Combined drive for flur-or six-high rolling mill and operating method for the same

The technology of four-high rolling mill and six-high rolling mill is applied in the driving device of metal rolling mill, metal rolling mill stand, metal rolling stand, etc., which can solve the problems of infeasibility and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

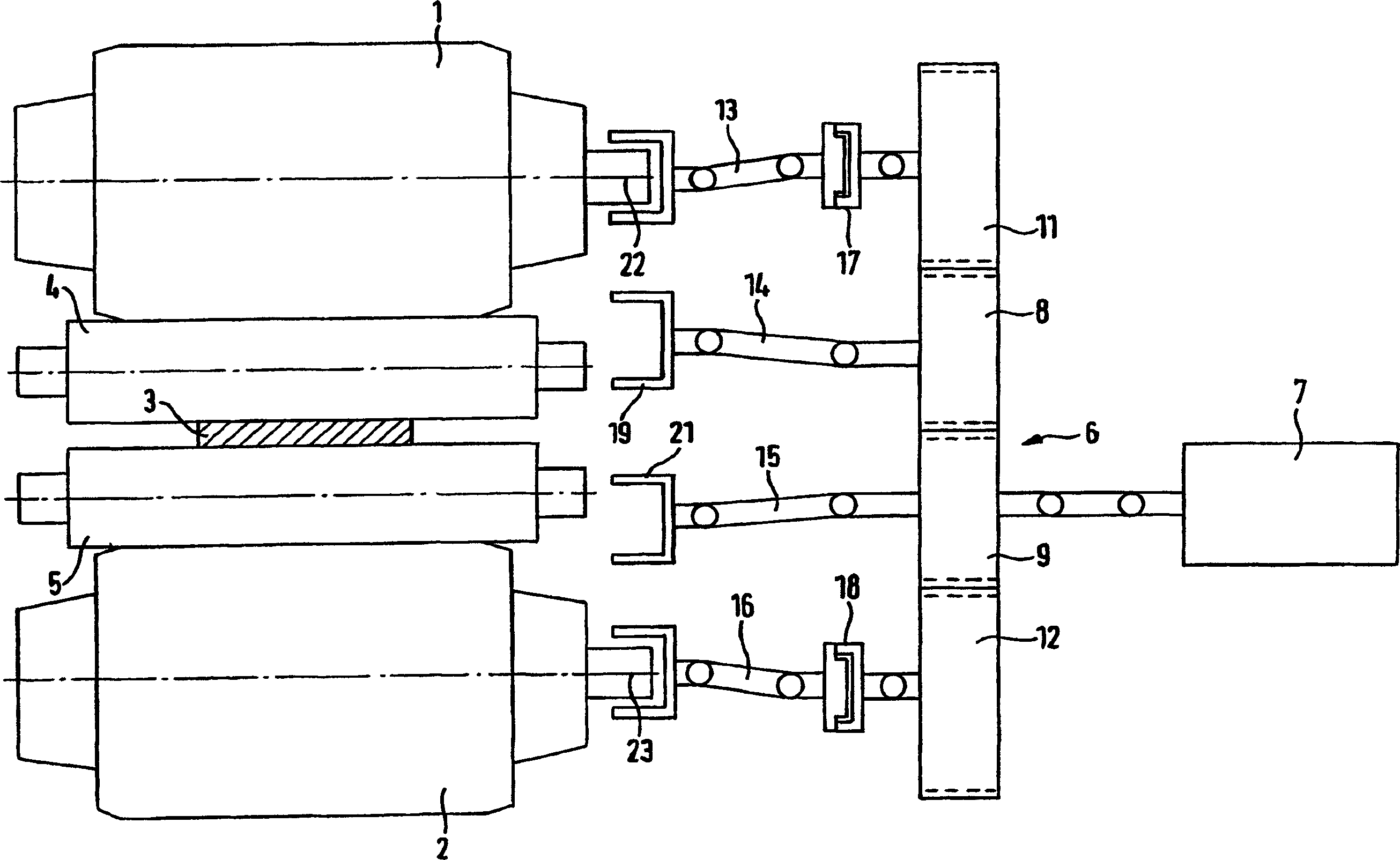

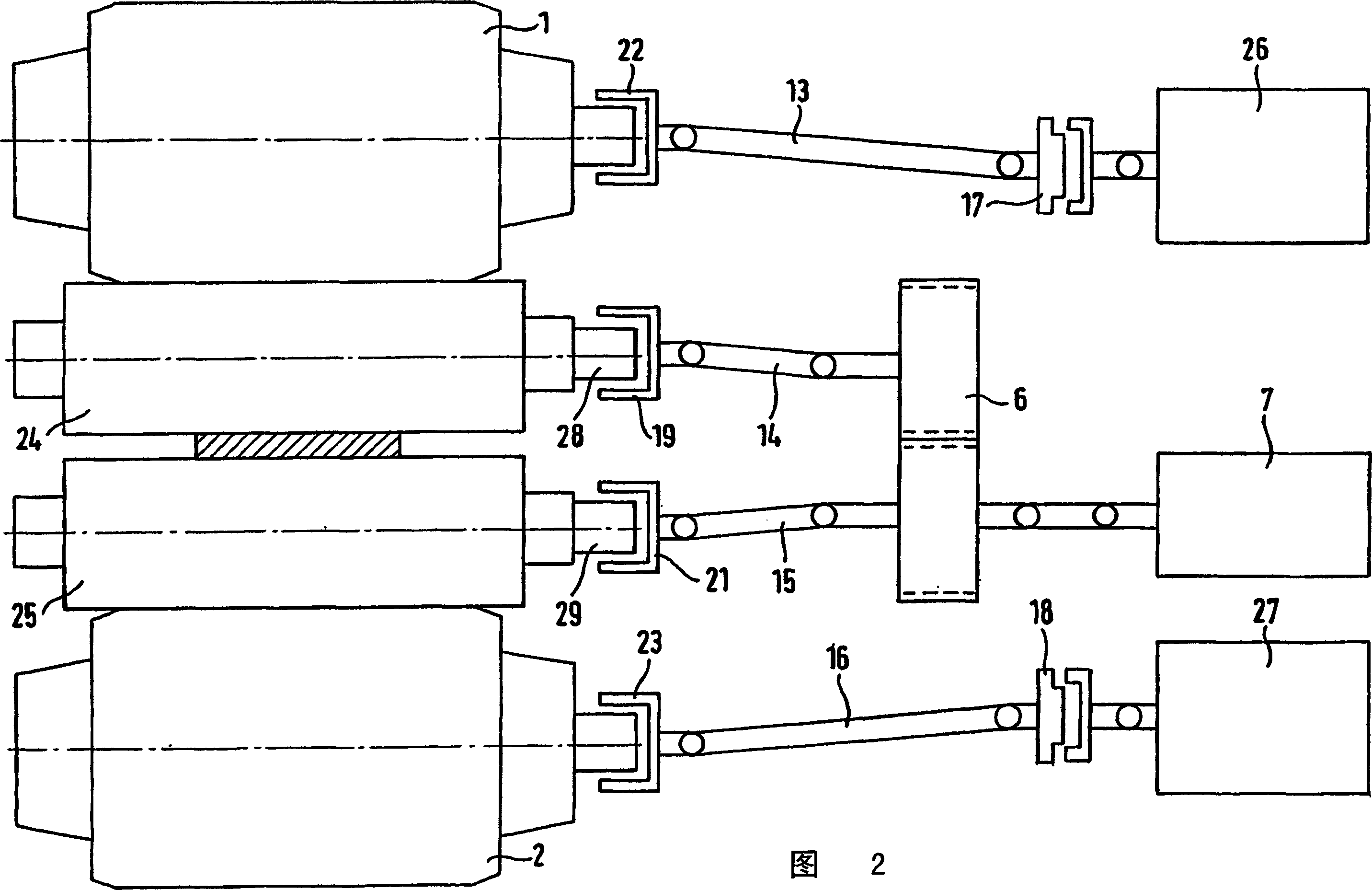

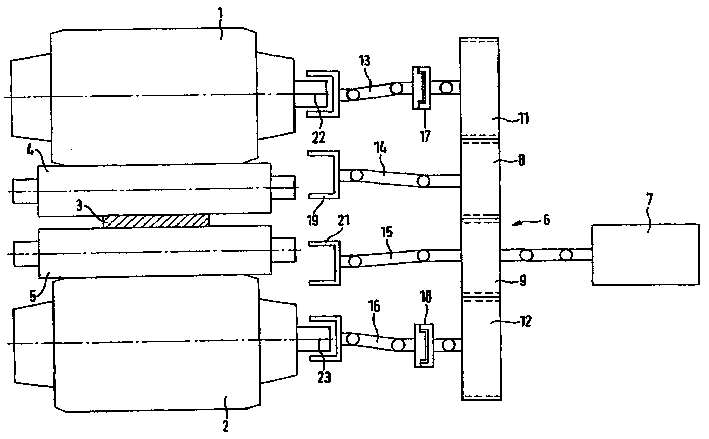

[0022] exist figure 1 , schematically shows back-up rolls 1, 2 of a four-high rolling mill, between which thin work rolls 4, 5 for a thinner rolling stock 3 are arranged.

[0023] A drive motor 7 equipped with a herringbone gear 6 is used to drive the rolls 1 , 2 , 4 , 5 . The herringbone gear transmission 6 includes two central work roll transmission gears 8 , 9 and one upper back-up roll transmission gear and one lower back-up roll transmission gear 11 , 12 .

[0024] The back-up rolls 1, 2 and the working rolls 4, 5 are respectively assigned transmission shafts 13, 14, 15, 16, and these transmission shafts are connected to the motor 7 through a herringbone gear transmission 6. The transmission shafts 13 , 16 assigned to the support rollers 1 , 2 each have an actuating clutch 17 , 18 which interrupts the force transmission path between the support rollers 1 , 2 and the electric motor 7 in the disengaged state.

[0025] because figure 1 The fine work rolls 4, 5 shown are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com