Reaction system for removing hydrogen fluoride in hydrogen chloride

A reaction system, hydrogen fluoride technology, applied in chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, inorganic chemistry, etc., can solve the problems of poor defluorination effect and high difficulty in solid sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

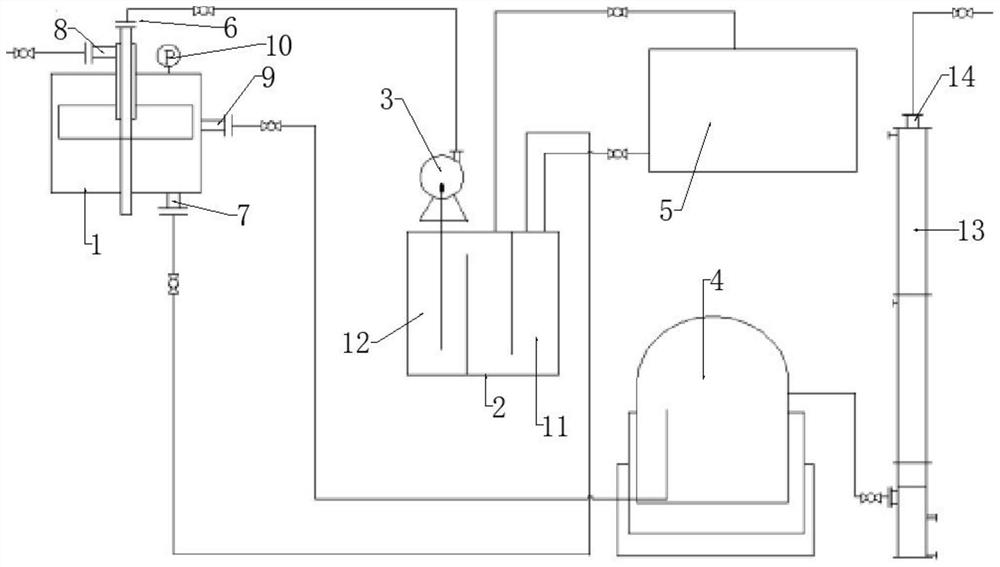

Method used

Image

Examples

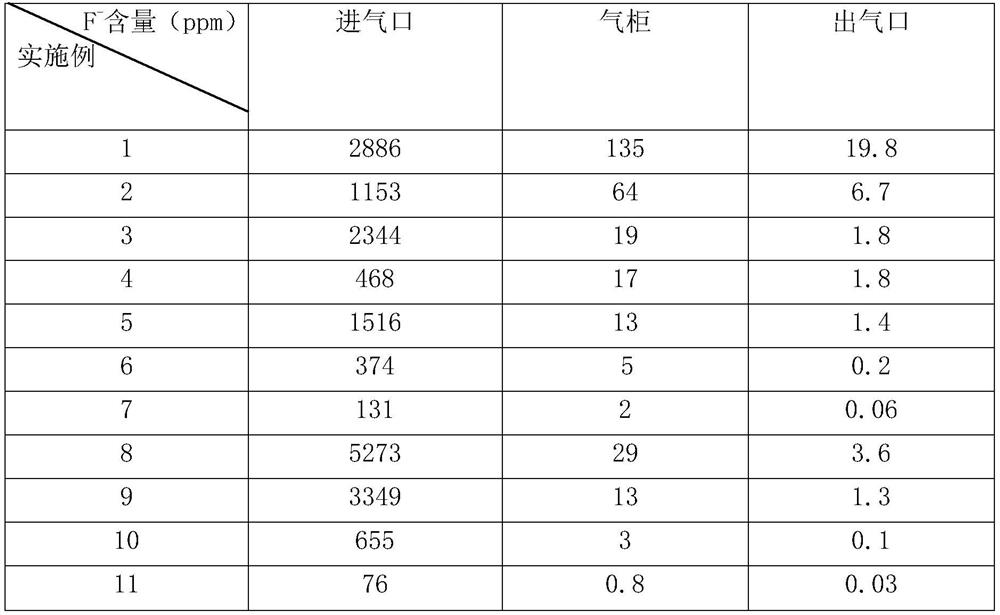

Embodiment 1

[0043] Prepare a 0.1mol / L magnesium chloride solution in the external circulation system, and add calcium hydroxide to make the concentration 0.1mol / L. Prepare a 5mol / L magnesium chloride solution in the feeding system, and add calcium hydroxide at the same time to make the concentration also 5mol / L. Turn on the metering pump to 10m 3 Pump the multi-component active defluoridation solution in the external circulation system into the supergravity separator at a speed of 5m / h 3 The hydrogen chloride gas stream containing fluorinated products is fed at a speed of / h and the hydrogen fluoride content of the inlet is sampled. The internal pressure of the supergravity separator is controlled to 1.3MPa, and the rotor speed is 300r / min. After the reaction, the multi-component active defluoridation solution returns to the external circulation system through the liquid outlet, the gas enters the gas cabinet, decompresses and removes water, controls the pressure of the gas cabinet to ab...

Embodiment 2

[0045] Prepare 0.1mol / L ferric chloride solution in the external circulation system, and add calcium hydroxide to make the concentration 0.1mol / L. Prepare 5mol / L ferric chloride solution in the feeding system, and add calcium hydroxide at the same time to make the concentration also 5mol / L. Turn on the metering pump to 10m 3 Pump the multi-component active defluoridation solution in the external circulation system into the supergravity separator at a speed of 5m / h 3 The hydrogen chloride gas stream containing fluorinated products is fed at a speed of / h and the hydrogen fluoride content of the inlet is sampled. The internal pressure of the supergravity separator is controlled to 1.3MPa, and the rotor speed is 300r / min. After the reaction, the multi-component active defluoridation solution returns to the external circulation system through the liquid outlet, the gas enters the gas cabinet, decompresses and removes water, controls the pressure of the gas cabinet to about 10kPa,...

Embodiment 3

[0047] Prepare a 0.1mol / L aluminum chloride solution in the external circulation system, and add calcium hydroxide to make the concentration 0.1mol / L. Prepare a 3mol / L aluminum chloride solution in the feeding system, and add calcium hydroxide at the same time to make the concentration also 3mol / L. Turn on the metering pump to 10m 3 Pump the multi-component active defluoridation solution in the external circulation system into the supergravity separator at a speed of 5m / h 3 The hydrogen chloride gas stream containing fluorinated products is fed at a speed of / h and the hydrogen fluoride content of the inlet is sampled. The internal pressure of the supergravity separator is controlled to 1.3MPa, and the rotor speed is 300r / min. After the reaction, the multi-component active defluoridation solution returns to the external circulation system through the liquid outlet, the gas enters the gas cabinet, decompresses and removes water, controls the pressure of the gas cabinet to abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com