Apparatus and method for two-roll skew rolling forming of round bar

A round bar and skew rolling technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of high input cost, low production efficiency, large equipment investment, etc., and achieve low production cost and equipment. The effect of small tonnage and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

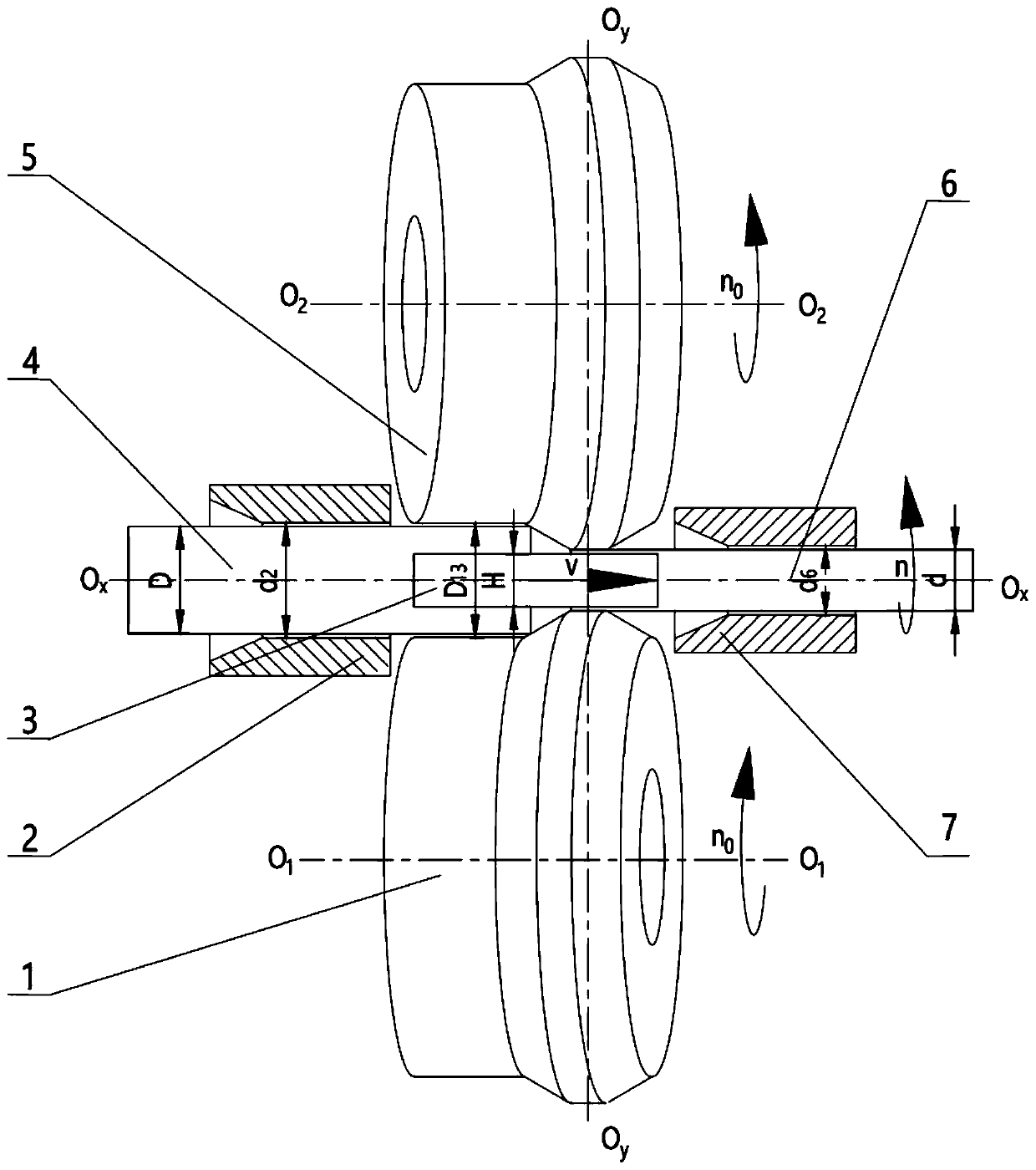

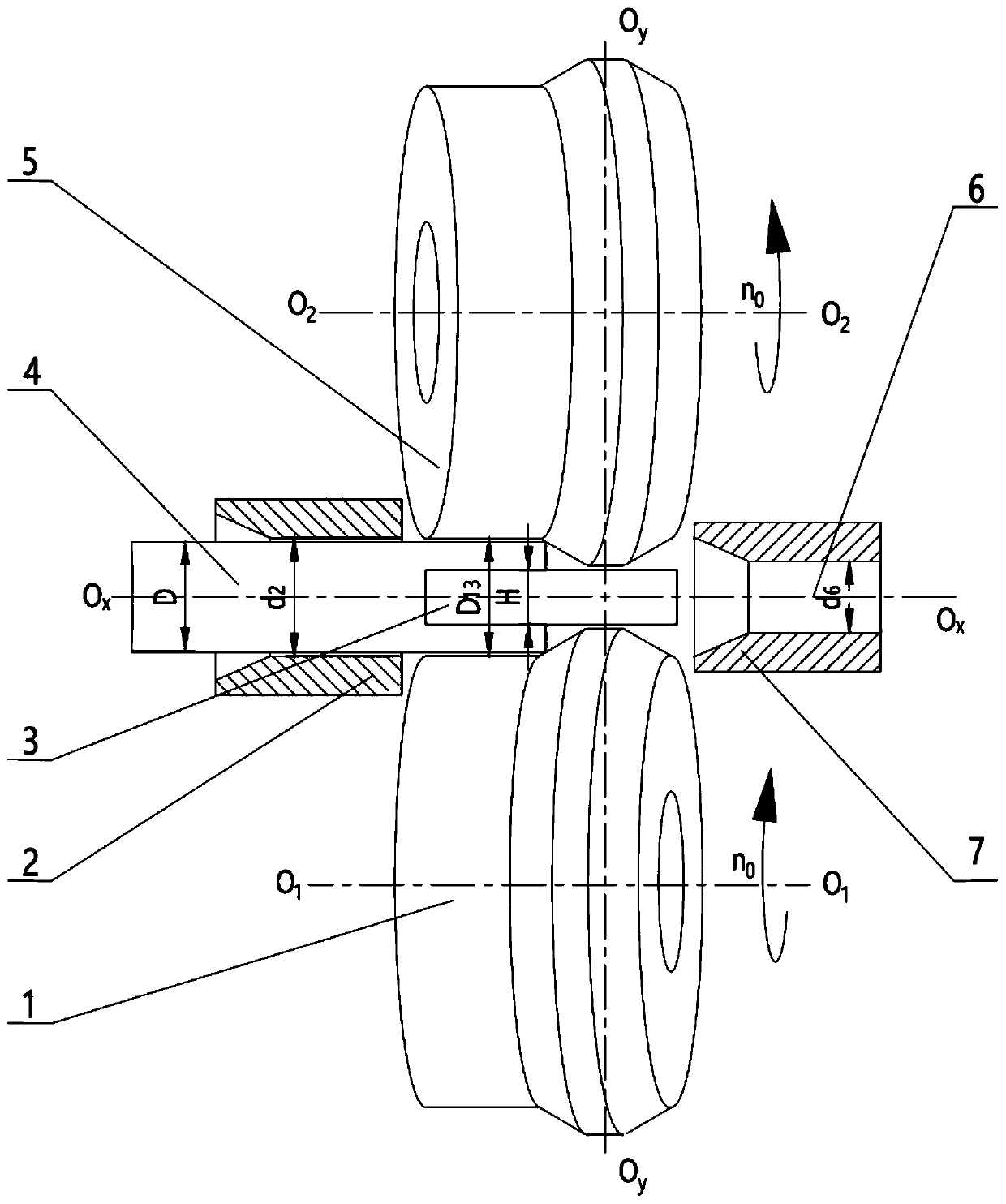

[0037] Such as figure 1 As shown, the embodiment of the present invention is a round bar two-roller cross-rolling forming device, without loss of generality, the following is illustrated by taking a Φ50mm round bar two-roller cross-rolled into a Φ35mm round bar as an example:

[0038] A two-roll cross-rolling forming device for a round bar, comprising a first skew roll 1, a second skew roll 5, a guide plate 3, a material guide cylinder 2 at a feed end, and a material guide cylinder 7 at a discharge end.

