Ferritic stainless steel for automobile exhaust emission system

A technology of emission system and automobile exhaust gas, applied in the field of ferritic stainless steel, can solve the problems of pouring interruption, increase of grinding cost and material loss, increase of steel-making cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

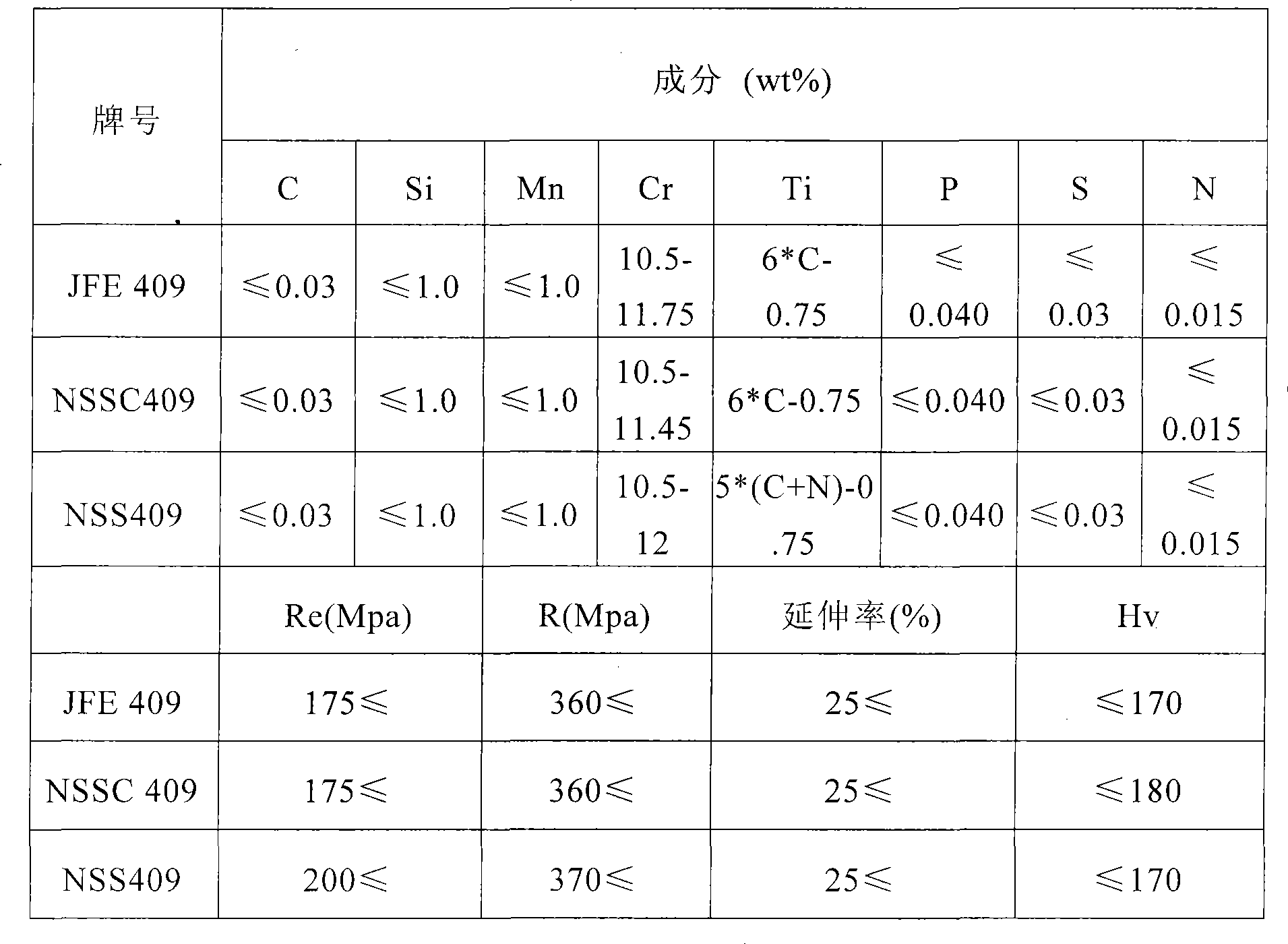

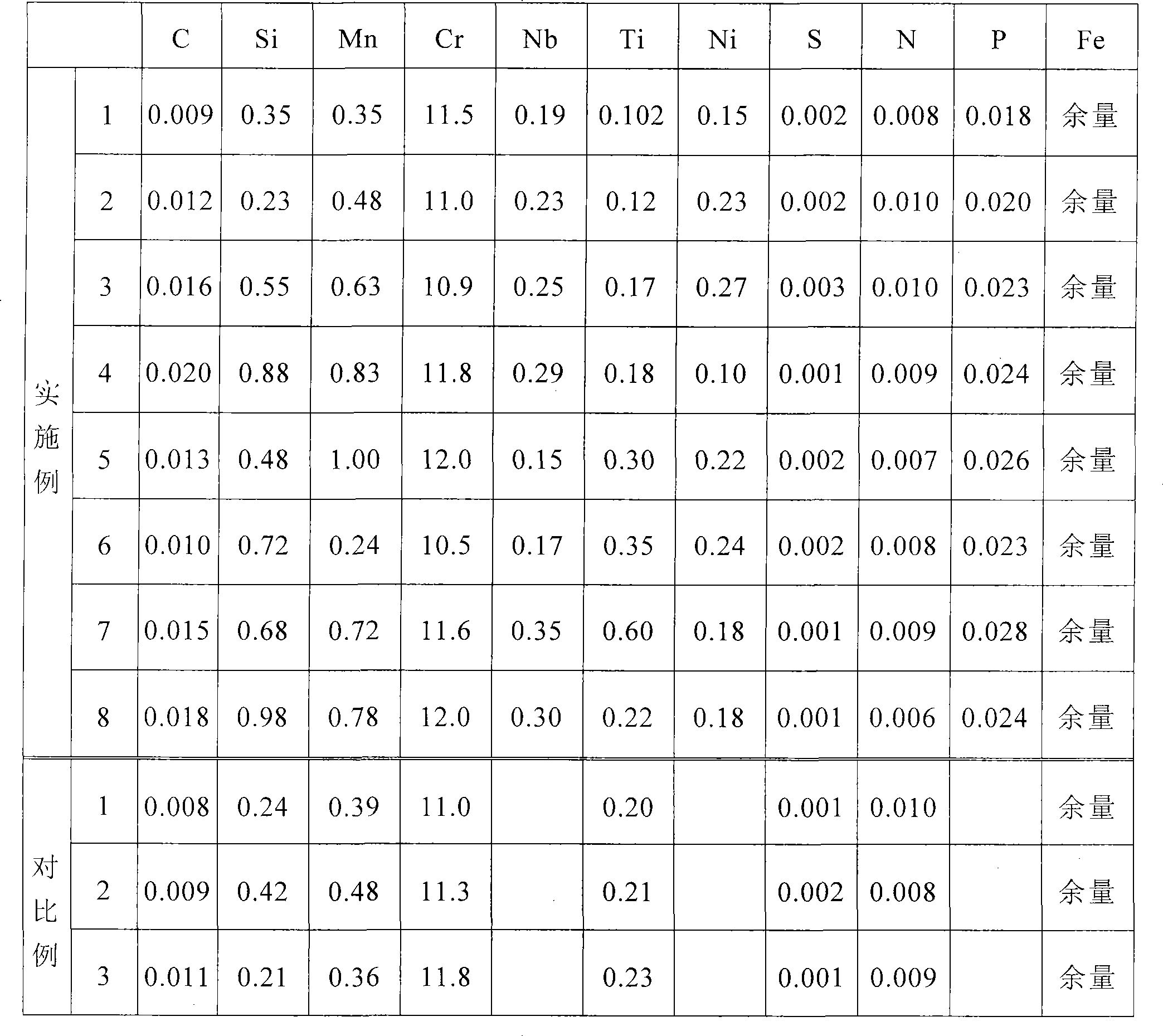

[0051] Table 3 shows the chemical composition of the experimental steel grades of the present invention.

[0052] Among them, Examples 1-8 are steel types of the present invention, and Comparative Examples 1-3 are steels for ferritic stainless steel exhaust systems commonly used in automobiles at present.

[0053] Table 3 The chemical composition of the steel of the present invention and the existing similar ferritic stainless steel, wt%

[0054]

[0055] Table 4 is a comparison of the mechanical properties and intergranular corrosion properties of the steel of the present invention and the steel of the comparative example. Among them, the mechanical properties test yield strength, tensile strength, elongation, hardness and formability (r value). Corrosion Performance Determination of intergranular corrosion resistance and uniform corrosion resistance, resistance to intergranular corrosion with Cu-CuSO 4 -16%H 2 SO 4 After soaking in the boiling solution for 24 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com