Journal bearing and thrust pad assembly

a thrust pad and bearing technology, applied in the direction of couplings, manufacturing tools, gear boxes, etc., can solve the problems of premature replacement of prematurely worn bearings, accelerated localized wear of roller elements and bearing races, and equipment shut down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

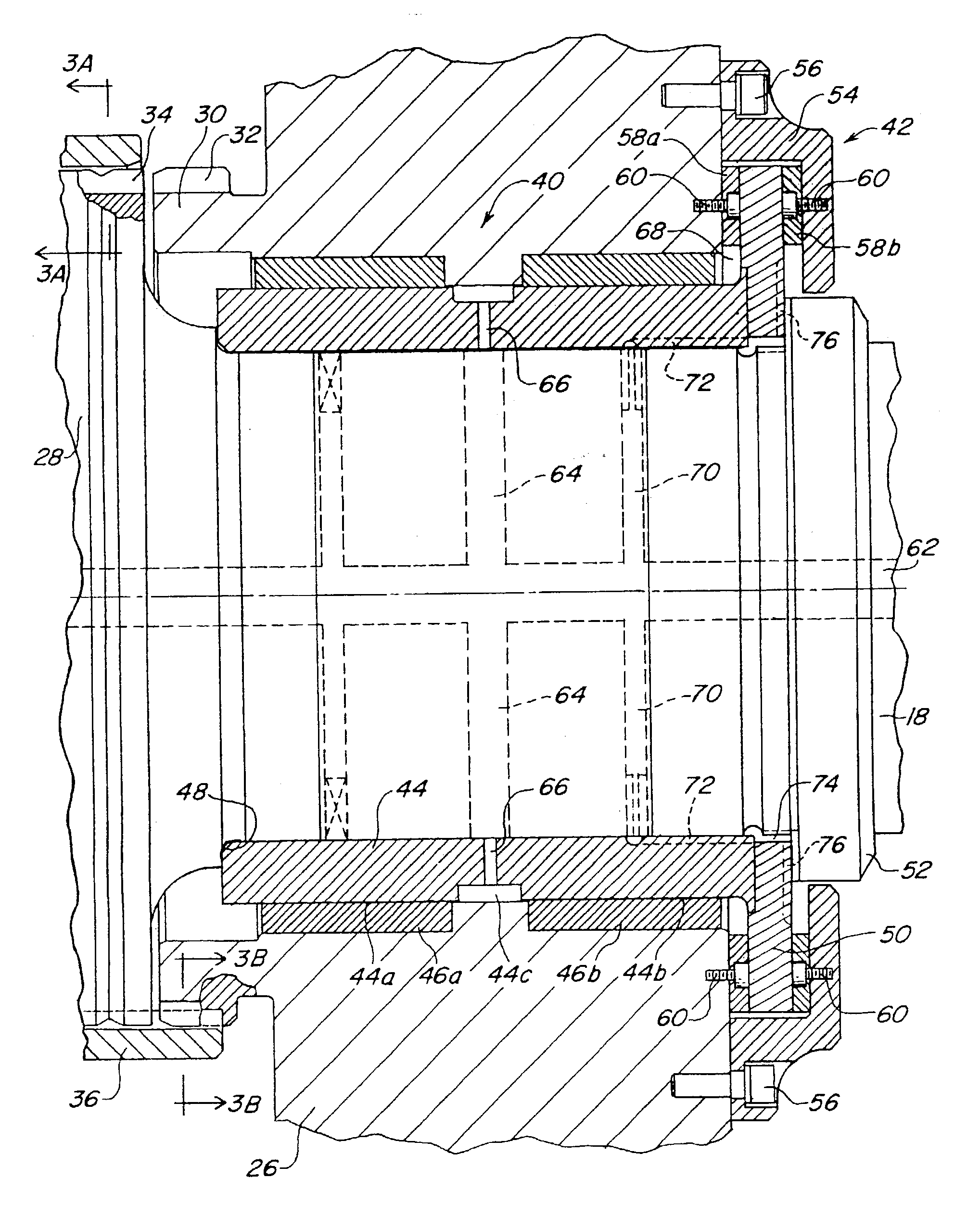

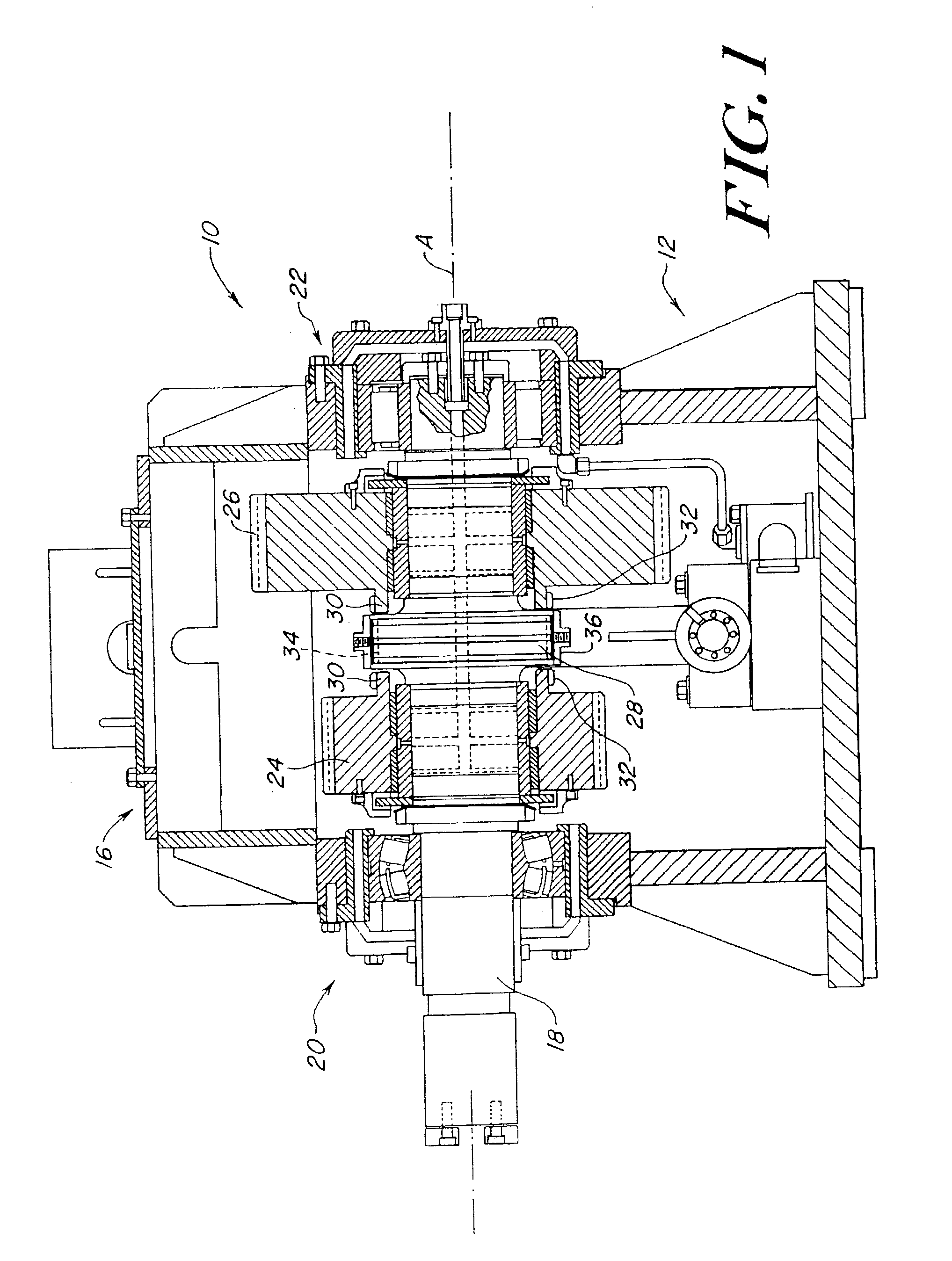

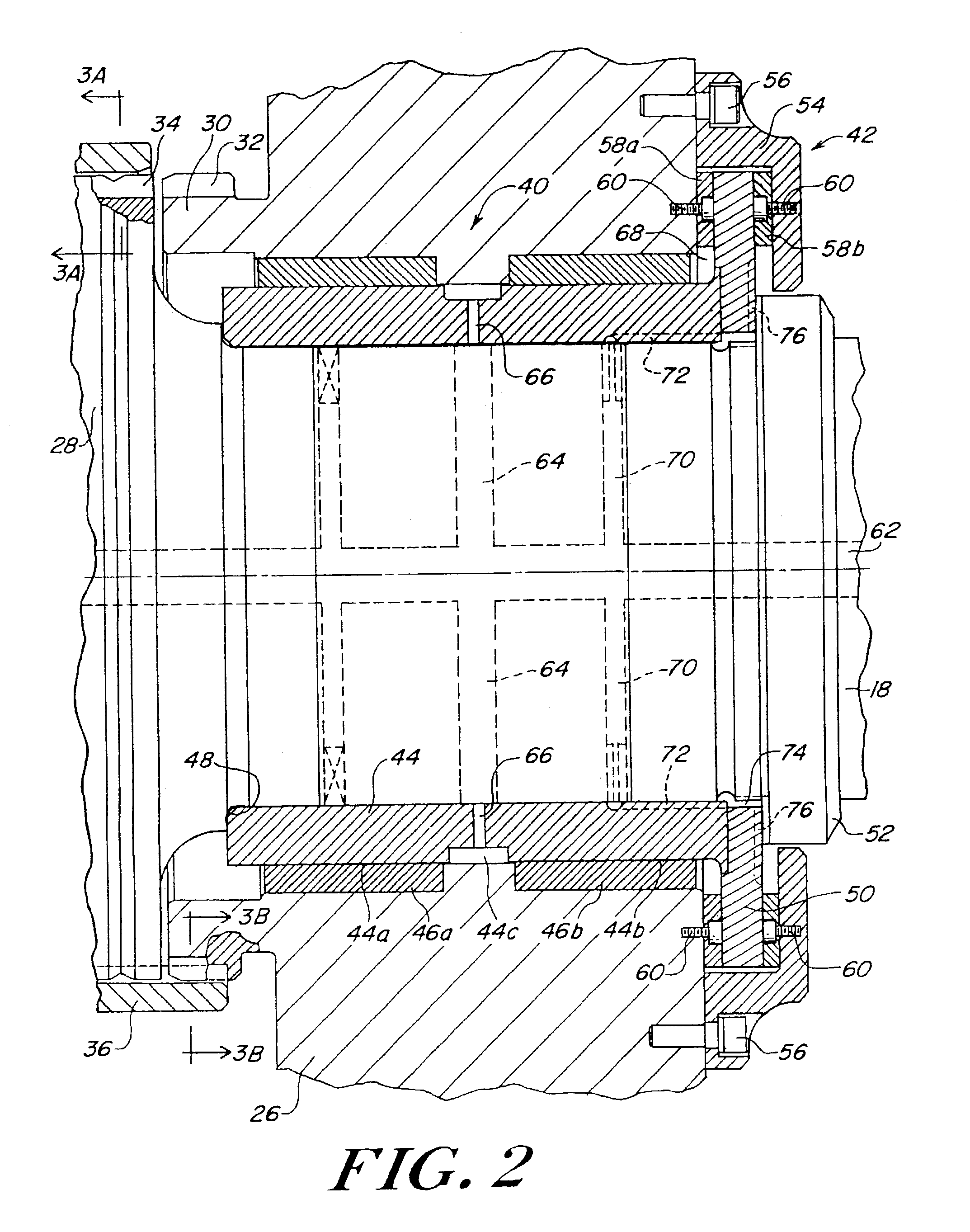

[0016]With reference initially to FIGS. 1, 2, 3A and 3B, a rolling mill gear box is shown at 10. The gear box includes a housing having a base section 12 and cover 16. A shaft 18 is mounted in the housing between bearings 20, 22 for rotation about an axis “A”. One end of the shaft protrudes from the housing for connection to a mill drive (not shown).

[0017]Gears 24, 26 are carried on the shaft on opposite sides of an enlarged diameter shaft collar 28. The gears have different diameters and numbers of teeth, and are thus capable of meshing with other mating gears in the gear box (not shown) to accommodate different drive ratios.

[0018]The gears 24, 26 are each provided with clutch collars 30 having teeth 32 which may be rotatably aligned with external splines 34 on the shaft collar 28. A sleeve 36 internally splined as at 37 is mounted on the shaft collar 28. Sleeve 36 is axially shiftable between a neutral position as shown in FIG. 1 and the upper portion of FIG. 2 and FIG. 3A, and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| driving forces | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com