Method for preparing Sialon material inside blast furnace

A technology of al2o3-sic and blast furnace, which is applied in the field of refractory material production for blast furnace ironmaking, can solve the problems of large one-time investment, high cost, high cost, etc., achieve great economic and social benefits, save production costs, and prolong blast furnace The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

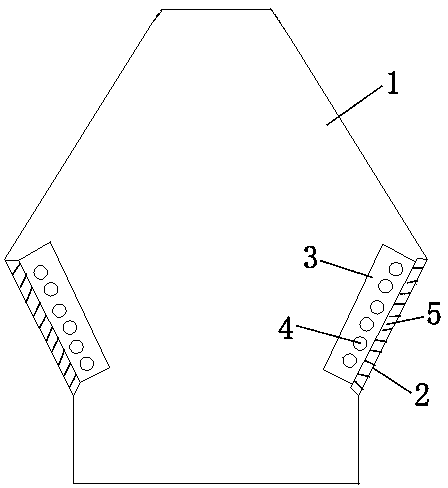

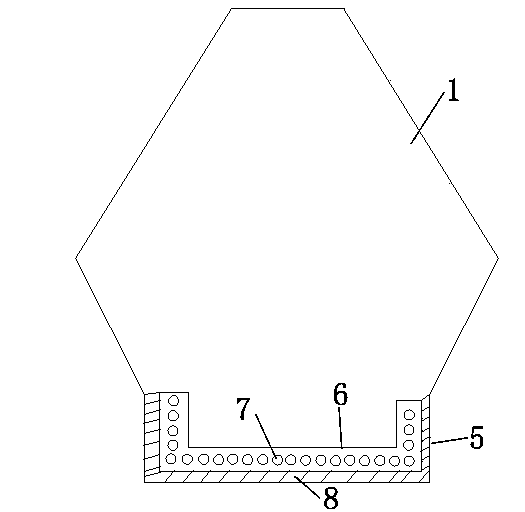

Image

Examples

Embodiment 1

[0027] The construction material used in the construction body of this embodiment consists of the following materials in parts by weight: Al 2 o 3 50 parts of materials (the mass percentage of low-carbon brown corundum is 90%, and the rest is α-Al 2 o 3 Ultrafine powder; Fe in low carbon brown corundum 2 o 3 The mass percentage is 0.4-0.6%, TiO 2 1-3% by mass), 10 parts of SiC, 8 parts of silicon-aluminum alloy powder (the mass ratio of Al:Si is 1:3), 2 parts of C powder, and 5 parts of water;

[0028] The pressing material used is made up of the following materials in parts by weight: Al 2 o 3 50 parts of materials (the mass percentage of low-carbon brown corundum is 90%, and the rest is α-Al 2 o 3 Ultrafine powder; Fe in low carbon brown corundum 2 o 3 The mass percentage is 0.4-0.6%, TiO2 The mass percentage is 1-3%), 10 parts of SiC, 8 parts of silicon aluminum alloy powder (the mass ratio of Al to Si is 1:3.5), 2 parts of C powder, 0.1 part of rare earth oxide (...

Embodiment 2

[0034] The construction material used in the construction body of this embodiment consists of the following parts by weight: Al 2 o 3 60 parts of materials (the mass of low-carbon brown corundum accounted for Al 2 o 3 95% of the material, the rest is α-Al 2 o 3 Ultrafine powder; Fe in low carbon brown corundum 2 o 3 The mass percentage is 0.4-0.6%, TiO 2 The mass percentage is 1-3%), 30 parts of SiC, 12 parts of silicon aluminum alloy powder (the mass ratio of Al:Si is 1:4), 3 parts of C powder, 2 parts of rare earth oxide (from xenotime), 5 parts clay, 4 parts water.

[0035] The pressing material used is composed of the following parts by weight: Al 2 o 3 60 parts of materials (the mass of low-carbon brown corundum accounted for Al 2 o 3 95% of the material, the rest is α-Al 2 o 3 Ultrafine powder; Fe in low carbon brown corundum 2 o 3 The mass percentage is 0.4-0.6%, TiO 2 The mass percentage is 1-3%), 30 parts of SiC, 12 parts of silicon aluminum alloy powd...

Embodiment 3

[0043] The construction material used in the construction body of this embodiment consists of the following parts by weight: Al 2 o 3 55 parts of materials (the mass percentage of low-carbon brown corundum is 93%, and the rest is white corundum powder; Fe in low-carbon brown corundum 2 o 3 The mass percentage is 0.4-0.7%, TiO 2 The mass percentage is 1-3%), 20 parts of SiC, 10 parts of silicon-aluminum alloy powder (the mass ratio of Al:Si is 1:3.5), 1 part of rare earth oxide (from bastnaesite), and 5 parts of water.

[0044] The pressing material used is composed of the following parts by weight: Al 2 o 3 55 parts of materials (the mass percentage of low-carbon brown corundum is 93%, the rest is white corundum powder, Fe in low-carbon brown corundum 2 o 3 The mass percentage is 0.4-0.7%, TiO 2 The mass percentage is 1-3%), 20 parts of SiC, 10 parts of silicon-aluminum alloy powder (the mass ratio of Al:Si is 1:3.8), and the particle size of the pressed material is ≤3m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com