A Method for Setting and Online Optimization of Process Parameters in Production Process of Continuous Annealing Unit

A technology of production process and process parameters, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as large energy consumption, difficult continuous annealing units, and inability to fully utilize the production capacity of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

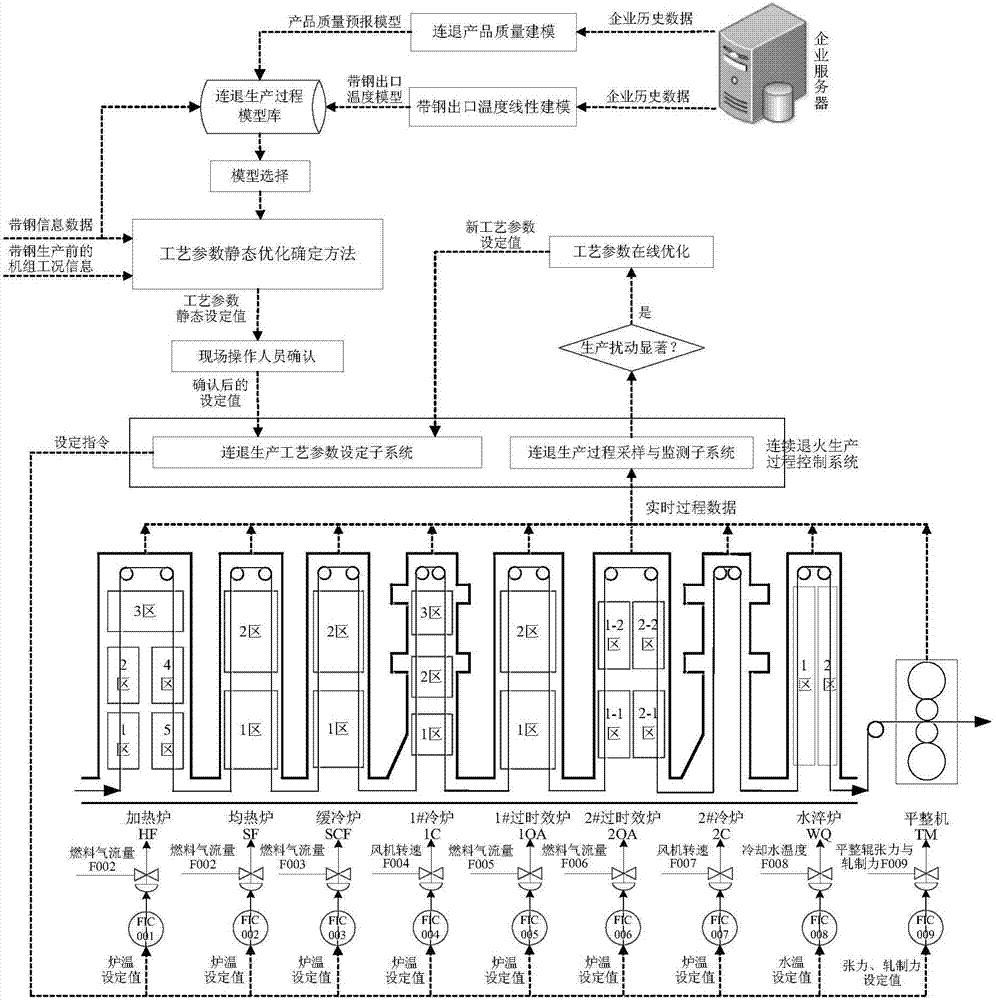

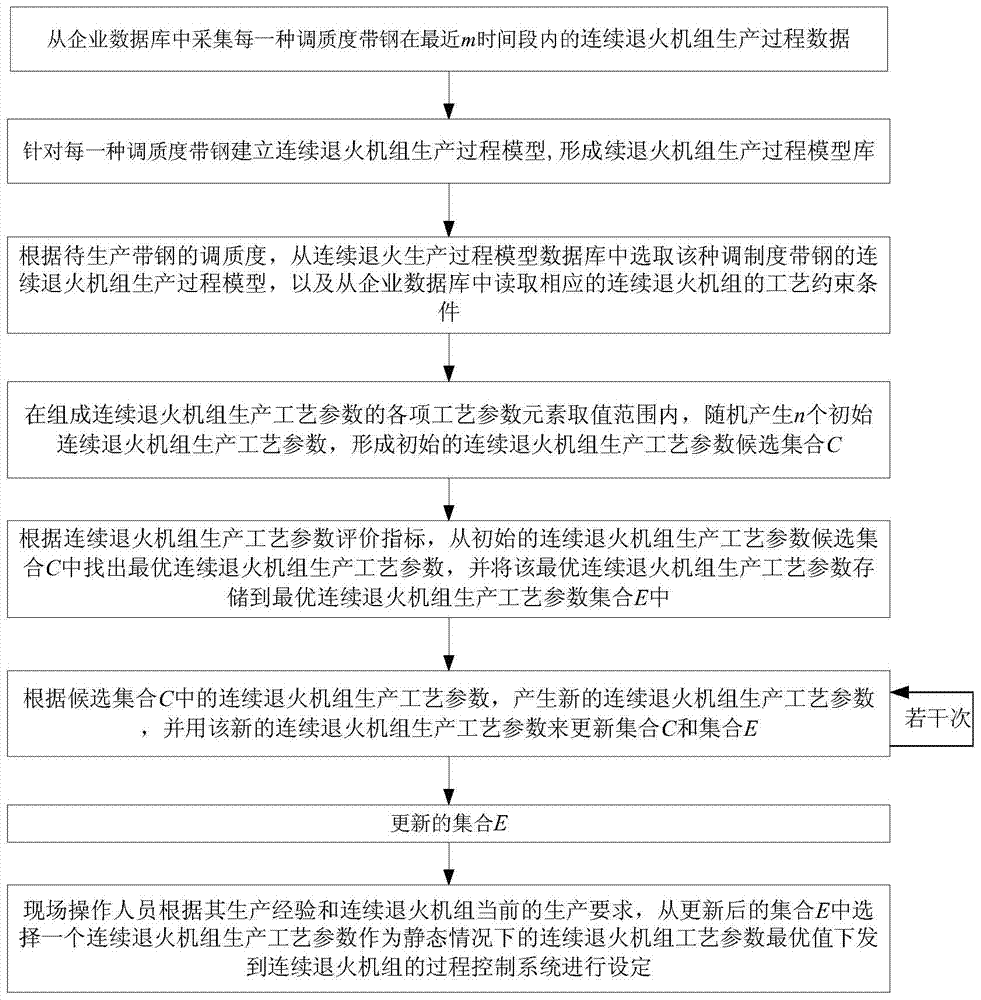

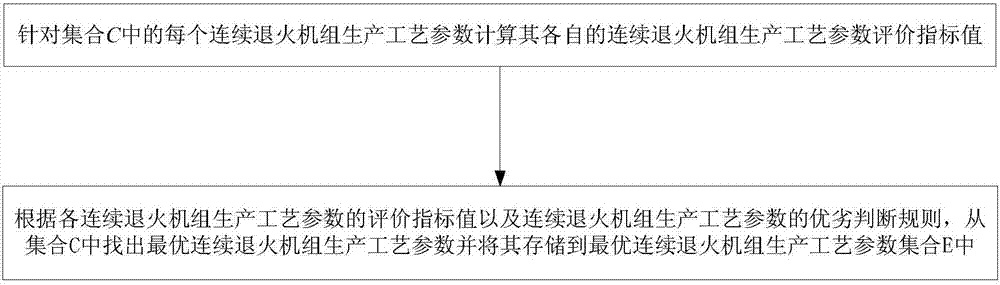

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0057] The continuous annealing unit is located in the cold rolling plant of the iron and steel enterprise. After the hot-rolled strip steel arrives at the cold rolling plant, it is first pickled to remove the oxide scale on the surface of the strip steel, and then undergoes five-stand cold rolling to become a cold-rolled thin strip with a thickness meeting the contract requirements. steel. Due to the large internal stress formed inside the strip steel due to cold deformation during the cold rolling process, which will affect the quality and mechanical properties of the strip steel, the cold rolled strip steel must be annealed and processed in the continuous annealing unit according to the specified process curve After heating, soaking, slow cooling, rapid cooling, overaging, quenching, leveling and other operations, the internal stress is elim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com