alkali washing-water washing is carried out alternately until the polymerization liquid is washed to neutral; the polymerization liquid is heated under a vacuum of 0.09MPa, and when the temperature rises to about 120°C, it does not rise again, and when the temperature drops again, the distillation is stopp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com