Dry-type graded concentration method for precious metal tenuousness grainy tailings

A technology of precious metals and fine particles, applied in classification, chemical instruments and methods, solid separation, etc., to achieve the effects of high sorting efficiency, good environmental protection, improved recovery rate and comprehensive recovery level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

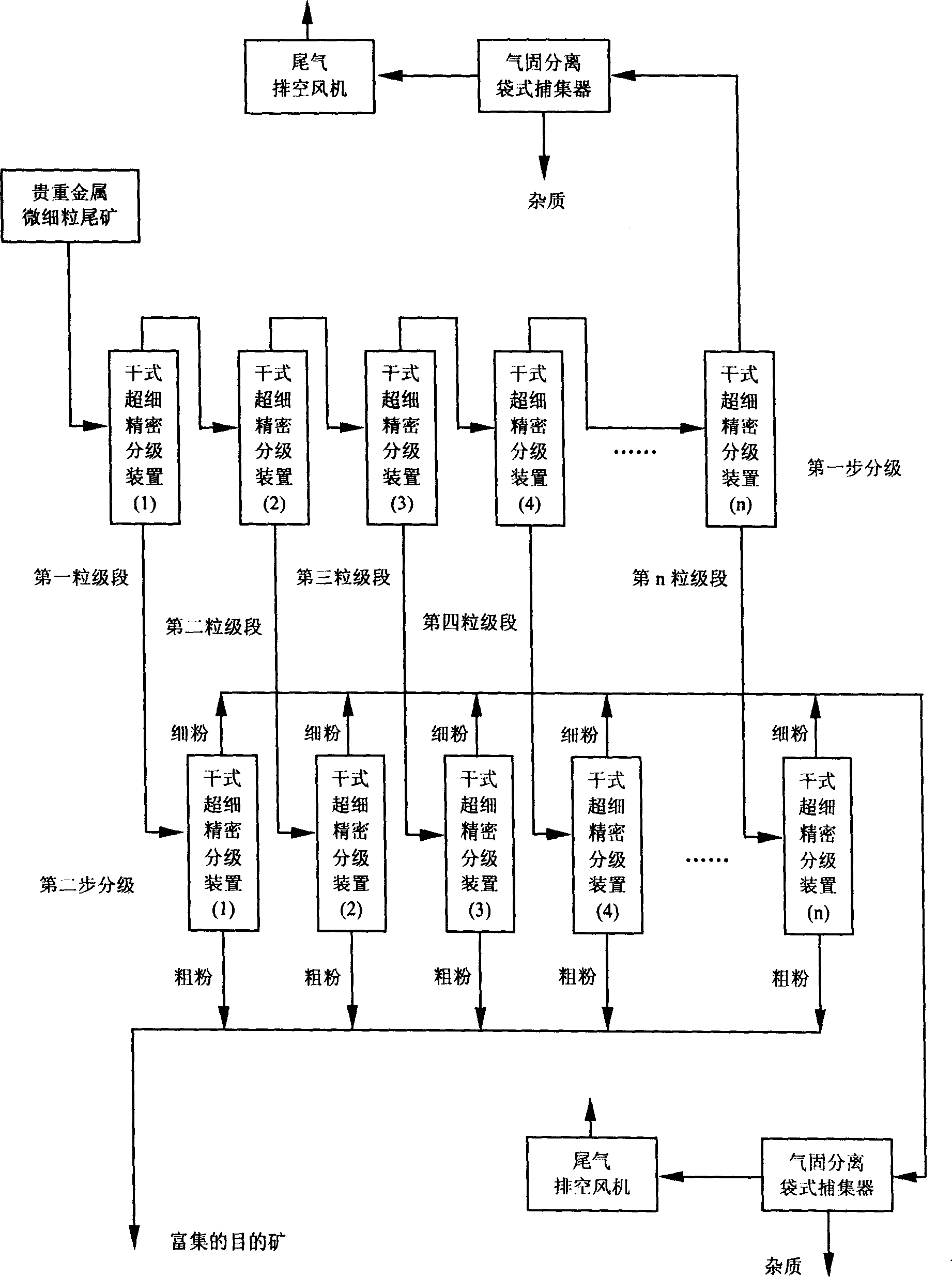

[0013] The present invention is implemented in the following manner:

[0014] (1) Pretreatment of precious metal fine-grained tailings: magnetic separation and enrichment of tailings with magnetic (or weakly magnetic) substances followed by drying treatment, and non-magnetic tailings are directly dried to obtain a moisture content of ≤ 2 % of tailings powder; carry out particle size test on tailings powder, and get the particle size distribution range: d max ~ d min .

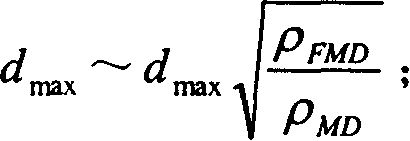

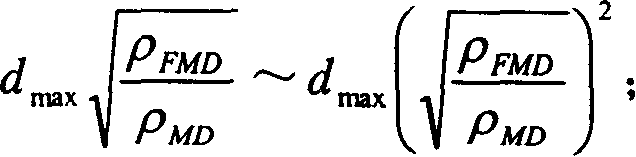

[0015] (2) Carry out the first step of dry classification on the dried tailings powder, and use a dry ultra-fine precision classification device to classify the precious metal fine-grained tailings powder into particle size structure classification, and divide it into n-grain segments. The grade structure conforms to the principle of equal velocity sedimentation and separation of target ore and non-target ore particles, specifically:

[0016] Particle size range of the first particle stage: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com