Low-yield-ratio and high strength thick plate and preparation process thereof

A technology with low yield ratio and preparation process, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of difficult control of laminar slow cooling method and poor steel production stability, and achieve easy control of production process and reduced production costs. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

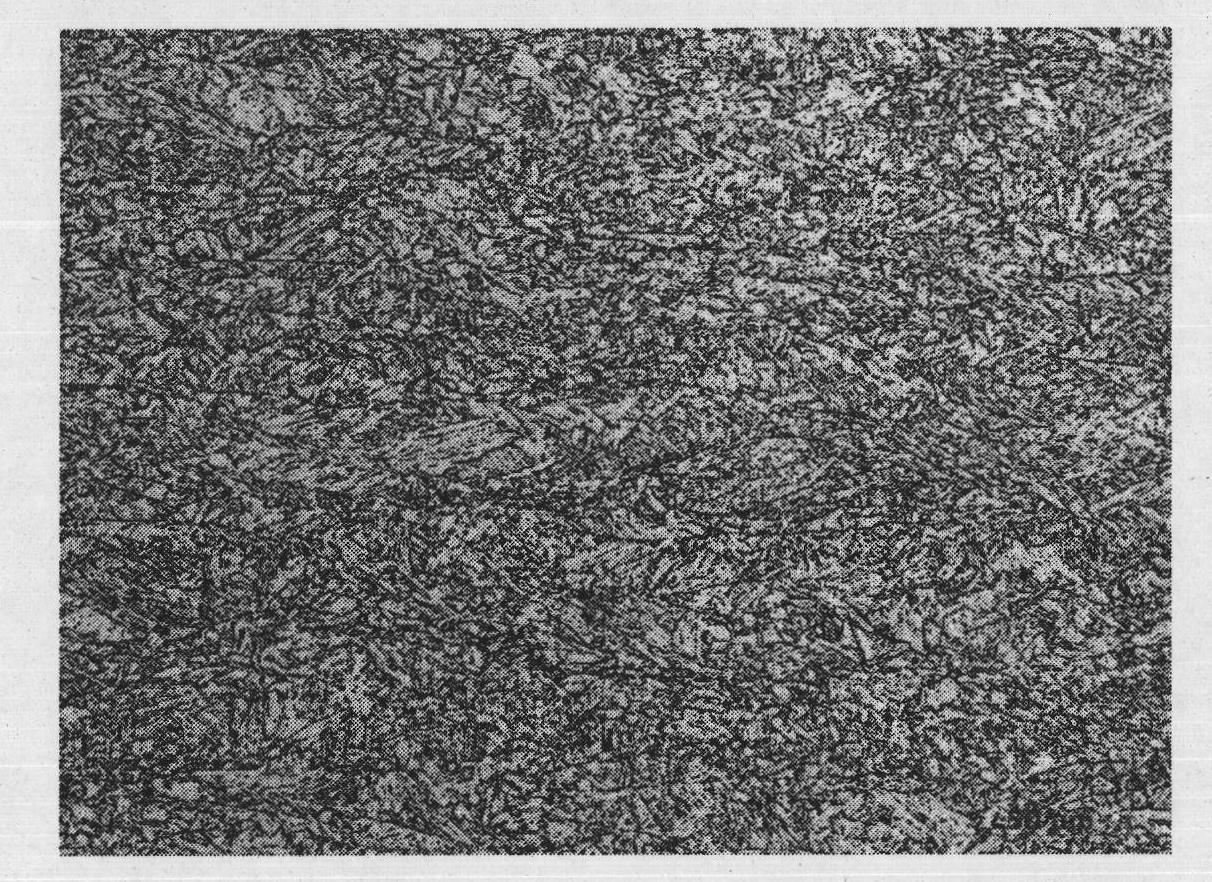

Embodiment 1

[0040] Example 1 The low-yield ratio high-strength thick plate of this example adopts the following composition design: C 0.06%, Si 0.22%, Mn 1.70%, Al 0.041%, Nb 0.062%, Ti 0.015%, Ni 0.34%, Cu 0.37%, Cr 0.20%, the balance of iron and unavoidable impurities.

[0041] The production process of the low-yield-ratio high-strength thick plate is as follows:

[0042] According to the above composition design and preparation of smelting raw materials, after smelting and casting, a slab with a thickness of 80mm is formed;

[0043] The billet is heated to 1200°C, followed by two-stage rolling, the first-stage rolling temperature is 1114°C, rolling 4 passes, the thickness of the middle billet is 42mm, the second-stage rolling temperature is controlled at 926°C, and the final rolling temperature is 796 ℃, rolling 5 passes, plate thickness 20mm;

[0044] The above-mentioned rolled plate is controlled and cooled, the cooling rate after rolling is 10°C / s, the final cooling temperature is...

