Magnetically actuated roller head

a technology of magnetic actuators and roller heads, which is applied in the direction of propulsion systems, metal-working machine components, manufacturing tools, etc., can solve the problems of increasing the cost, size, and complexity of a conventional roller hemming head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

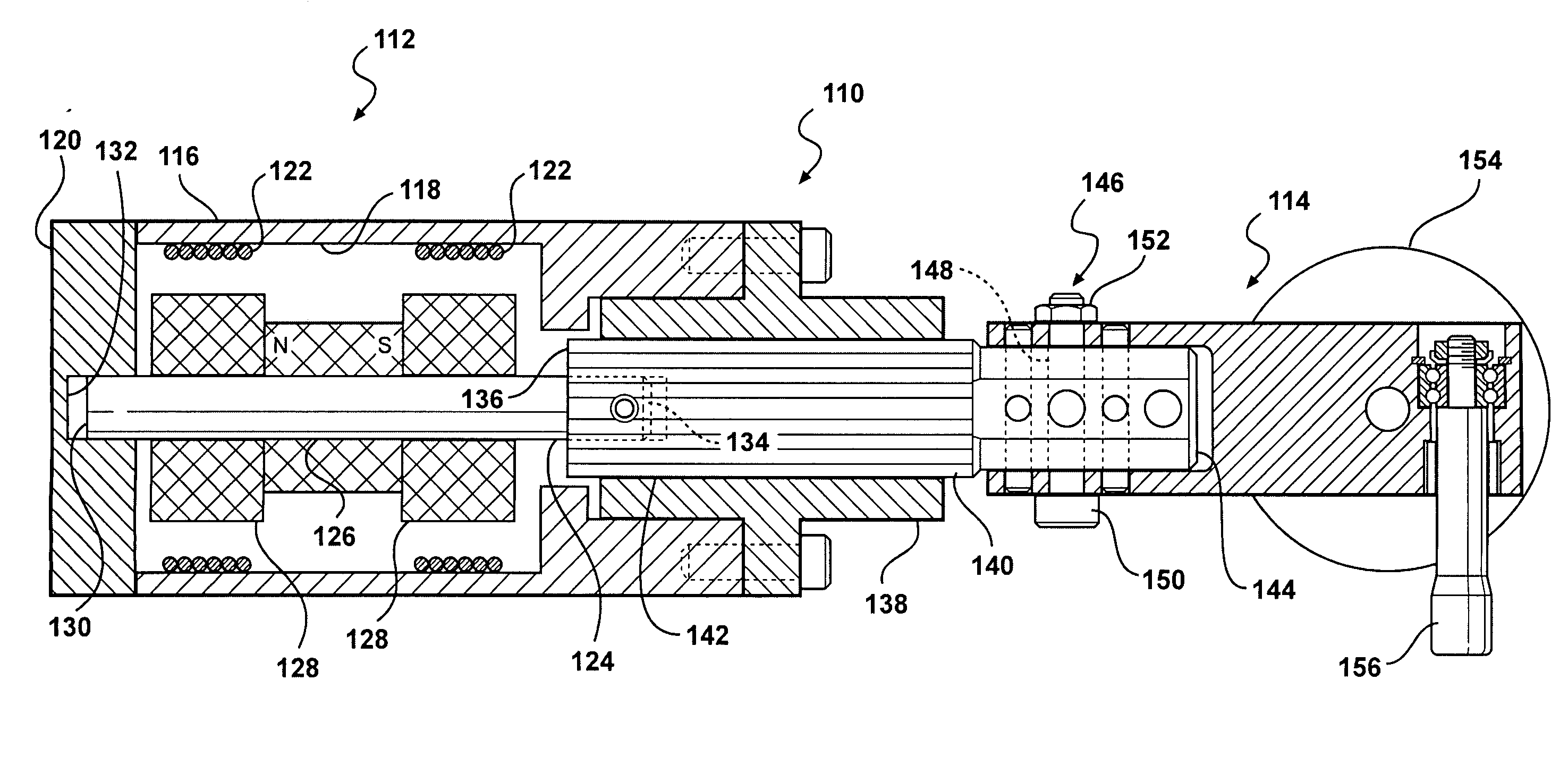

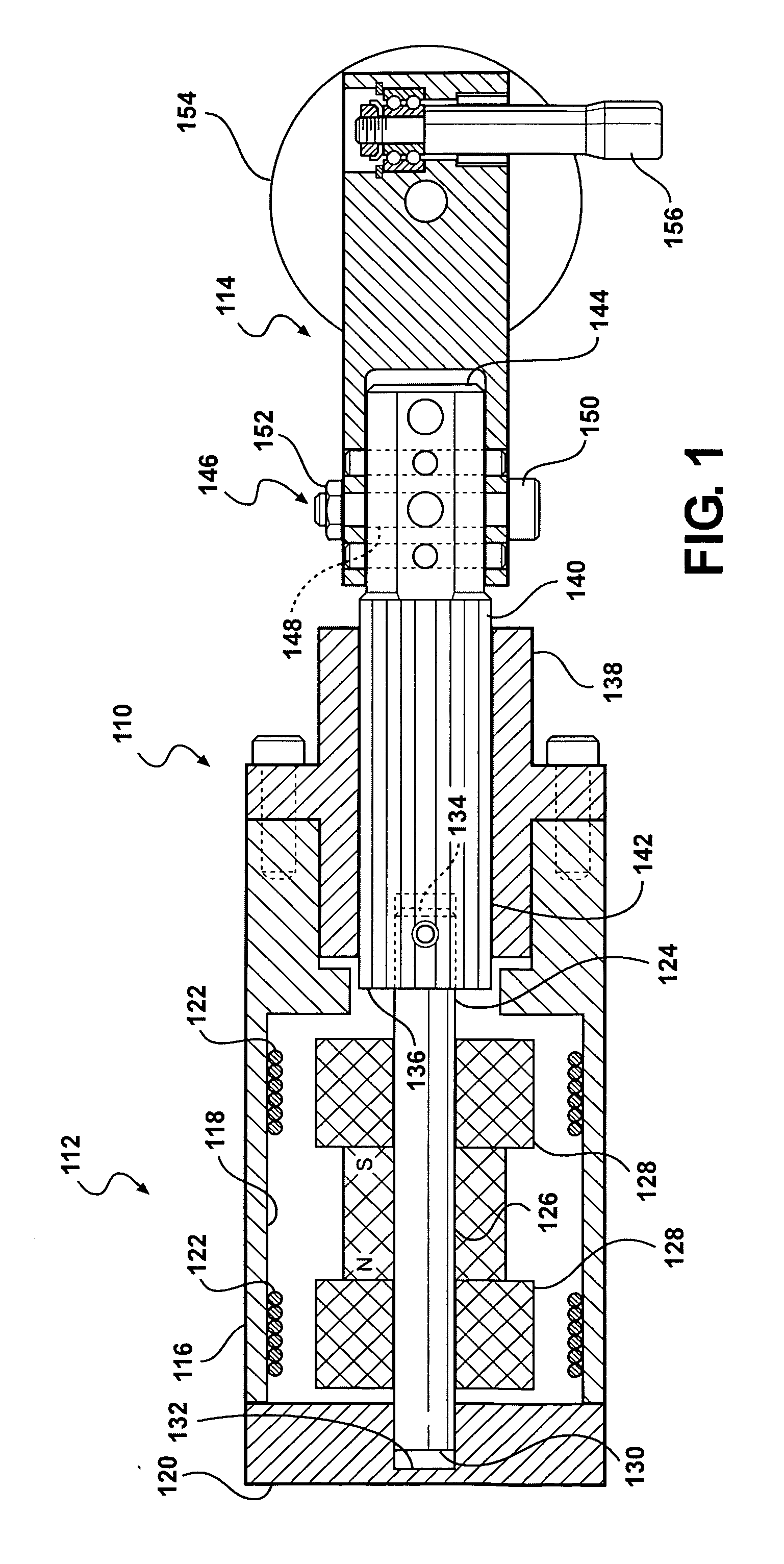

[0022]With reference to FIG. 1, in a first embodiment the magnetically actuated roller head 110 includes a linear actuator 112 mountable on an end of a multi-axis robotic arm (not shown). A roller hemming head 114 is mounted on the linear actuator 112. The linear actuator 112 provides a hemming force for performing roller hemming operations with the roller hemming head 114.

[0023]The linear actuator 112 includes a housing 116 that has an inner bore 118 that generally extends through the housing. An end cap 120 is mounted on an end of the housing 116 and closes an end of the inner bore 118. The end cap 120 may include a feature such as a mounting surface for mounting the linear actuator 112 on a robotic arm.

