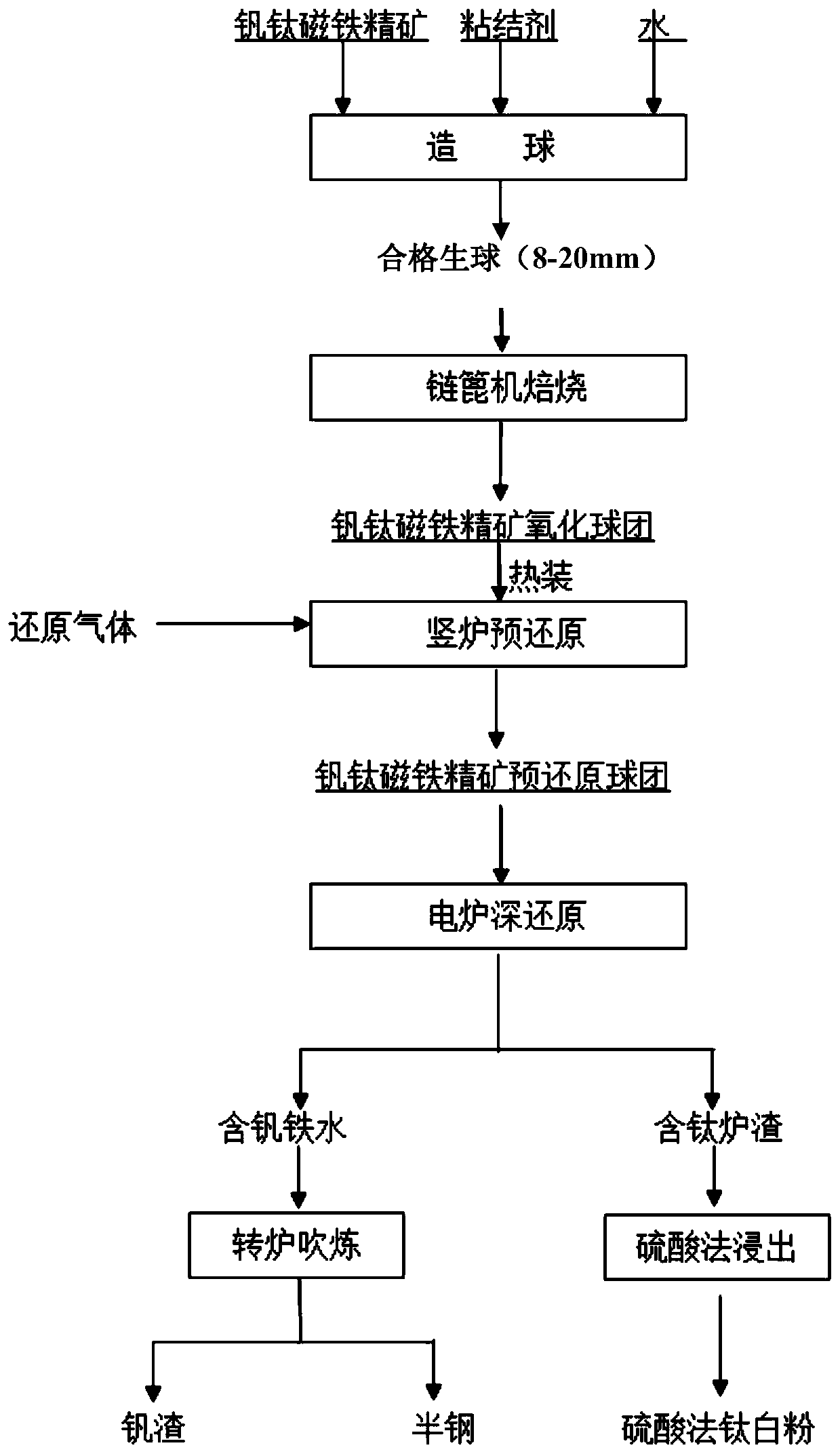

Process for comprehensively utilizing vanadium-titanium magnetite through chain grate roasting, gas-based shaft furnace prereduction, and electric furnace deep reduction

A technology for vanadium-titanium magnetite and vanadium-titanium-magnetite concentrate is applied in the field of comprehensive utilization of vanadium-titanium ore, and can solve the problems of high reduction and pulverization rate of vanadium-titanium magnetite oxidized pellets, low production efficiency, poor economic benefit and the like , to achieve the effect of improving energy utilization, improving production efficiency and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of chain grate roasting-gas-based shaft furnace pre-reduction-electric furnace deep reduction process for comprehensive utilization of vanadium-titanium magnetite, comprising the following steps:

[0028] (1) Preparation of oxidized pellets: Mix vanadium-titanium magnetite concentrate, binder, and water in proportion to make pellets to obtain qualified vanadium-titanium magnetite green pellets, and put the green pellets with a particle size of 8-20 mm into the chain Drying and oxidizing roasting in a grate machine, the drying temperature is 300°C, the oxidation roasting temperature is 950°C, and the oxidation roasting time is 60min to obtain vanadium-titanium magnetite oxidized pellets; the compressive strength of vanadium-titanium magnetite oxidized pellets 1326N / piece;

[0029] (2) Pre-reduction in gas-based shaft furnace: the vanadium-titanium-magnetite oxidized pellets are hot-loaded into the shaft furnace from the top, the hot-charging temperature is greater...

Embodiment 2

[0033] A kind of chain grate roasting-gas-based shaft furnace pre-reduction-electric furnace deep reduction process for comprehensive utilization of vanadium-titanium magnetite, comprising the following steps:

[0034] (1) Preparation of oxidized pellets: Mix vanadium-titanium magnetite concentrate, binder, and water in proportion to make pellets to obtain qualified vanadium-titanium magnetite green pellets, and put the green pellets with a particle size of 8-20 mm into the chain Drying and oxidizing roasting in a grate machine, the drying temperature is 400°C, the oxidation roasting temperature is 1050°C, and the oxidation roasting time is 40min to obtain vanadium-titanium magnetite oxidized pellets; the compressive strength of vanadium-titanium magnetite oxidized pellets is 1534N / piece;

[0035] (2) Gas-based shaft furnace pre-reduction: the vanadium-titanium-magnetite oxidized pellets are hot-loaded into the shaft furnace from the top, the hot-charging temperature is greate...

Embodiment 3

[0039] A kind of chain grate roasting-gas-based shaft furnace pre-reduction-electric furnace deep reduction process for comprehensive utilization of vanadium-titanium magnetite, comprising the following steps:

[0040](1) Oxidation pellet preparation: Mix vanadium-titanium magnetite concentrate, binder, and water in proportion to make pellets to obtain qualified vanadium-titanium magnetite green pellets, and put the green pellets with a particle size of 8-20mm into the chain Drying and oxidizing roasting in a grate machine, the drying temperature is 300 °C, the oxidation roasting temperature is 1150 °C, and the oxidation roasting time is 20 minutes to obtain vanadium-titanium magnetite oxidized pellets; the compressive strength of vanadium-titanium magnetite oxidized pellets 1754N / piece;

[0041] (2) Gas-based shaft furnace pre-reduction: the vanadium-titanium-magnetite oxidized pellets are hot-loaded into the shaft furnace from the top, the hot-charging temperature is greater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com