High-molecular-weight MQ silicon resin and synthesis method and application thereof

A technology of MQ silicone resin and high molecular weight, which is applied in the field of high molecular weight MQ silicone resin and its synthesis, can solve the problems of low yield of MQ silicone resin, unreasonable purification method, and a large amount of waste water, etc. The effect of long retention time and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

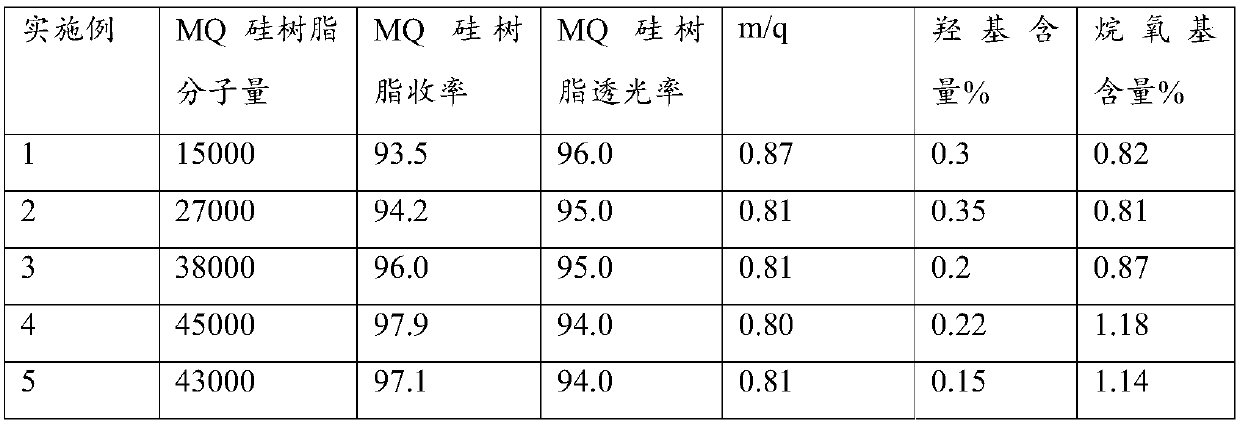

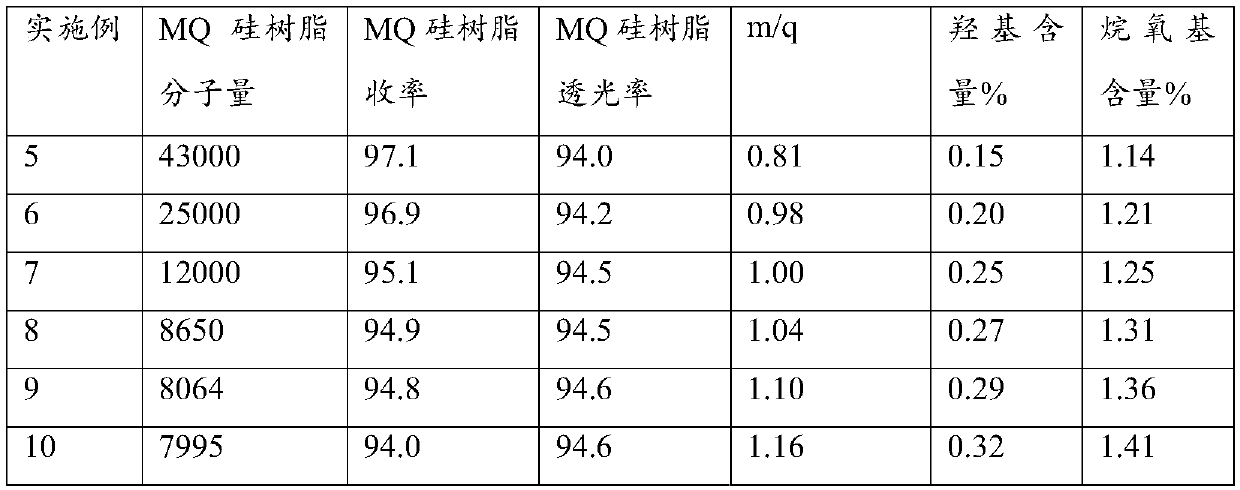

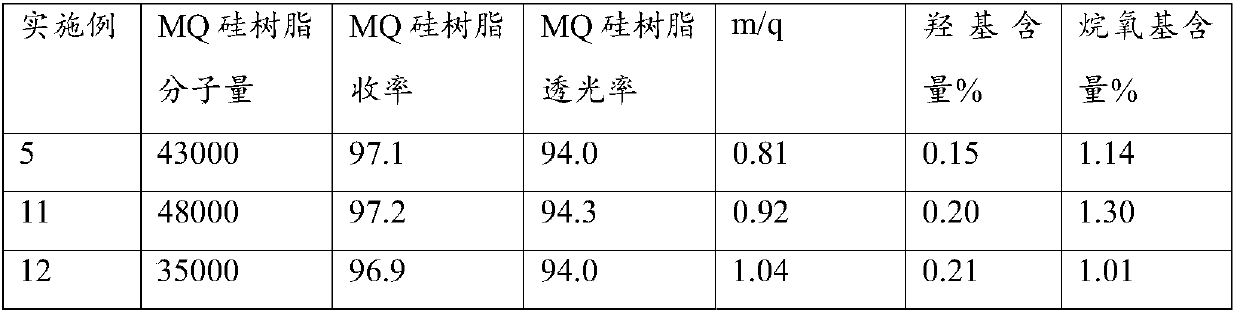

Examples

Embodiment 1

[0064] 1) Add 250 grams of deionized water, 50 grams of hydrochloric acid, 500 grams of ethanol, 70 grams of hexamethyldisiloxane, and 70 grams of divinyltetramethyldisiloxane into a four-necked flask with a condenser tube, a thermometer and a constant pressure dropping funnel. 5 grams of siloxane, start stirring, and raise the temperature to 30°C;

[0065] 2) Add 1055 grams of tetraethyl orthosilicate dropwise for 1 hour, and then heat-preserve and hydrolyze for 1 hour after adding;

[0066] 3) Heat up to 60°C, add a mixture of 650 grams of xylene, 350 grams of hexamethyldisiloxane and 24 grams of divinyltetramethyldisiloxane, and continue to keep warm for 4 hours; then add 650 grams of xylene, static separation;

[0067] 4) Add 30 grams of sodium bicarbonate to the organic phase, adjust the pH to 7, slowly raise the temperature to 150° C., remove low boilers at the same time, and then keep warm for 1 hour;

[0068] 5) Cool to room temperature, filter to remove insoluble ma...

Embodiment 2

[0070] 1) Add 250 grams of deionized water, 50 grams of acetic acid, 500 grams of isopropanol, 40 grams of hexamethyldisiloxane, and divinyltetramethyl to a four-neck flask with a condenser tube, a thermometer and a constant pressure dropping funnel. 5 grams of base disiloxane, start stirring, and heat up to 20-30°C;

