Extraction device for arsenic in copper smelting waste residues

An extraction device and copper smelting technology, which is applied in the field of arsenic extraction device in copper smelting waste slag, can solve the problems of crushing waste slag that cannot be large particles, and achieve the effect of reducing the impact and improving the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

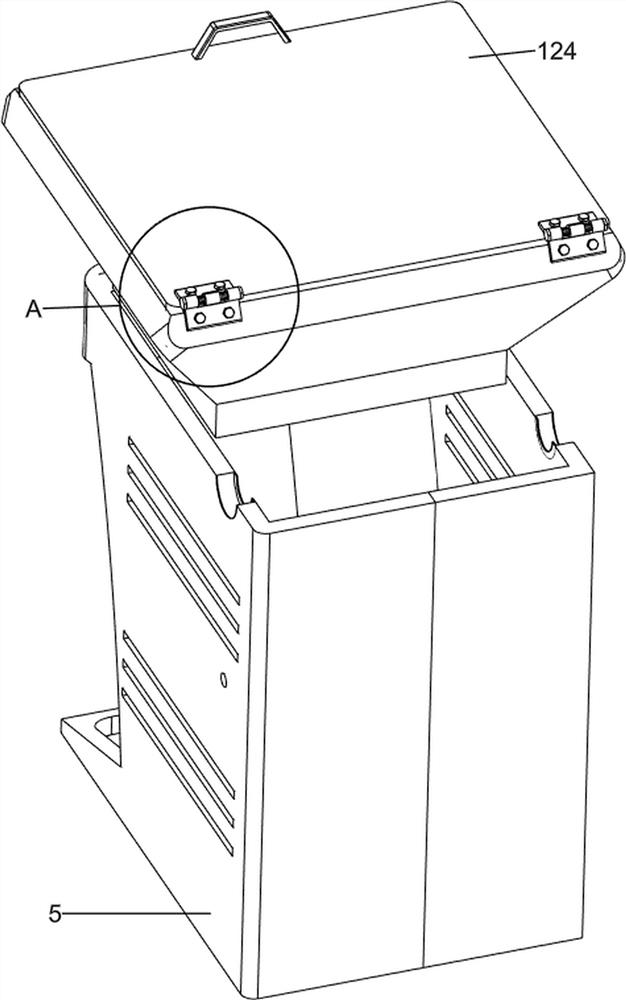

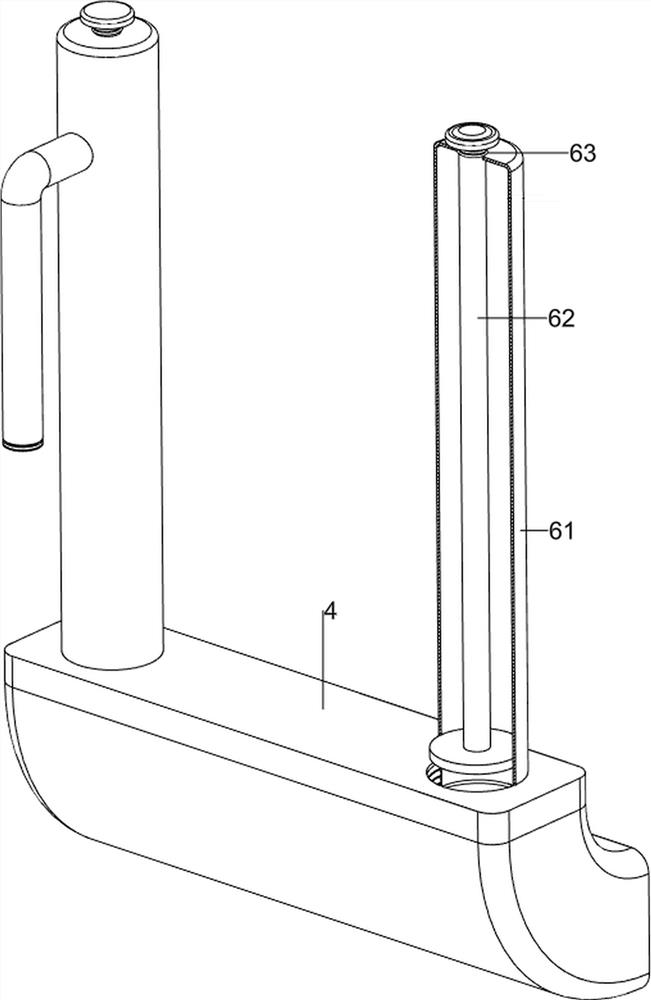

A device for extracting arsenic in copper smelting waste residue, such as Figure 1-6 As shown, it includes a placing box 1, a hot melting furnace 2, a material distribution box 3, a gas outlet frame 4, a material passing frame 5, a gas charging mechanism 6 and a blasting mechanism 7, and a hot melting furnace 2 is provided on the inner upper side of the placing box 1, The hot melting furnace 2 is resistant to high temperature, and can be loaded with waste residue for arsenic extraction. The upper side of the placing box 1 is provided with a distribution box 3, and the left side of the distribution box 3 is provided with an air outlet frame 4. The arsenic-containing smoke and dust generated in the extraction of arsenic can be extracted from The air outlet frame 4 is discharged. A