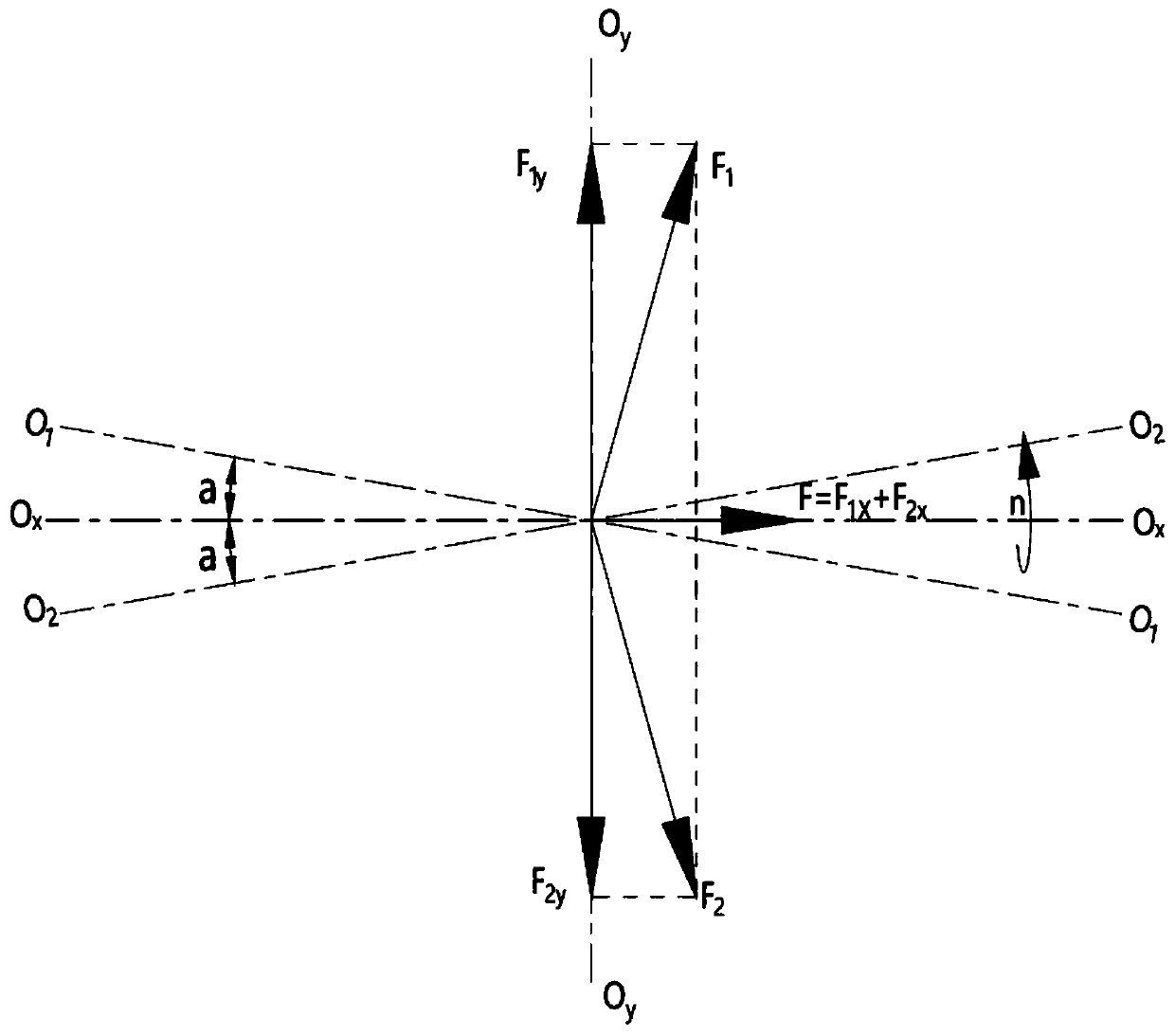

[0039] Such as figure 1 , 2 As shown, the first skew roll 1 and the second skew roll 5 are on the axis 0 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com