[0071] 2) 771 grams of methyl orthosilicate was added dropwise, the dropwise addition time was 1 hour, and the temperature was kept at 20-30°C for 1 hour;

[0072] 3) Raise the temperature to 70°C, add a mixture of 650 grams of toluene, 350 grams of hexamethyldisiloxane and 24 grams of divinyltetramethyldisiloxane, and continue to keep warm for 3 hours; then add 650 grams of toluene and let stand Liquid separation;

[0073] 4) Add 30 grams of sodium bicarbonate to the organic phase, adjust the pH to 7, slowly raise the temperature to 110° C., remove low boilers at the same time, and then keep warm for 1 hour;

[0074] 5) Cool to room temperature, filter to rem...

Embodiment 3

[0076] 1) Add 200 grams of deionized water, 10 grams of trifluoromethanesulfonic acid, and 480 grams of methanol into a four-neck flask with a condenser, a thermometer and a constant pressure dropping funnel, raise the temperature to 45°C, and add hexamethyldisiloxane 30 grams, 5 grams of divinyltetramethyldisiloxane;

[0077] 2) Add 1340 grams of propyl orthosilicate dropwise, dropwise for 2.5 hours, and keep warm for 1 hour;

[0078] 3) Raise the temperature to 65°C, add a mixture of 750 grams of toluene, 360 grams of hexamethyldisiloxane and 24 grams of divinyltetramethyldisiloxane, and continue to keep warm for 4 hours; then add 750 grams of toluene and let stand Liquid separation;

[0079] 4) Add 30 grams of sodium bicarbonate to the organic phase, adjust the pH to 7.0, slowly raise the temperature to 120° C., remove low boilers at the same time, and keep the temperature for 3 hours;

[0080] 5) Cool to room temperature, filter to remove insoluble matter, and remove the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com