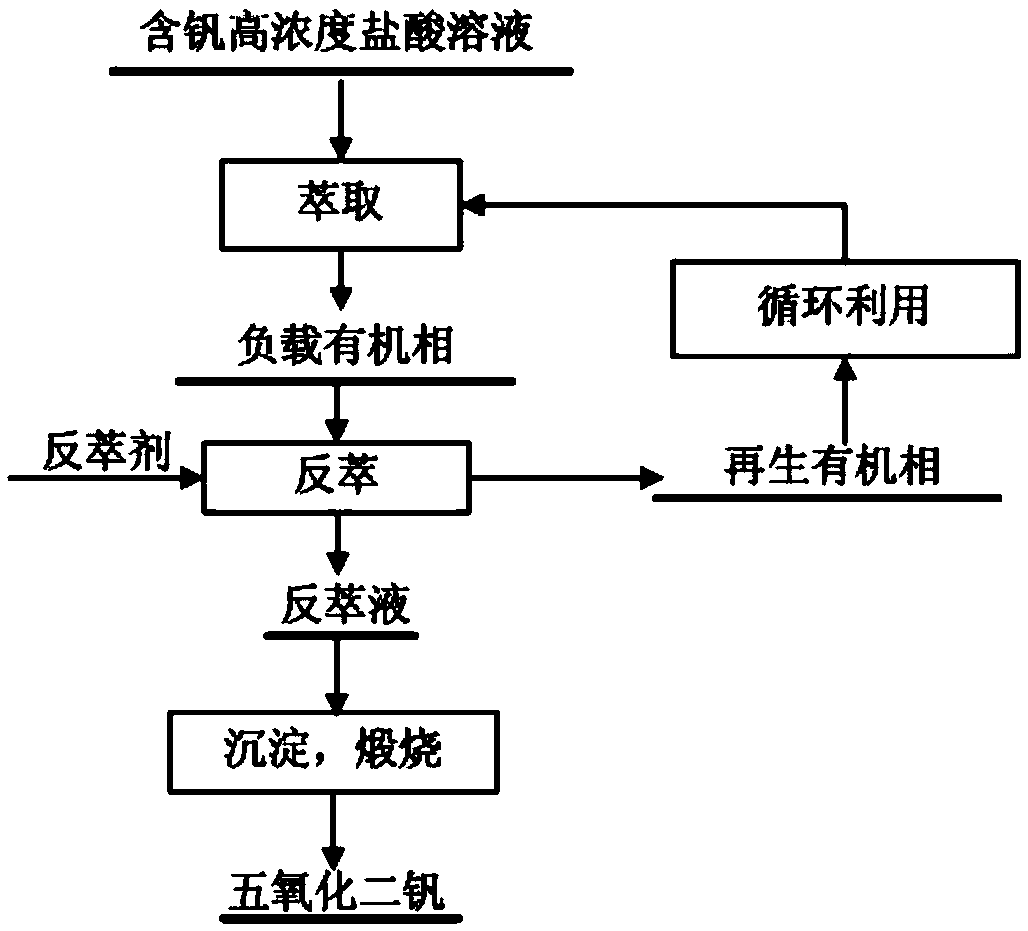

Method for extracting vanadium from vanadium-containing high-concentration hydrochloric acid solution

A hydrochloric acid solution, high-concentration technology, applied in the field of vanadium extraction, can solve problems such as no patents or literature reports, and achieve the effects of recycling, mild reaction conditions, and large separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The volume ratio of the vanadic acid immersion solution containing the concentration of hydrochloric acid 2.5mol / L and the composite organic extractant (amine extractant (trioctylmethylammonium chloride) and neutral extractant (tributyl phosphate)) is 1: 1) Mixing for extraction, the volume ratio of the composite organic extractant to the vanadium-containing high-concentration hydrochloric acid solution is 3:1, use 260# solvent oil as the diluent, the concentration of the composite organic extractant is 10%, the extraction time is 15min, and the extraction temperature The temperature is 15°C, and the phases are separated after standing; the vanadium-loaded organic phase is mixed with the stripping agent 1.0mol / L hydrochloric acid solution for stripping, the volume ratio of the vanadium-loaded organic phase to the stripping agent is 10:1, and the stripping time is 30min, the stripping temperature is 15°C, after standing still, the phases are separated to obtain the upper ...

Embodiment 2

[0030] The volume ratio of the vanadium-containing acid immersion solution with a hydrochloric acid concentration of 4.5mol / L and the composite organic extractant (amine extractant (trioctylmethylammonium chloride) and neutral extractant (trioctylphosphine oxide)) is 1 :8) mixing and extracting, the volume ratio of the composite organic extractant to the vanadium-containing high-concentration hydrochloric acid solution is 1:10, using sulfonated kerosene as a diluent, the concentration of the composite organic extractant is 70%, and the extraction time is 0.1min. The temperature is 65°C, and the phases are separated after standing; the vanadium-loaded organic phase is mixed with the stripping agent 1.0mol / L sulfuric acid solution for stripping, the volume ratio of the vanadium-loaded organic phase to the stripping agent is 1:5, and the stripping time The extraction temperature is 0.2min, the stripping temperature is 65°C, and the upper organic phase and the stripping liquid are ...

Embodiment 3

[0032] The vanadium-containing acid immersion solution with a hydrochloric acid concentration of 2.5mol / L was mixed with a compound organic extractant (amine extractant (trioctylmethylammonium chloride) and neutral extractant (trioctylphosphine oxide and tributyl phosphate) 1:1 mixed) with a volume ratio of 3:7) for extraction, the volume ratio of the composite organic extractant to the vanadium-containing high-concentration hydrochloric acid solution is 2:1, using sulfonated kerosene as a diluent, and the concentration of the composite organic extractant is 50%, the extraction time is 15min, the extraction temperature is 30°C, and the phases are separated after standing; The ratio is 1:1, the stripping time is 10min, and the stripping temperature is 20°C. After standing still, the phases are separated to obtain the upper organic phase and the stripping liquid; After calcining at a temperature of 500°C for 4 hours, the product of vanadium pentoxide is obtained. The upper orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com