Alternating-current direct-drive servo device for main transmission and two-roller radial spacing adjustment

A technology of AC direct drive and servo device, which is applied to the driving device of metal rolling mill, metal rolling, metal rolling, etc. It can solve the problems of low workpiece surface quality, large rolling forming force, and mold wear, and achieve Improve product surface quality, reduce mold wear, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

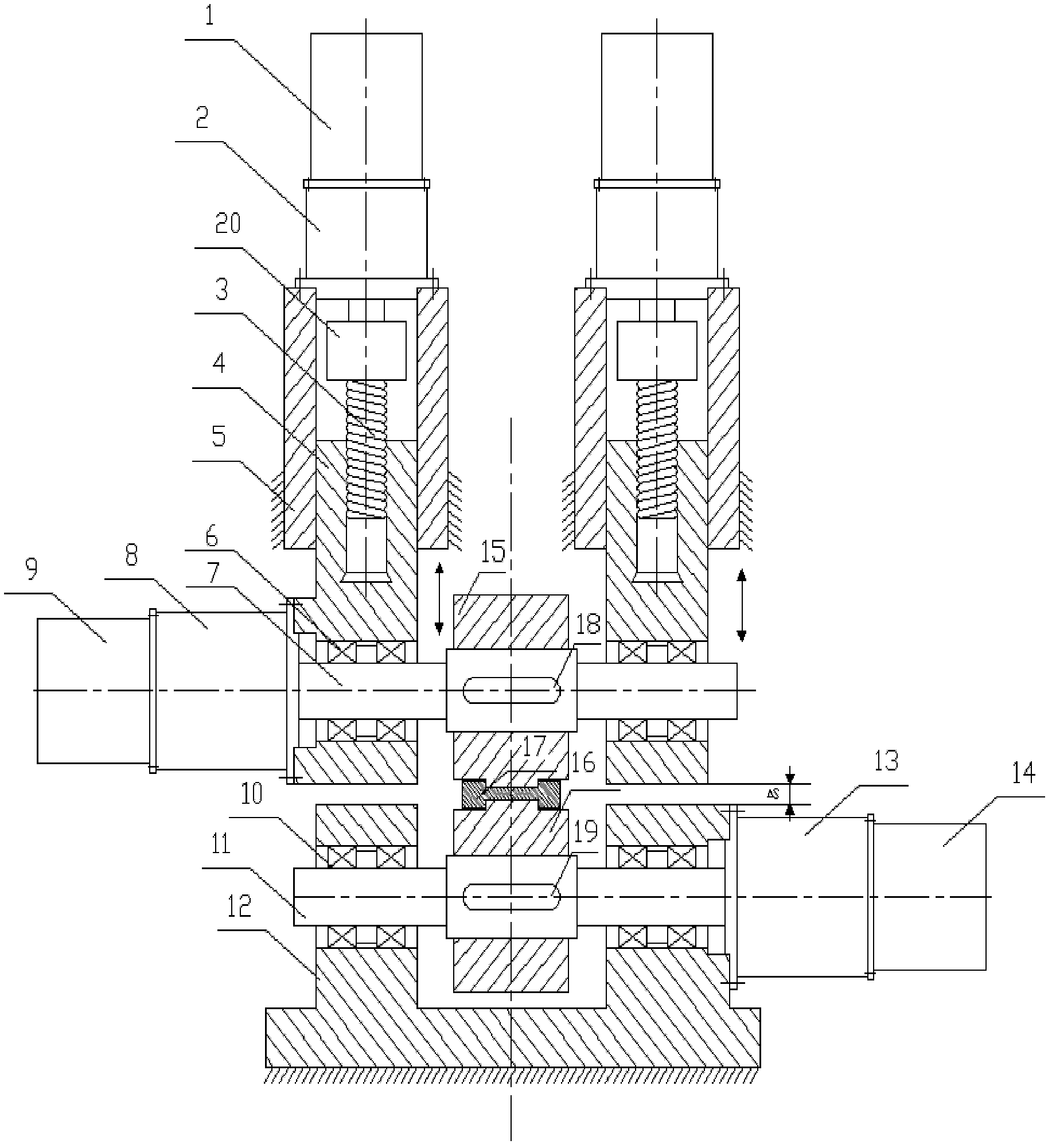

