Making process of stainless steel belt for composite aluminium-steel contact rail

A stainless steel strip, steel-aluminum composite technology, applied in manufacturing tools, other manufacturing equipment/tools, drive devices for metal rolling mills, etc. Satisfy the effects of mass production, reasonable process design and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

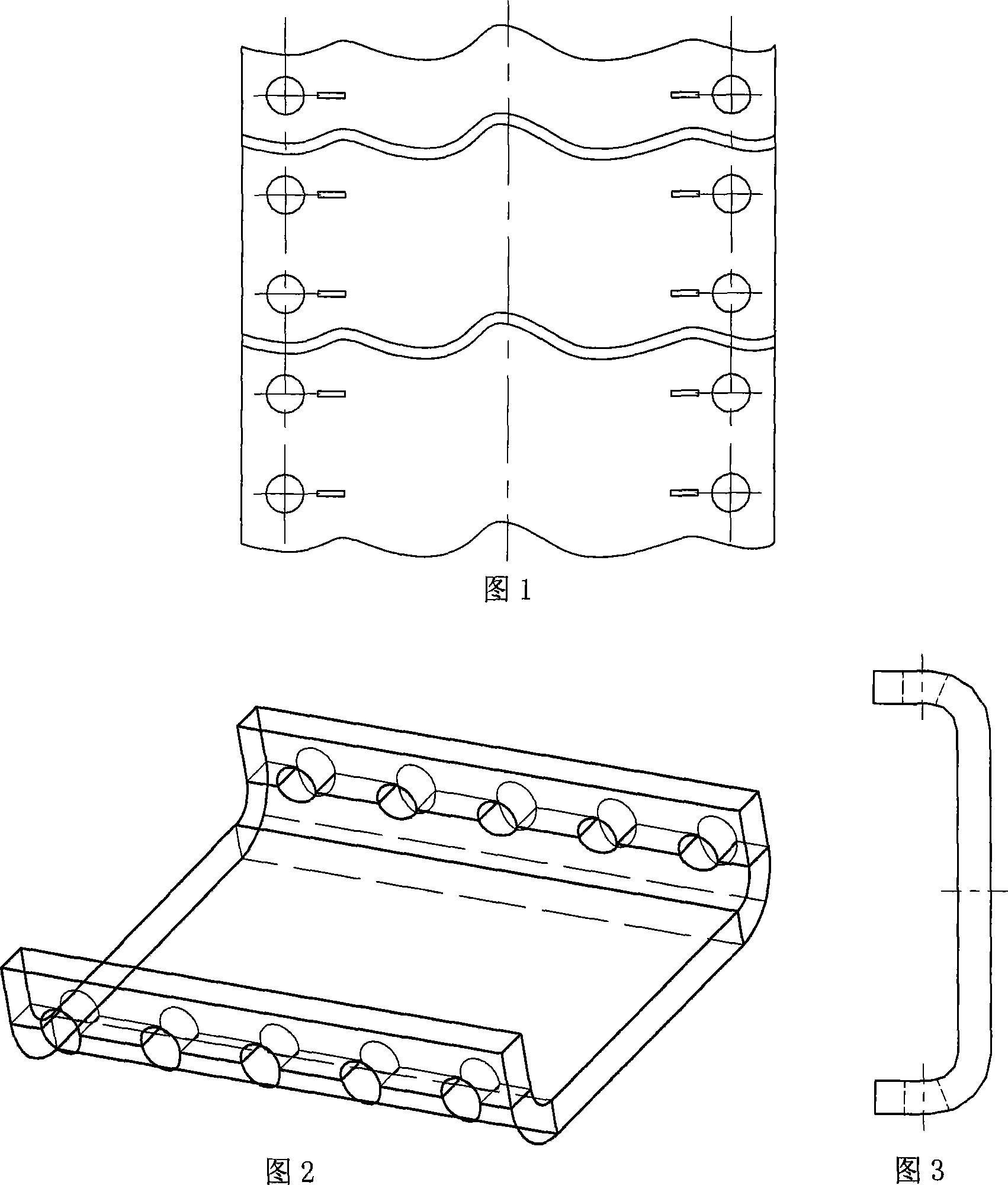

Image

Examples

Embodiment Construction

[0024] In the invention, the pre-cut stainless steel strip coil material is uncoiled, and then leveled to ensure that the surface of the steel strip is straight, and then punched on the surface of the steel strip, and then continuously sent to the special cold-bending forming equipment for gradual cooling. Bending into shape, and finally cut to length according to the actual required length. The specific method is as follows:

[0025] A method for manufacturing a stainless steel strip for a steel-aluminum composite contact rail of the present invention, comprising the following steps:

[0026] 1) First unroll the stainless steel coil installed on the uncoiler; the uncoiler is composed of a welding frame, a tensioning shaft system, a motor reducer drive, a binder head and a brake.

[0027] 2) Use the lead leveling machine to level the unrolled steel coil, so that the steel coil becomes a flat steel strip; set the feeding rollers before and after the lead leveler to make the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com