Metal organic compound filled cross-linked polysiloxane pervaporation membrane and preparation method thereof

A technology for cross-linking polysiloxane and organic compounds, applied in the field of membrane separation, can solve the problems of difficulty in increasing separation factor and permeation flux at the same time, short membrane life, poor compatibility, etc., and achieves good production repeatability and membrane formation. Good compatibility and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a cross-linked polysiloxane pervaporation membrane filled with a metal organic compound comprises the following steps, and the formula ratio is by weight:

[0029] (1) After uniformly mixing 70 parts of hydroxyl-terminated polydimethylsiloxane, 0.15 parts of monobutyltin oxide catalyst, 10 parts of n-hexane, and 15 parts of vinyltriethoxysilane at 25°C, Reaction at ℃ for 3 hours to generate prepolymer;

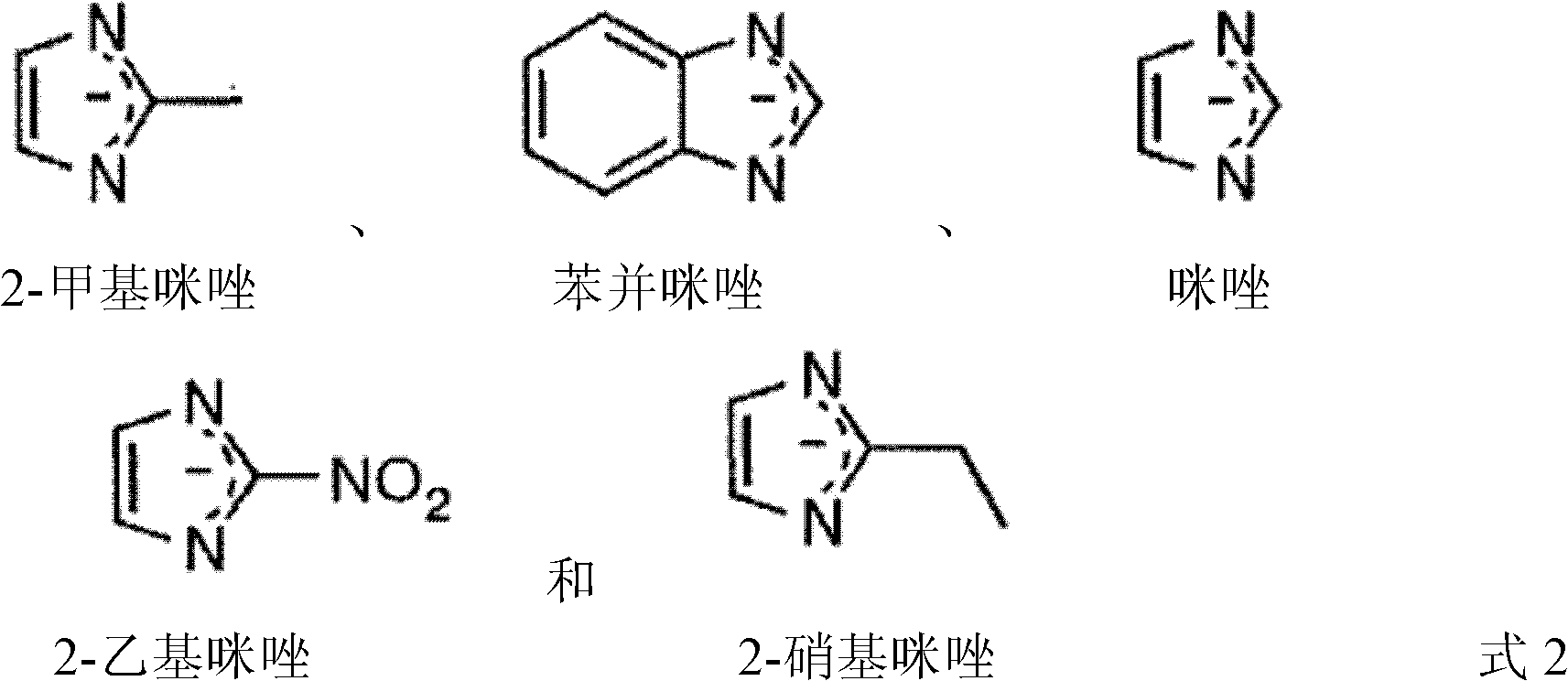

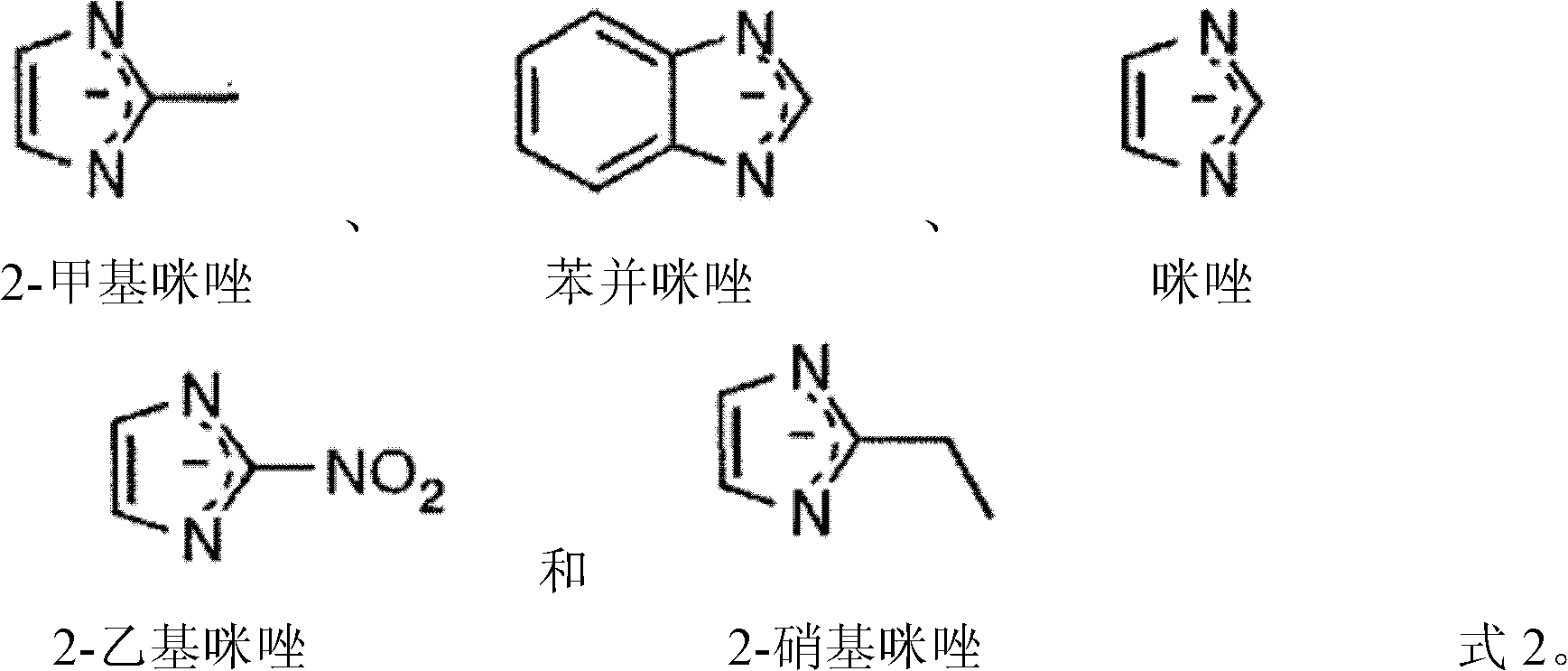

[0030] (2) Dissolve 3 parts of zinc nitrate and 3 parts of 2-methylimidazole in 100 parts of dimethylformamide, add 3 parts of triethylamine after heating to 80°C, react at 130°C for 6h, precipitate and filter with suction Afterwards, it was dried in an oven at 200°C for 10 hours to obtain a metal organic compound.

[0031] (3) Add 4.85 parts of metal-organic compound to the generated prepolymer, and react at 50°C for 3 hours to become a casting solution;

[0032] (4) Scrape-coat the above-mentioned casting solution on the polysulfone porous bot...

Embodiment 2

[0035] The preparation method of polysiloxane pervaporation membrane filled with metal organic compound comprises the following steps, and the formula ratio is by weight:

