Roll management system and method for bar rolling in iron and steel enterprises

A management system and roll technology, applied in the computer field, can solve the problems of high work intensity, lack of grinding records or explanations for scrapping reasons, difficult statistics, etc., and achieve the effect of reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

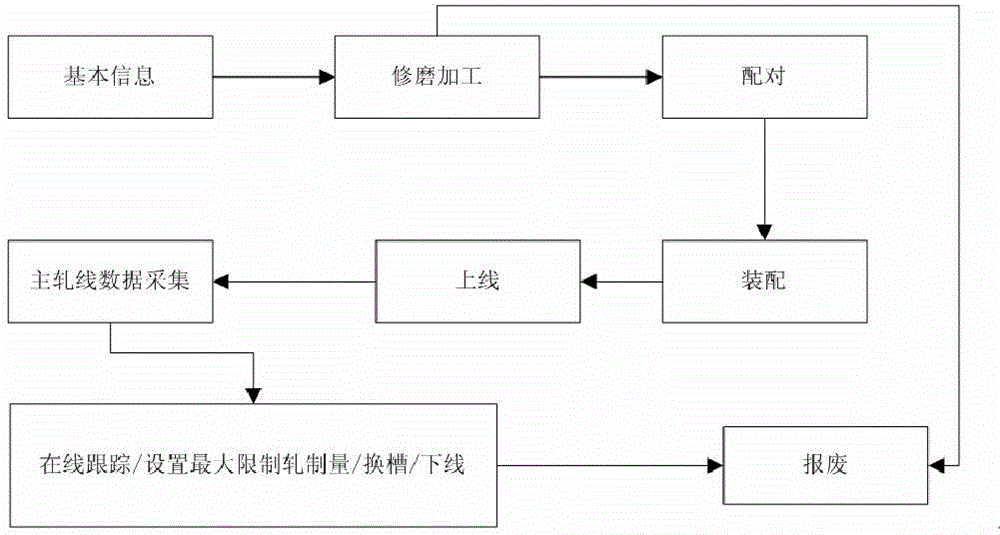

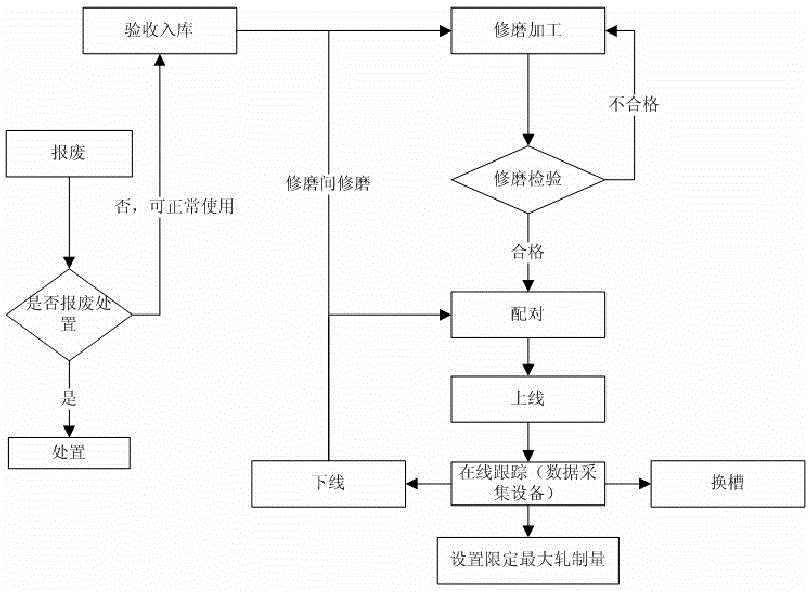

[0028] The iron and steel enterprise bar rolling roll management system of the present invention includes a basic information module, a processing module, a pairing module, an assembly module, an online module, a main rolling line data acquisition module, a tracking module, and a scrapping module, wherein:

[0029] Basic information module: used to number according to the factory number of the roll and the actual production, and record the factory parameters and information;

[0030] Processing module: used to record the working parameters after roll grinding, preset assembly frame and information;

[0031] Matching module: used for roll type matching, recording pairing informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com