Intelligent continuous casting and rolling equipment

A continuous casting and rolling, intelligent technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of steel plate warping, waste materials, etc., to avoid curling, improve processing quality, and improve the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

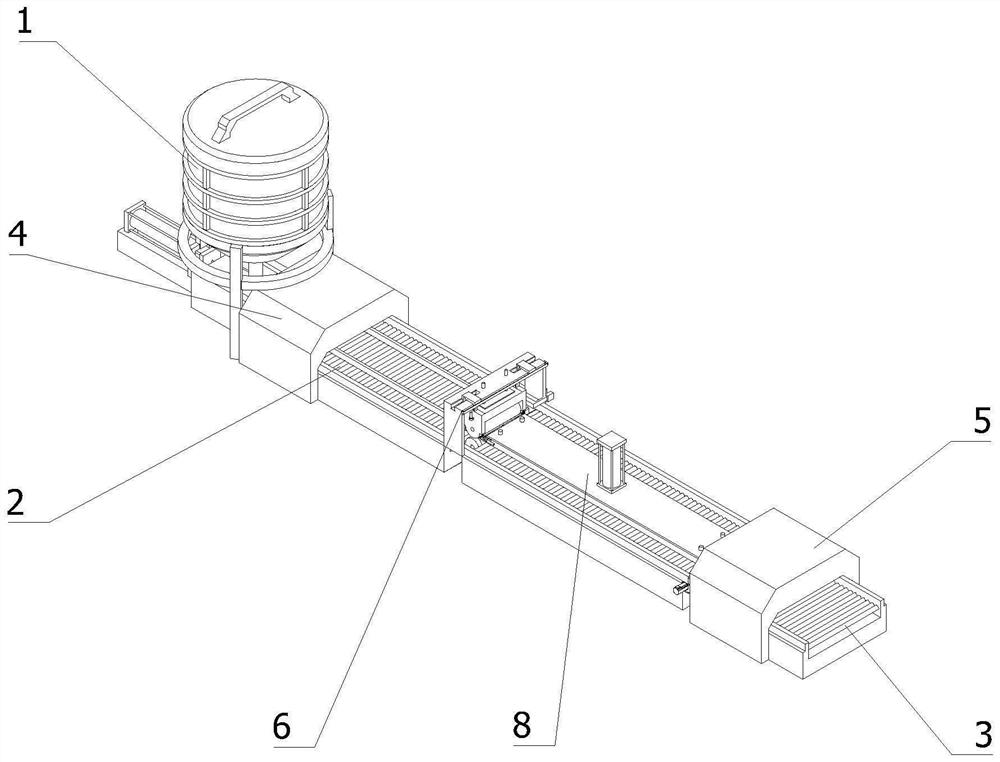

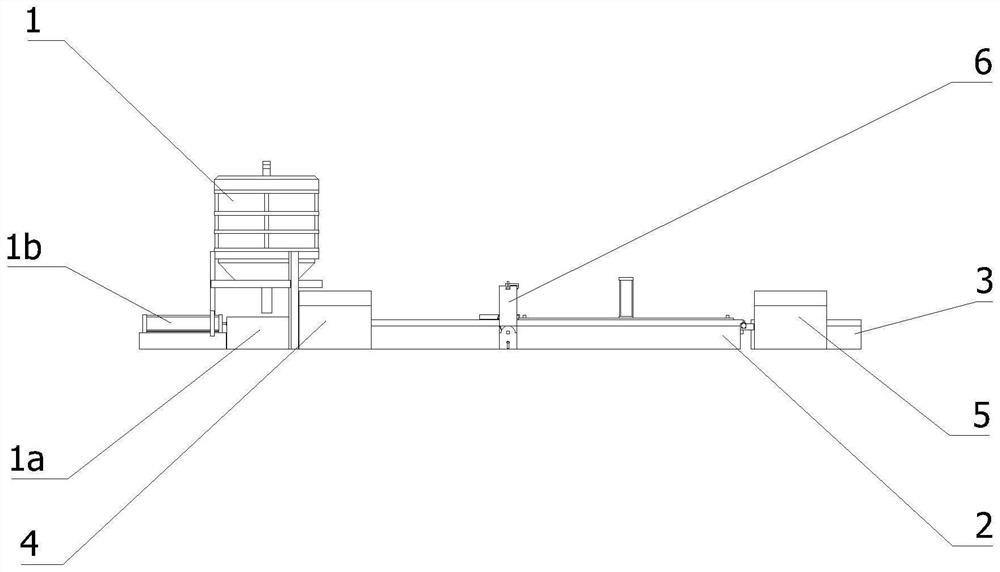

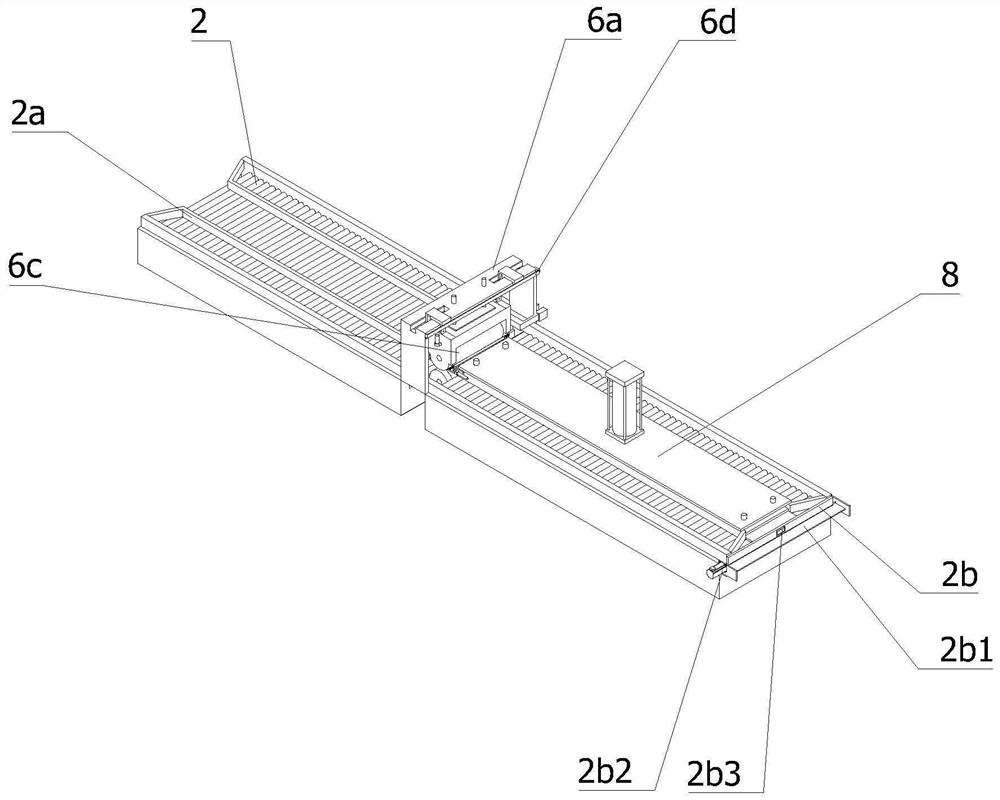

[0047] Such as Figure 1-Figure 5 As shown, this application provides:

[0048] An intelligent continuous casting and rolling equipment, including a continuous casting machine 1, a cold mold 1a arranged under the continuous casting machine 1, and a first roller conveyor 2 and a second roller arranged in sequence along the direction of the output end of the cold mold 1a Conveyor 3, a pusher 1b for pushing the solidified steel plate 1c onto the first roller conveyor 2 is provided at the cold mold 1a, and a heating chamber is also provided at the end of the first roller conveyor 2 close to the continuous casting machine 1 4. There is also a cooling chamber 5 between the first roller conveyor 2 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com