X70 pipeline rolling plate for microalloyed resistance weld pipe and production method of X70 pipeline rolling plate

A technology of micro-alloying and production methods, which is applied in the direction of metal rolling, etc., can solve the problems of increased manufacturing costs, achieve the effects of easy production process, excellent strength and toughness, and reduce the cost of alloy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above-mentioned embodiments are only to illustrate the technical concept and features of the present invention, rather than to limit the present invention. The purpose is to enable those skilled in the art to understand the content of the present invention and implement it accordingly. All equivalent changes or modifications made according to the spirit of the present invention shall fall within the protection scope of the present invention.

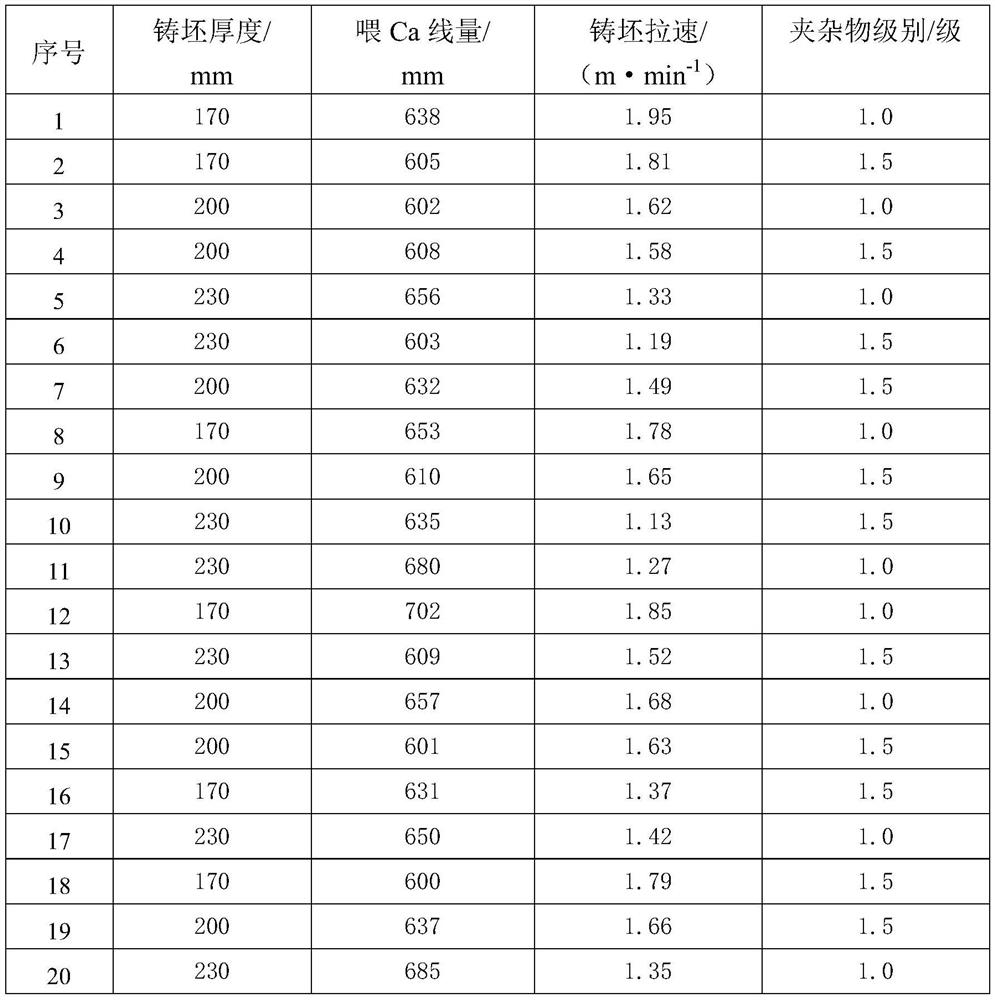

[0033] Table 1 lists the chemical composition of the steel in the example; Table 2 shows the smelting and continuous casting process parameters of the steel in the example; Table 3 lists the process execution of the steel in the example; Table 4 shows the mechanical properties of the steel in the example.

[0034] Chemical composition of table 1 embodiment steel, wt%

[0035] serial number C Si mn P S Nb Ti Mn / C Al / N Ceq Pcm 1 0.051 0.16 1.7 0.012 0.003 0.07 0.015 33 4.75 0.33 0.14 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com