Gas separation method using sub-pressure swing adsorption

A pressure swing adsorption and gas separation technology, applied in separation methods, adsorption purification/separation, dispersed particle separation, etc., can solve the problems of difficult desorption and regeneration of trace impurities, high energy consumption, and inability to expand application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

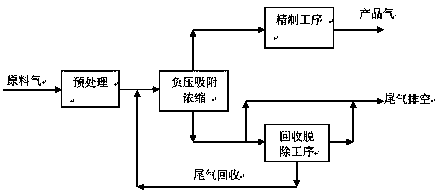

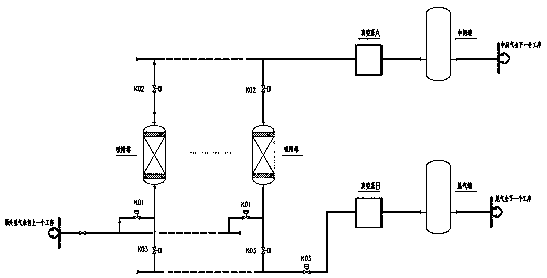

[0055] Such as figure 1 , 2 As shown, a negative pressure swing adsorption gas separation method is used to purify and remove hydrocarbons from natural gas to produce pure methane, including a pretreatment process, a negative pressure adsorption concentration process, a refining process, and a recovery and removal process:

[0056] 1) Pretreatment process

[0057] Preliminary removal of impurity components such as water, oil mist and hydrogen sulfide in the natural gas raw material gas, further washing through the washing tower, and then proceeding to the next step at room temperature;

[0058] 2) Negative pressure adsorption concentration process

[0059] Including 2 adsorption towers, 2 vacuum pumps A / B, 1 intermediate tank and 1 tail gas tank; natural gas enters the pressure swing adsorption unit from the bottom of the adsorption tower through the control valve K01 after being decompressed to normal pressure, and the top of the adsorption tower is connected with the vacuu...

Embodiment 2

[0067] Such as figure 1 , 2 As shown, a negative pressure swing adsorption gas separation method is used for the recovery of high-value components such as hydrogen, C2 and above light hydrocarbons in the refinery dry gas, including pretreatment, negative pressure adsorption concentration process, refining process and recovery and removal process; the raw gas of refinery dry gas is pretreated, dedusted, desulfurized and cooled to -40°C before entering the negative pressure adsorption concentration process; the negative pressure adsorption concentration process includes 6 adsorption towers, 2 vacuum pumps A / B, 1 intermediate tank and 1 tail gas tank; the refinery dry gas enters the pressure swing adsorption unit from the bottom of the adsorption tower through the control valve K01 after being decompressed to normal pressure, and the top of the adsorption tower is connected to the vacuum pump A with a pipeline and the control valve K02. When the vacuum pump A starts, a negative ...

Embodiment 3

[0071] Such as figure 1 , 2 As shown, a negative pressure swing adsorption gas separation method is used for the separation and purification of high alkyne in crude acetylene gas, including pretreatment, negative pressure adsorption concentration process, refining process and recovery and removal process; after pretreatment, the gas containing Crude acetylene gas with high alkynes above 20-200ppm, at a temperature of 5-80°C, is decompressed to normal pressure and enters the negative pressure adsorption concentration process from the bottom of the adsorption tower through the control valve K01. High-level alkynes and their trace impurities (hereinafter Collectively referred to as "high alkyne") as an adsorbate, is adsorbed by the adsorbent packed in the adsorption tower; acetylene is not adsorbed but flows out from the top of the adsorption tower to obtain acetylene content greater than 99.8~99.9% and high alkyne content less than 10~20ppm Acetylene products; this process incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com