[0024]A pair of opposing actuator members 122 are fixedly mounted within the inner bore 118. A shaft 124 extends through the actuator members 122. A magnet 126 is mounted on the shaft 124 and is moveable within the inner bore 118. The magnet 126 is disposed between the actuator mem...

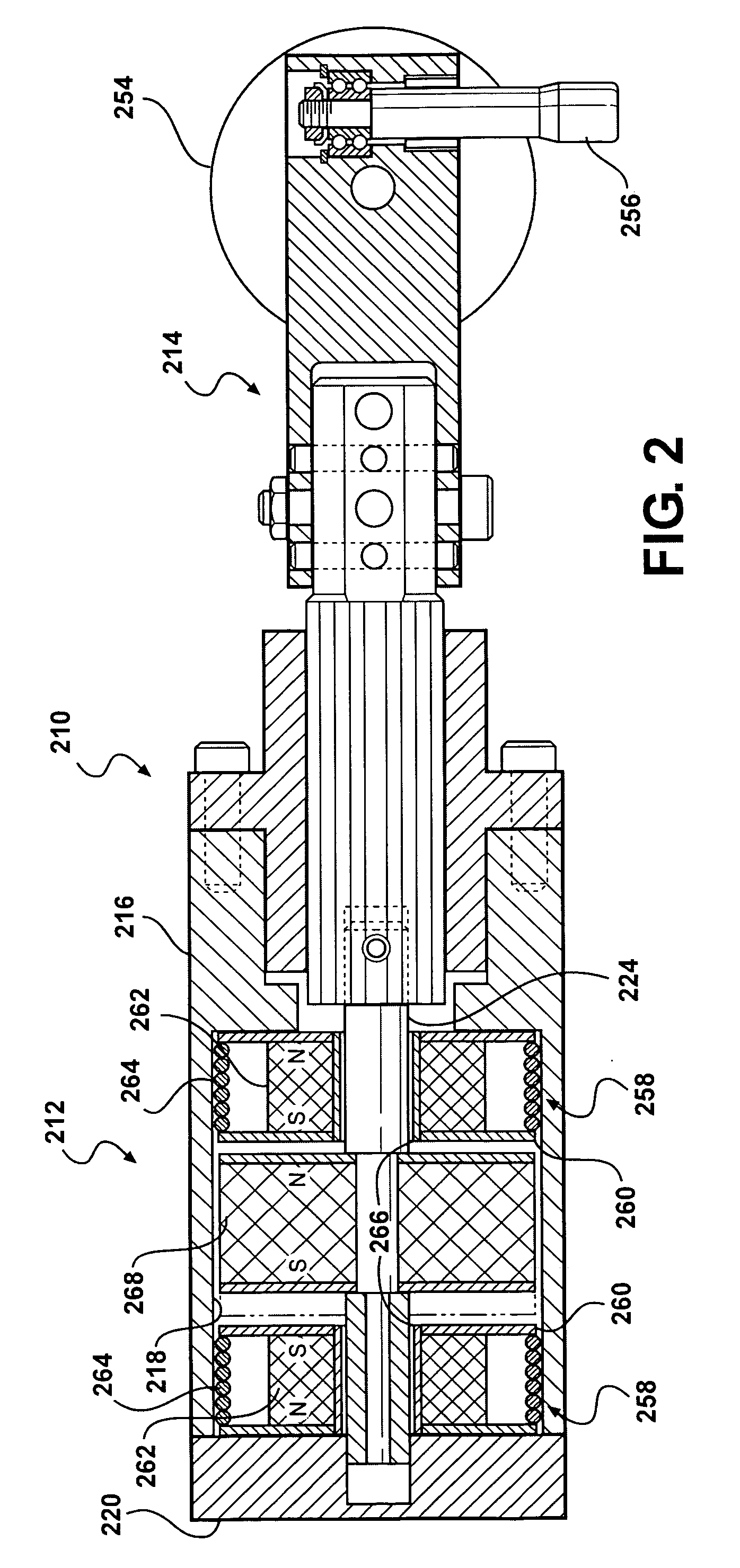

third embodiment

[0037]In the third embodiment, the housing 316 and shaft 324 may be non-magnetic so as to not interfere or interact with the magnetic field of the rare earth magnets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com