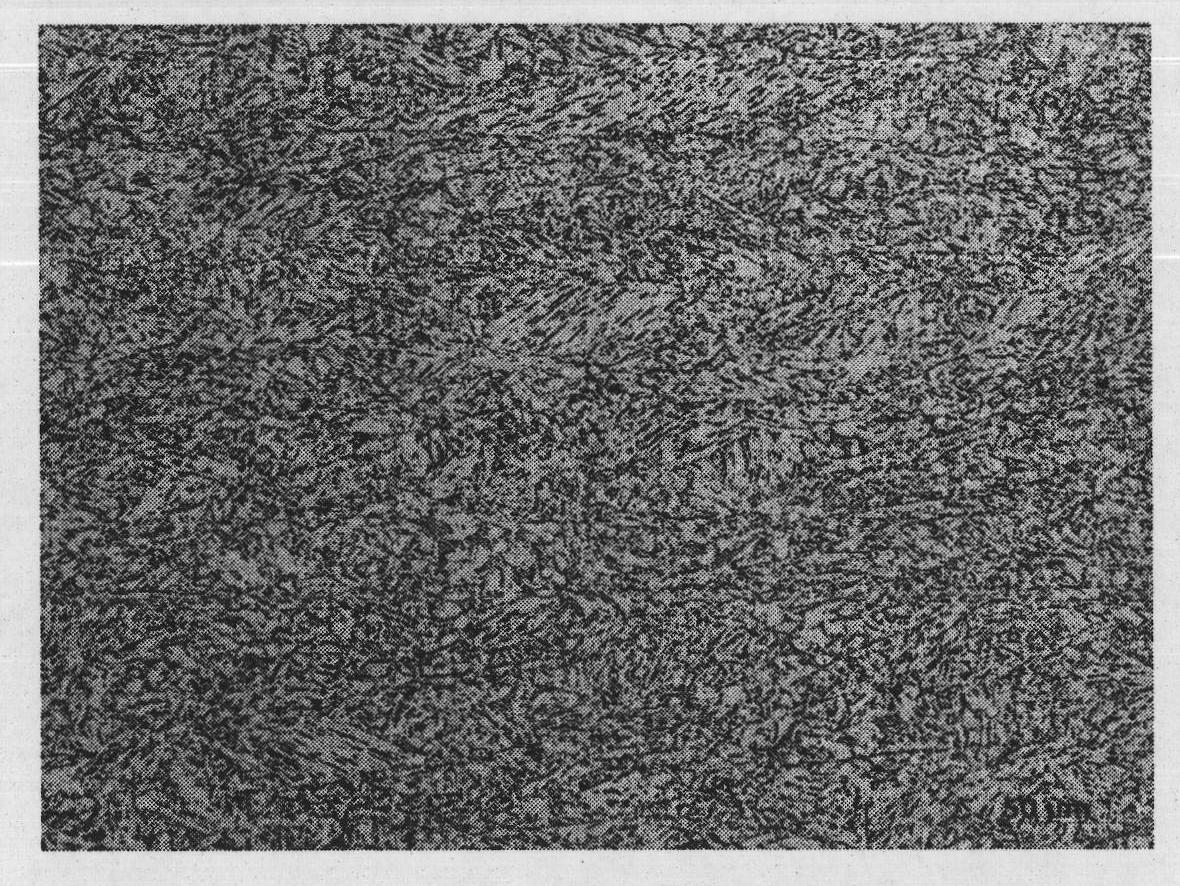

Embodiment 2

[0045] Example 2 The low-yield ratio high-strength thick plate of this example adopts the following composition design: C 0.08%, Si 0.25%, Mn 1.72%, Al 0.039%, Nb 0.058%, Ti 0.017%, Ni 0.32%, Cu 0.31%, Cr 0.25%, and the balance is iron and unavoidable impurities.

[0046] The production process of the low-yield-ratio high-strength thick plate is as follows:

[0047] According to the above composition design and preparation of smelting raw materials, after smelting and casting, a slab with a thickness of 80mm is formed;

[0048] The billet is heated to 1200°C, followed by two-stage rolling, the first-stage rolling temperature is 1136°C, rolling 4 passes, the thickness of the intermediate billet is 42mm, the second-stage rolling temperature is controlled at 923°C, and the final rolling temperature is controlled At 776°C, rolling 5 passes, plate thickness 20mm;

[0049] The above-mentioned rolled plate is controlled and cooled. After rolling, the cooling rate is 10°C / s, the fin...

