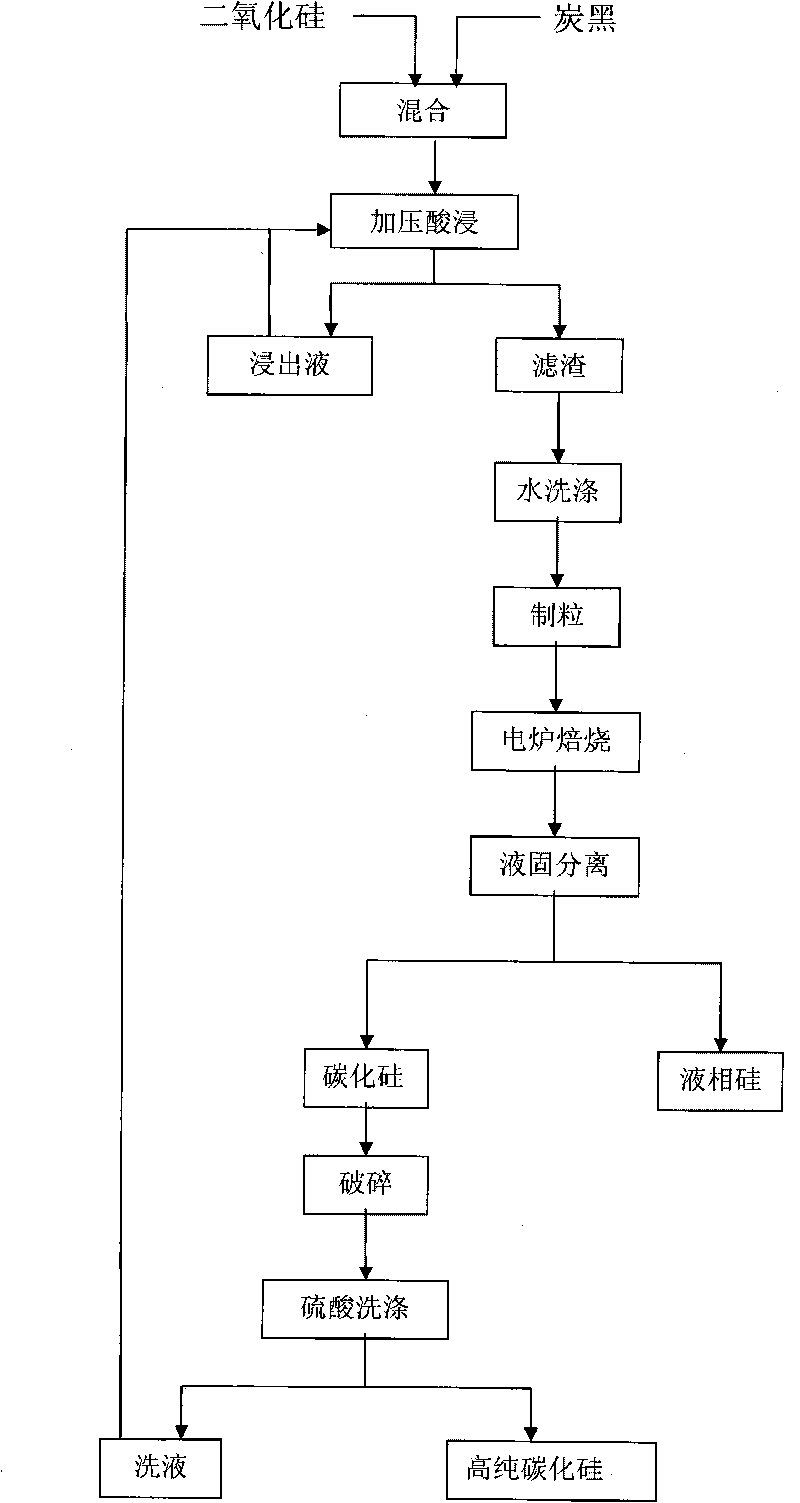

Production technology of high purity silicon carbide

A high-purity silicon carbide and production process technology, applied in the chemical and metallurgical fields, can solve the problems of no production capacity, high market price and high technical requirements, and achieve the effects of low production cost, easy industrial production and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: the impurity content that grinds is that 0.05% silicon dioxide and the carbon black of impurity content<0.09% pass through 0.0043mm sieve respectively, after mixing with mass ratio 1: 1.2, adjust with the sulfuric acid solution that concentration is 60g / L Slurry, the liquid-solid ratio is 4:1, and then placed in a pressurized autoclave, the pressure inside the autoclave is controlled to 1.2MPa, the temperature is 200 ° C, stirred for 1 hour, the slag liquid after sulfuric acid leaching is filtered to obtain mixed slag, washed with water until neutral ; Granulate the mixed slag with a particle size of 3 cm, put it into an electric furnace for roasting at a temperature of 1600 degrees, break the obtained silicon carbide, wash with a sulfuric acid solution with a concentration of 80 g / L for 4 hours, filter, and dry High-purity silicon carbide with an impurity content of less than <0.001% is obtained.

Embodiment 2

[0010] Embodiment 2: The impurity content that will grind is that 0.05% silicon dioxide and the carbon black of impurity content<0.09% pass through 0.0043mm sieve respectively, after mixing with mass ratio 1: 1.2, adjust with the sulfuric acid solution that concentration is 60g / L Slurry, the liquid-solid ratio is 4:1, and then placed in a pressurized autoclave, the pressure inside the autoclave is controlled to 1.2MPa, the temperature is 200 ° C, stirred for 1 hour, the slag liquid after sulfuric acid leaching is filtered to obtain mixed slag, washed with water until neutral ; Granulate the mixed slag with a particle size of about 3 cm, put it into an electric furnace for roasting at a temperature of 1600 degrees, break the obtained silicon carbide, wash with a sulfuric acid solution with a concentration of 80 g / L for 4 hours, filter, and dry Dry to obtain high-purity silicon carbide with an impurity content of less than <0.001%.

Embodiment 3

[0011] Embodiment 3: the impurity content of grinding is 0.03% silicon dioxide and the carbon black of impurity content<0.05% pass through 0.0043mm sieve respectively, after mixing with mass ratio 1: 1.2, adjust with the sulfuric acid solution that concentration is 60g / L Slurry, the liquid-solid ratio is 4:1, and then placed in a pressurized autoclave, the pressure inside the autoclave is controlled to 1.2MPa, the temperature is 200°C, and stirred for 2 hours, the slag liquid after sulfuric acid leaching is filtered to obtain mixed slag, which is washed with water until neutral ; Granulate the mixed slag with a particle size of 3 cm, put it into an electric furnace for roasting at a temperature of 1700 degrees, break the obtained silicon carbide, wash with a sulfuric acid solution with a concentration of 100 g / L for 5 hours, filter, and dry High-purity silicon carbide with an impurity content of less than <0.001% is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com