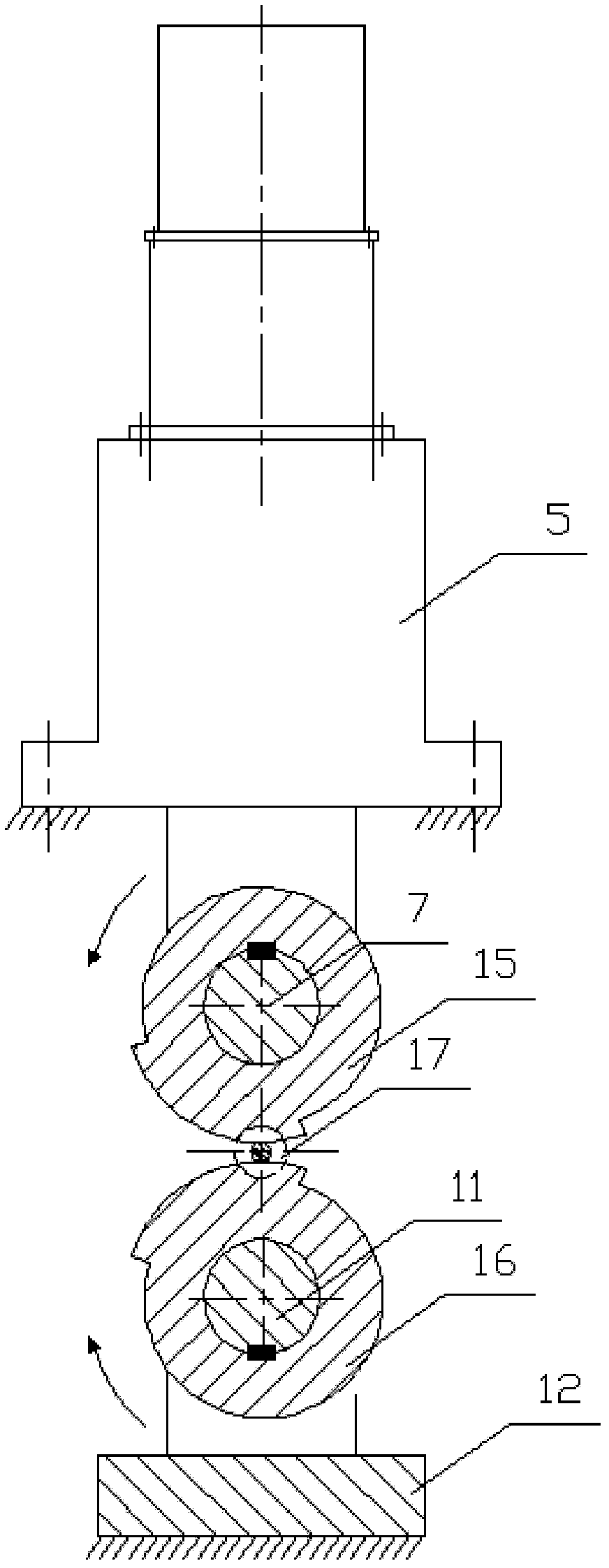

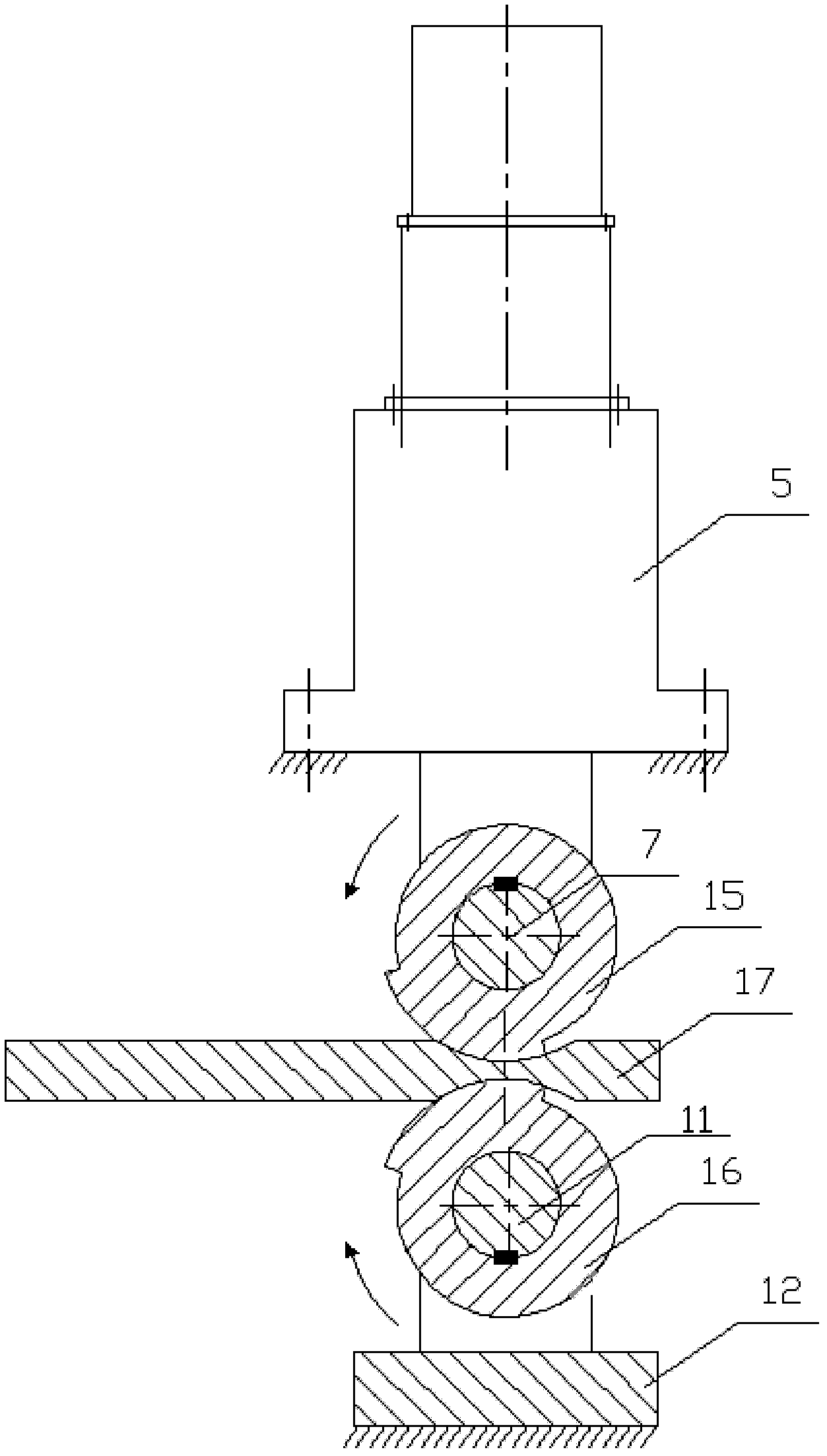

[0017] refer to figure 1 , an AC direct-drive servo device for adjusting the radial distance between the main drive and two rollers, the radial distance adjustment of the rollers is composed of two sets of completely symmetrical radial adjustment mechanisms on the left and right, the radial adjustment mechanism includes a first AC servo motor 1, The first AC servo motor 1 is connected to the input end of the first reducer 2, the output end of the first reducer 2 is connected to the input end of the vibrator 20, the first reducer 2 is fixed on the frame 5 by bolts, and the exciter The output end of the vibrator 20 is connected with the lead screw 3, and the vibrator 20 can generate low-frequency vibrations with a frequency of 5-30 Hz. The nut 4 is mounted on the lead screw 3 and cooperates with the lead screw 3, and through the self-rotation of the lead screw 3 The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com