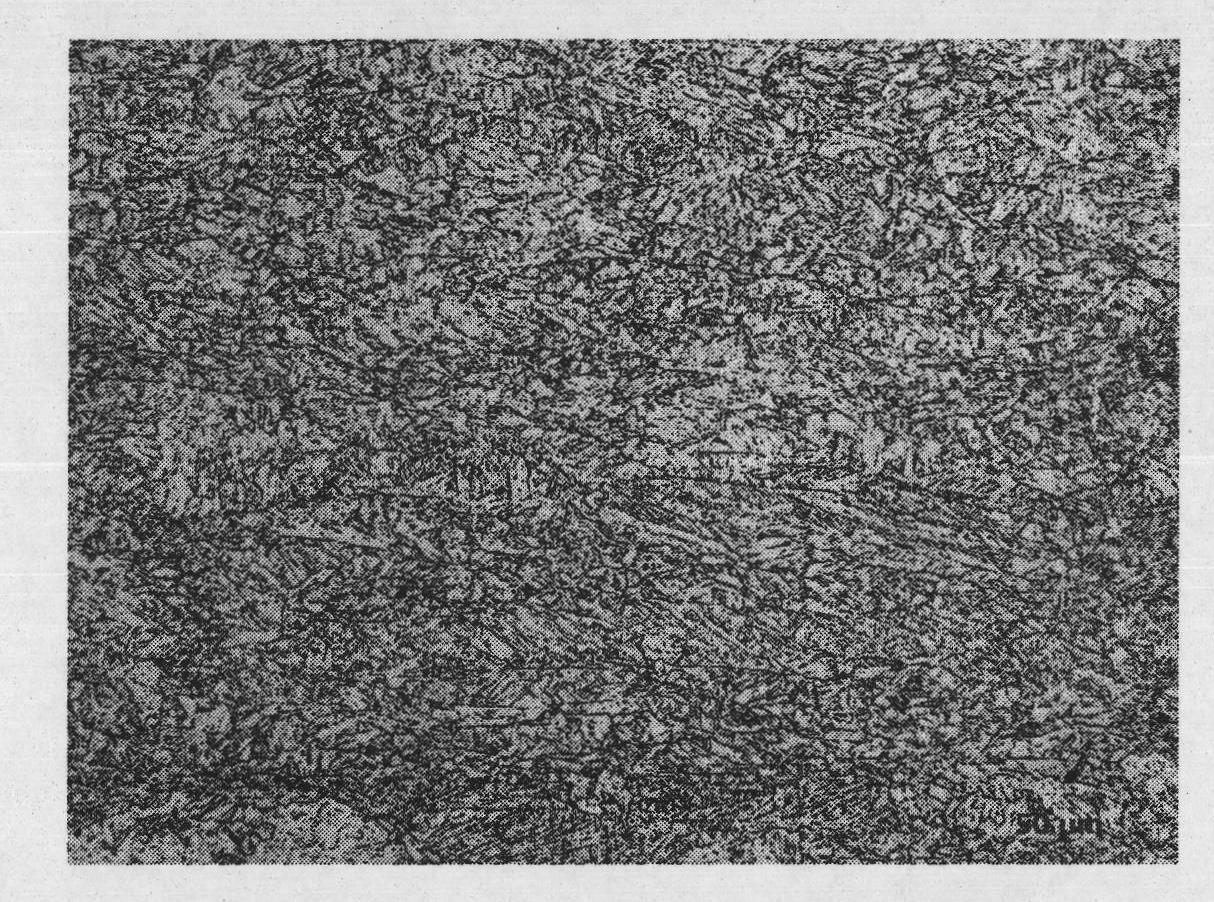

Embodiment 3

[0050] Example 3 The low-yield ratio high-strength thick plate of this example adopts the following composition design: C 0.07%, Si 0.20%, Mn 1.69%, Al 0.043%, Nb 0.065%, Ti 0.015%, Ni 0.37%, Cu 0.35%, Cr 0.17%, and the balance is iron and unavoidable impurities.

[0051] The production process of the low-yield-ratio high-strength thick plate is as follows:

[0052] According to the above composition design and preparation of smelting raw materials, after smelting and casting, a slab with a thickness of 80mm is formed;

[0053] The billet is heated to 1200°C, followed by two-stage rolling, the first-stage rolling temperature is 1122°C, rolled for 4 passes, the thickness of the intermediate billet is 42mm, the second-stage rolling temperature is controlled at 917°C, and the final rolling temperature is controlled At 806°C, rolling 5 passes, plate thickness 20mm;

[0054] Controlled cooling of the above-mentioned rolled plate, the cooling rate after rolling is 15°C / s, the fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com