Grinding-rubbing type millet threshing mechanism

A threshing device and millet technology, which is applied in the field of agricultural machinery, can solve the problems of high loss rate, cumbersome operation, and high breakage rate, and achieve the effects of reducing loss rate and breakage rate, improving threshing quality, and increasing cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

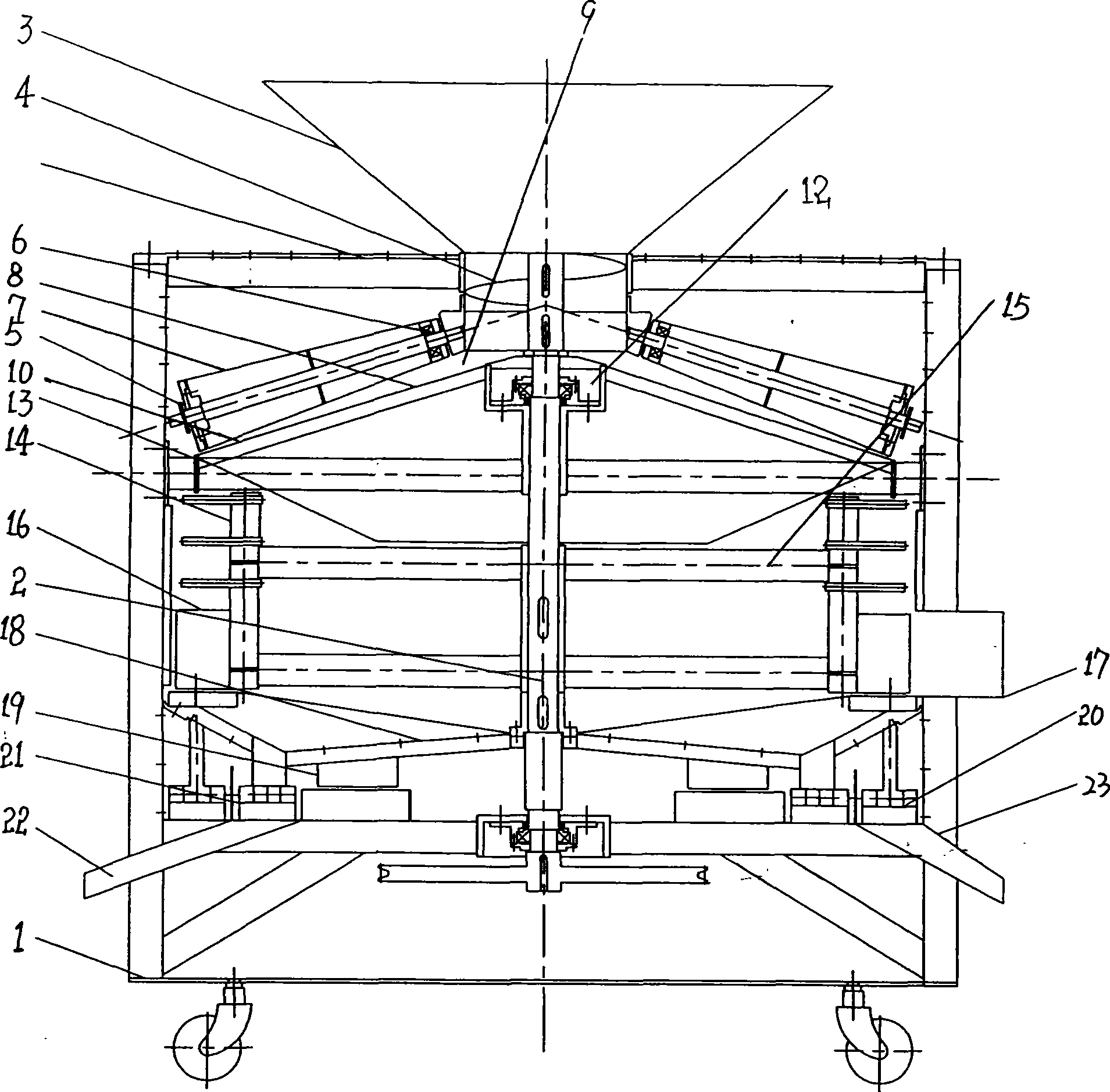

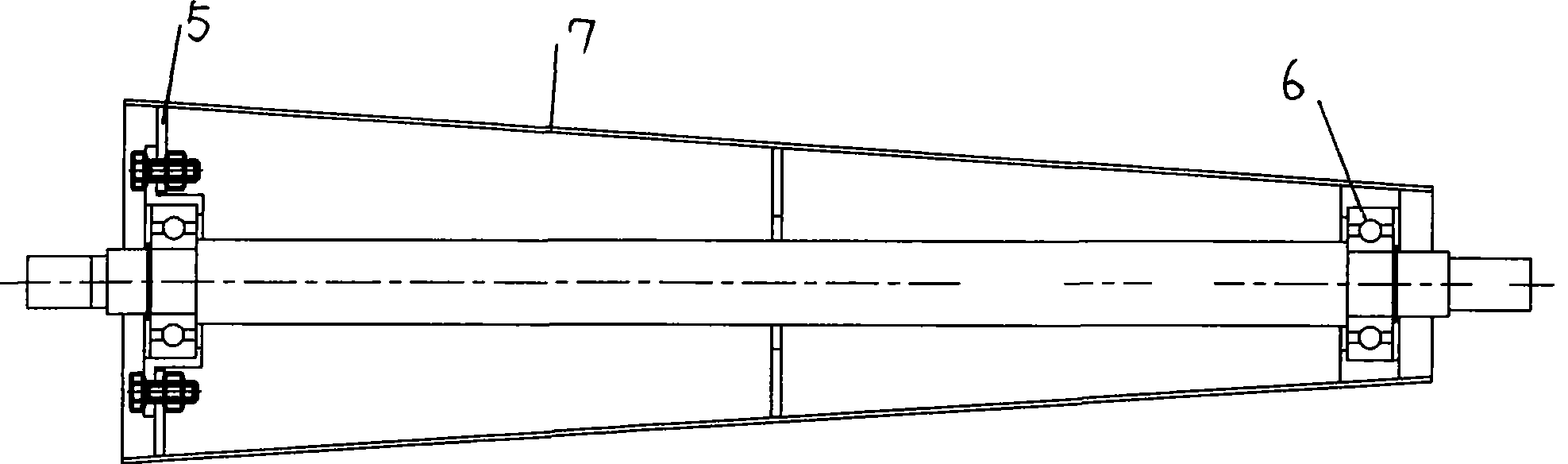

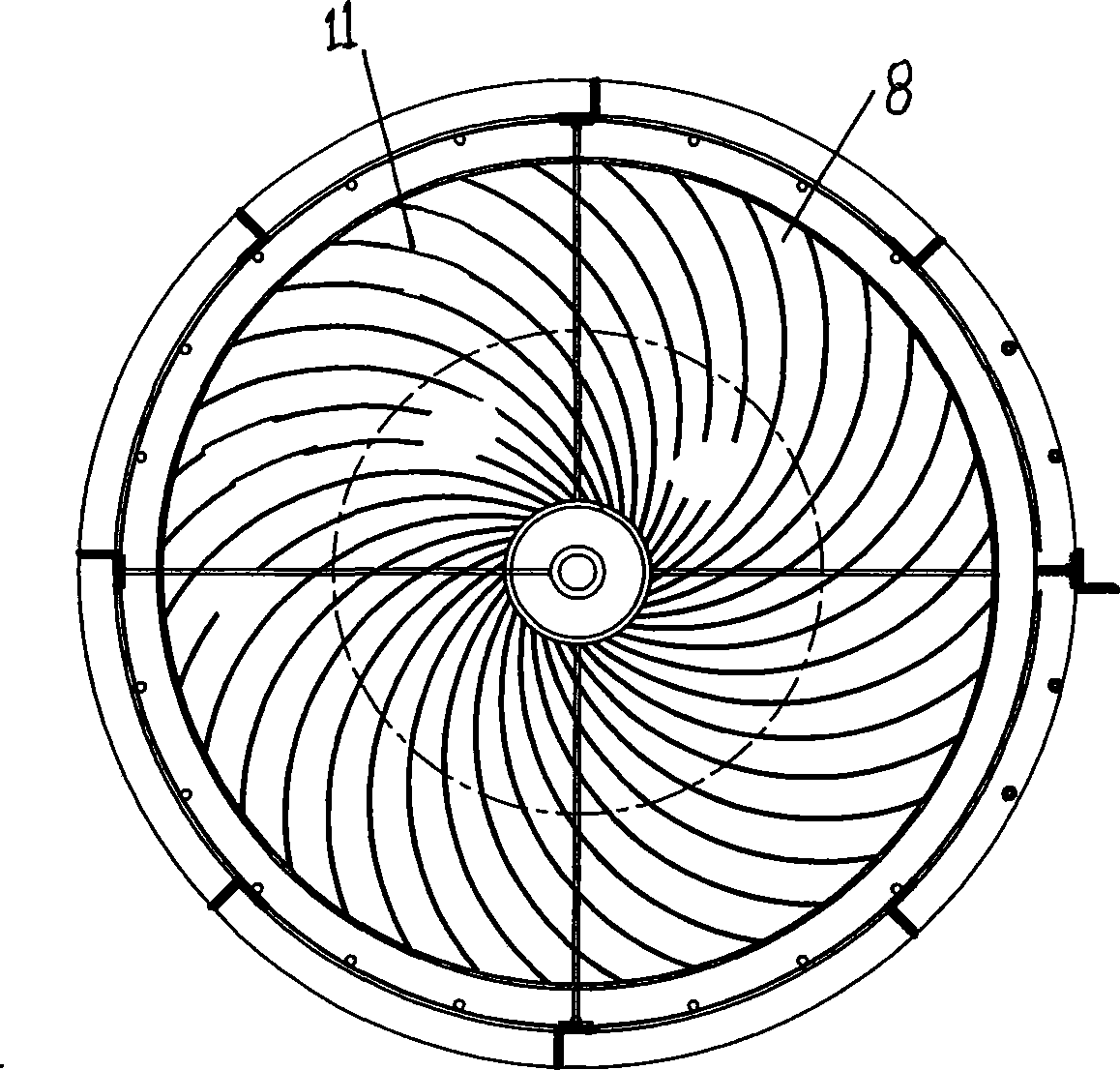

[0024] Millet millet threshing device, such as figure 1 As shown, it includes a sealed frame 1 and a main shaft 2 that is installed in the frame and controlled by a driving mechanism. A feeding hopper 3 is fixed above the frame 1, and a feeding device 4 mounted on the main shaft 2 is arranged below the feeding hopper 3. It adopts a spiral structure, specifically a welded spiral plate, with an outer diameter of 240mm; a connecting frame 5 is fixed below the feeding device 4 and on the main shaft 2, and the connecting frame 5 is supported by a rolling bearing 6, and the shaft end and the connecting frame 5 Conical rolling roller 7 fixed by bolts; under the rolling roller 7, there is a grinding pattern grid plate 8 fixed with the frame 1 and in the shape of a cone; the material outlet of the feeding device 4 is located at the rolling roller 7 And between the material inlet gap 9 of the grained grid plate 8 .

[0025] In the above structure, such as figure 2 , 5 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com