material feeding frame 5 is arranged between the upper parts of the front and rear sides of the material distribution box 3. The front middle of the feeding frame 5 is rotatably connected with a turntab...

Embodiment 2

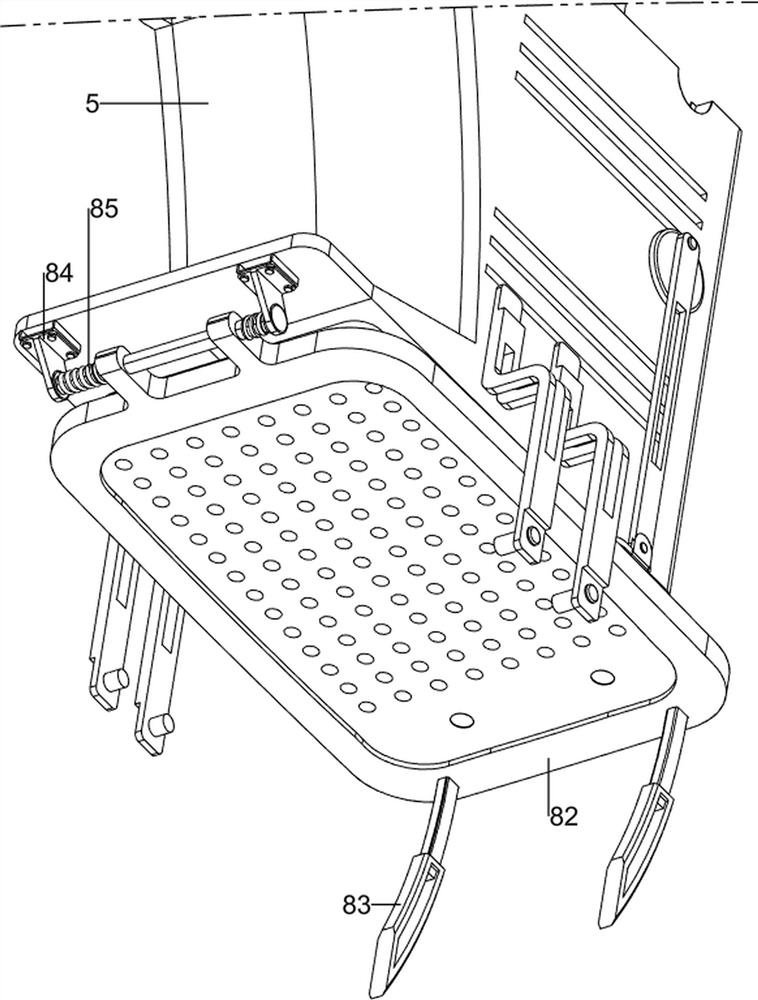

On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 7 and Figure 8 As shown, it also includes a thinning mechanism 8 for screening the waste residue. The thinning mechanism 8 includes a first connecting rod 81, a screening frame 82, a limit frame 83, a second fixing frame 84 and a first torsion spring 85, The turntable on the output shaft of the motor 72 is rotatably connected with the first connecting rod 81 , the turntable at the front of the feeding frame 5 is also rotatably connected with the first connecting rod 81 , and the left part of the lower side of the feeding frame 5 is provided with a second fixing frame 84. The middle part of the second fixing frame 84 is rotatably connected with the screening frame 82. The second fixing frame 84 has a fixed effect on the screening frame 82. The screening frame 82 can screen the waste residue dropped from the feeding frame 5, and the screening frame The front and rear sides of the upper right part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com