Magnetic steel heat-insulating shield and manufacturing method thereof

A technology of protective cover and magnetic steel, which is applied to the parts of the instrument, shielding, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

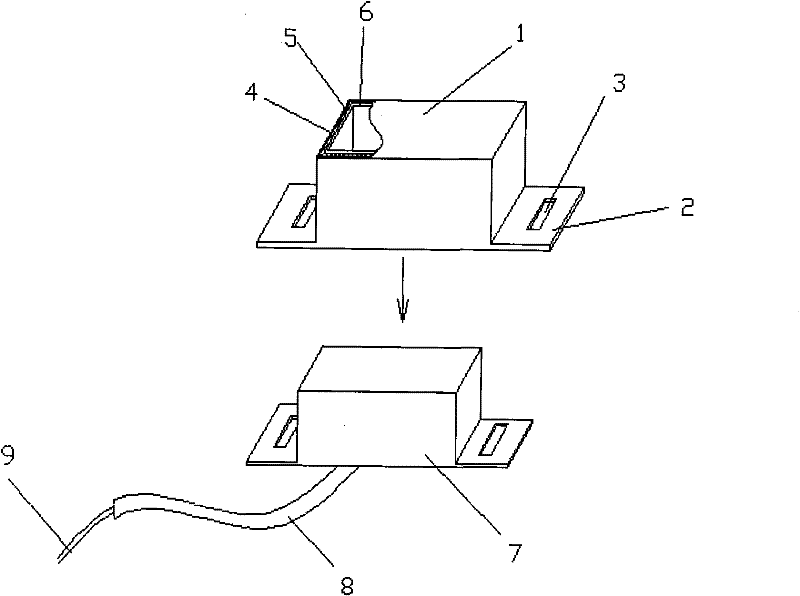

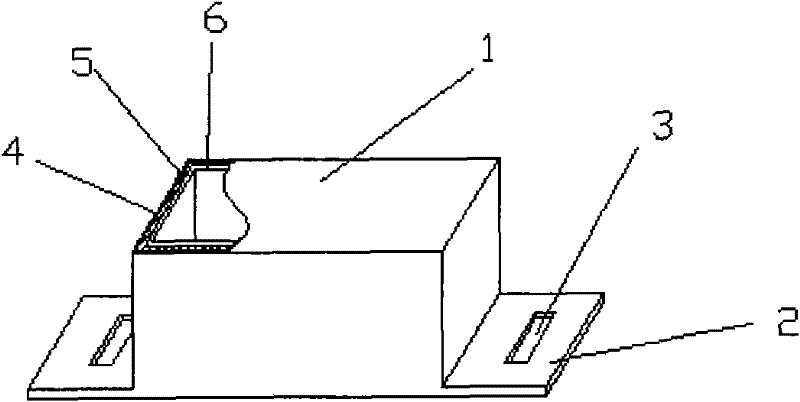

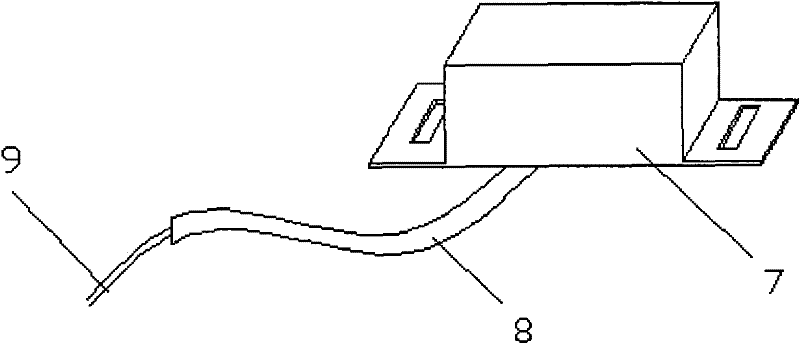

[0019] Embodiment 1: according to the magnetic steel volume and outline mechanic, the mold of the magnetic steel heat-insulating protective cover is placed on the outer layer of the abrasive tool with an asbestos cover, and the three materials of resin, talcum powder and chopped yarn are mixed in a certain ratio (3: 2 : 1) Evenly apply 3-5mm on the surface of asbestos, dry naturally or in an oven, and finally evenly coat 1-2mm of aviation heat insulating paint on the outermost layer. When in use, use the magnetic steel heat insulation cover to cover the magnetic steel, and use the fixing bolts and fixing accessories to install the magnetic steel heat insulation cover with the magnetic steel on the inner side of the rail specified in the iron ladle tracking system. The communication cable of the pipe passes under the rail to connect with the communication equipment in the side box.

Embodiment 2

[0020] Embodiment 2: As a modified example of the magnetic steel heat shield of the embodiment, the mold of the heat shield can be processed according to the volume and contour of the communication product antenna in the iron bag tracking system, and the antenna magnetic steel heat shield can be produced. When in use, put the antenna heat shield from one end of the antenna and push it to the other end of the antenna, cover the antenna completely, and fix the antenna on the rail sleeper with bolts through the antenna fixing frame and fixing accessories, and fix the bolts at the same time Play the role of fixing the antenna and its antenna heat shield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com