[0036] (1) After uniformly mixing 80 parts of hydroxyl-terminated polydimethylsiloxane, 0.1 part of dibutyltin dilaurate, 5 parts of toluene, and 10 parts of tetraethoxysilane at 30 ° C, at 80 ° C React for 1 hour to generate prepolymer;

[0037] (2) Dissolve 3 parts of cobalt nitrate and 12 parts of benzimidazole in 150 parts of dimethylformamide, add 6 parts of triethylamine after heating to 100°C, react at 160°C for 8 hours, and precipitate in the Dry in an oven at 260°C for 14 hours to obtain metal organic compounds.

[0038] (3) Add 4.9 parts of metal-organic compound to the generated prepolymer, and react at 80° C. for 1 hour to become a casting solution;

[0039] (4) Scrape-coat the above-mentioned casting solution on the polyvinylidene fluoride porous base film with a scraper, the thickness of the c...

Embodiment 3

[0042] A method for preparing a cross-linked polysiloxane pervaporation membrane filled with a metal organic compound comprises the following steps, and the formula ratio is by weight:

[0043] (1) After uniformly mixing 75 parts of vinyl-terminated polydiphenylsiloxane, 0.5 parts of dibutyltin oxide, 9 parts of tetrahydrofuran, and 12 parts of divinylbenzene at 27 ° C, react at 60 ° C for 2 hours generate prepolymers;

[0044] (2) Dissolve 3 parts of zinc nitrate and 5 parts of imidazole in 120 parts of dimethylformamide, add 4 parts of triethylamine after heating to 90°C, react at 140°C for 7 hours, precipitate and filter in an oven Dry at 240°C for 13 hours to obtain a metal organic compound.

[0045] (3) Add 3.5 parts of metal-organic compound to the generated prepolymer, and react at 60° C. for 2 hours to become a casting solution;

[0046] (4) Scrape-coat the above-mentioned casting solution on the polyethersulfone porous bottom membrane with a scraper, the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com