Carbon blowing technique for electric furnace smelting

A technology of electric furnace smelting and carbon spraying, which is applied in the direction of electric furnace, process efficiency improvement, furnace, etc., can solve the problems such as difficult to accurately and effectively control the amount of carbon increase, uneven distribution, poor effect of carbon increase, etc., and shorten the smelting time , Scrap steel recovery rate improvement, the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

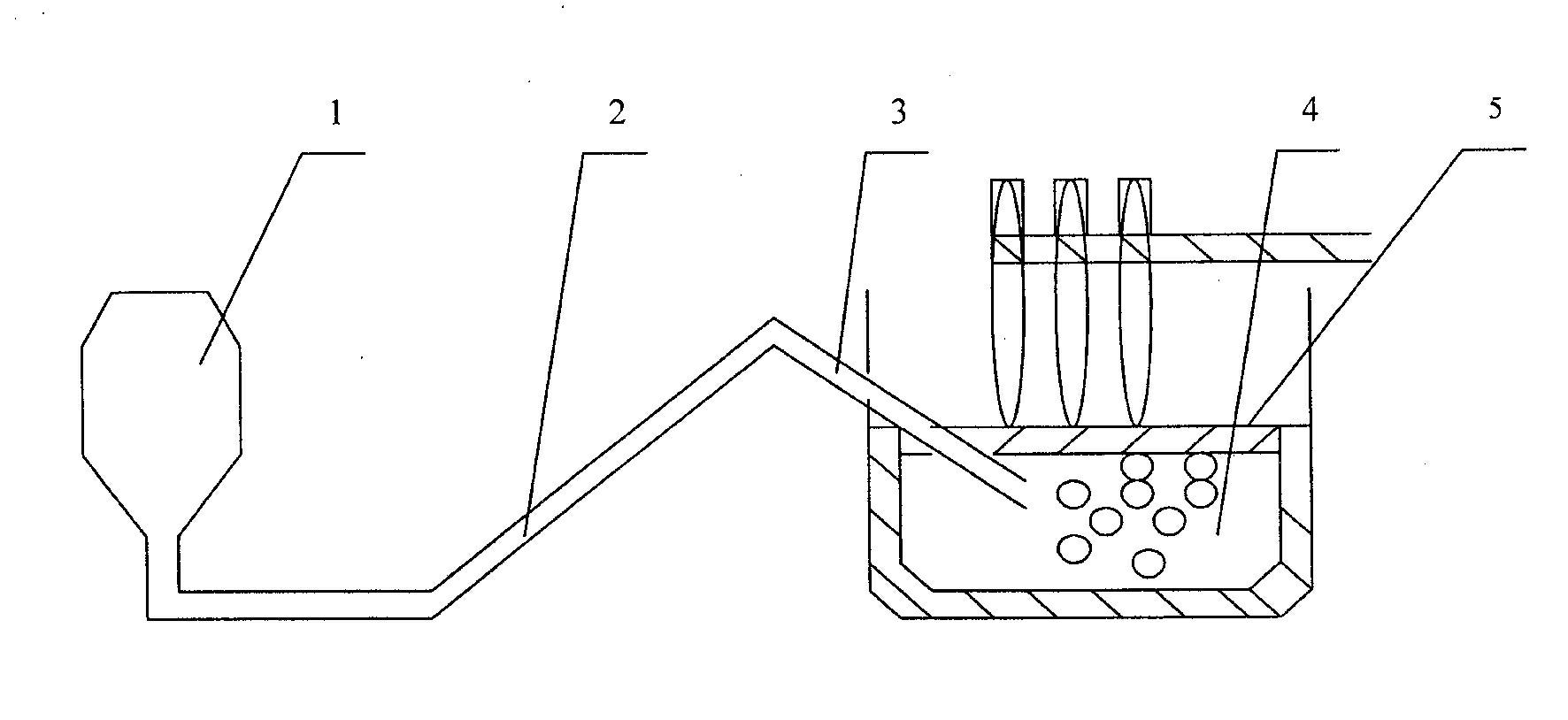

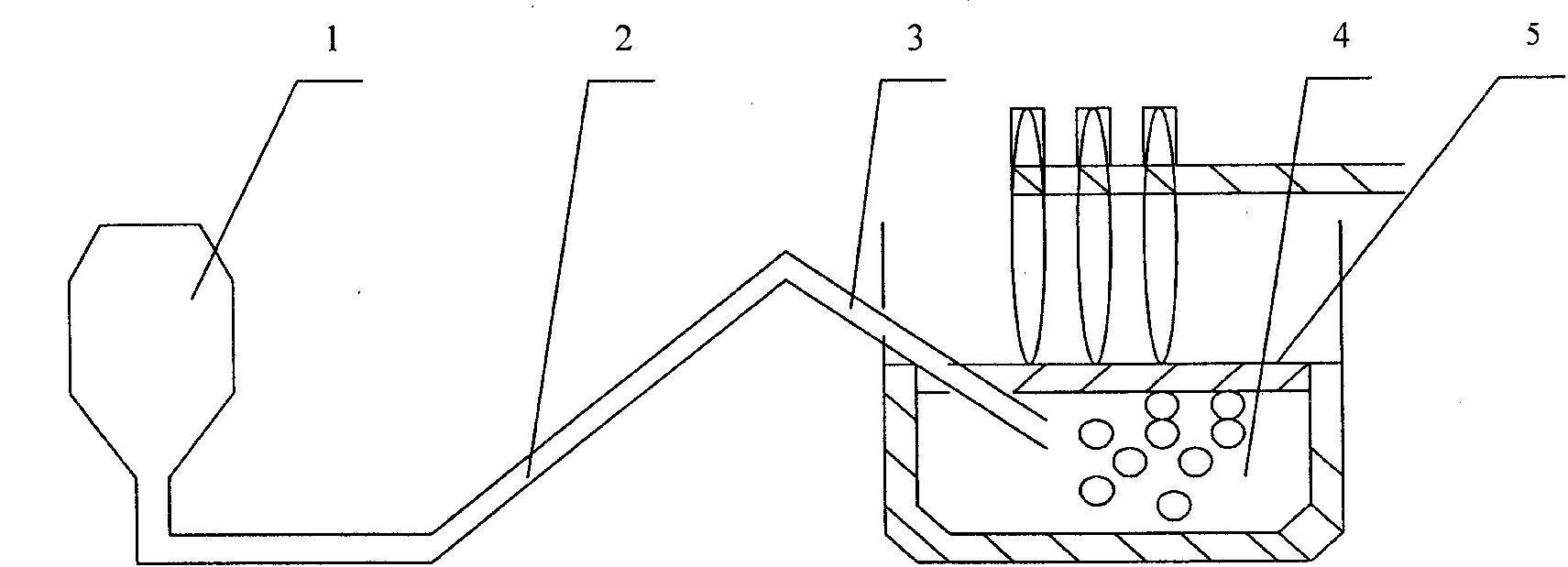

[0020] Embodiment 1 (adopt multiple injection method)

[0021] The present invention comprises the following steps:

[0022] a. Filling coke powder

[0023] First screen the coke powder: particle size φ≤3mm, moisture content≤3%, sulfur content≤2.5%, and then put 0.8 tons of coke powder after screening into the gunning machine 1. The gunning machine 1 is a purchased part, the model is PB-Y1.2.

[0024] b. Adjust the compressed air pressure

[0025] Adjust the pressure of the gunning machine 1 and the pressure of the self-consumable carbon spray gun 3 to 0.2 MPa to 0.3 MPa;

[0026] c. Open the toner feed valve of the gunning machine;

[0027] d. Insert the self-consumable carbon spray gun 3 through the slag layer 5 into the molten steel in the electric arc furnace molten pool 4;

[0028] e. Electric arc furnace smelting:

[0029] ⑴For the first time, add 12 tons of scrap steel to the electric furnace, send electricity, blow oxygen to melt, and form a molten pool when the ...

Embodiment 2

[0034] Embodiment 2 (adopting one-shot injection method)

[0035] The steps of this embodiment are the same as those of Embodiment 1, the difference is: step e electric arc furnace smelting,

[0036] ⑴ For the first time, add 13 tons of scrap steel to the electric furnace, send electricity and blow oxygen to melt, so that the furnace material is melted to form a molten pool with a carbon content of >0.30%.

[0037] (2) For the second time, add 11 tons of steel scrap to the electric furnace, send electricity and blow oxygen to melt, so that the furnace material is melted to form a molten pool with a carbon content of >0.30%.

[0038] (3) For the third time, add 10.5 tons of steel scrap to the electric furnace, send electricity, blow oxygen to melt, when the temperature of the molten pool rises, all the scrap steel is melted, and when the temperature is >1550°C, take a sample ① (see Table 2), and analyze the furnace through a spectrum analyzer The chemical composition of the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com