Disposed substance mixing plant

A stirring device and technology for processing objects, which are used in mixers with rotary stirring devices, grain processing, dissolving, etc., can solve the problem that the stirring efficiency, drying and fermentation efficiency cannot be significantly improved, the service life of the stirring blade is reduced, and the stirring rod is less affected. It can improve the stirring efficiency and drying, improve the stirring effect and drying, and achieve the effect of high stirring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

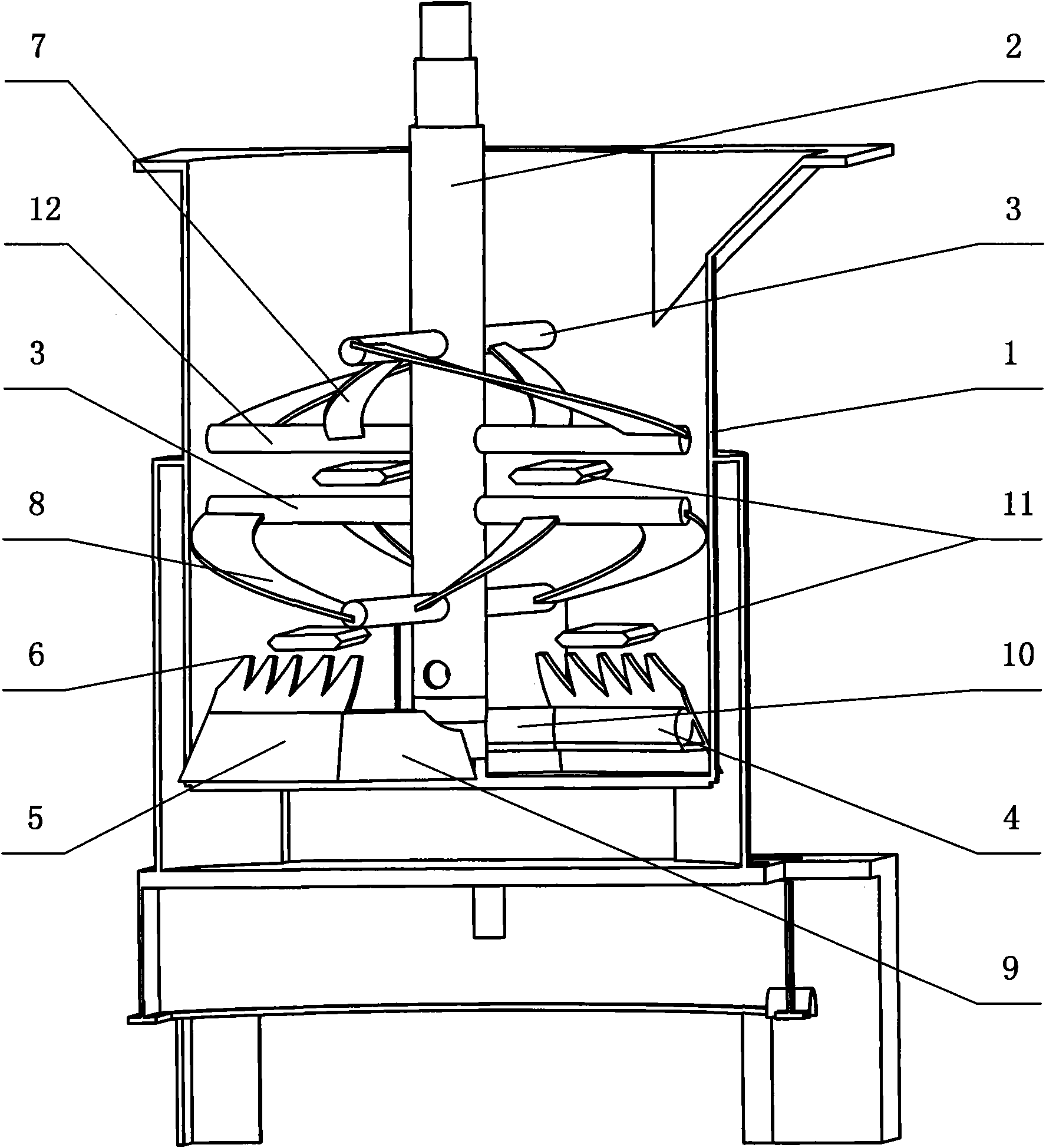

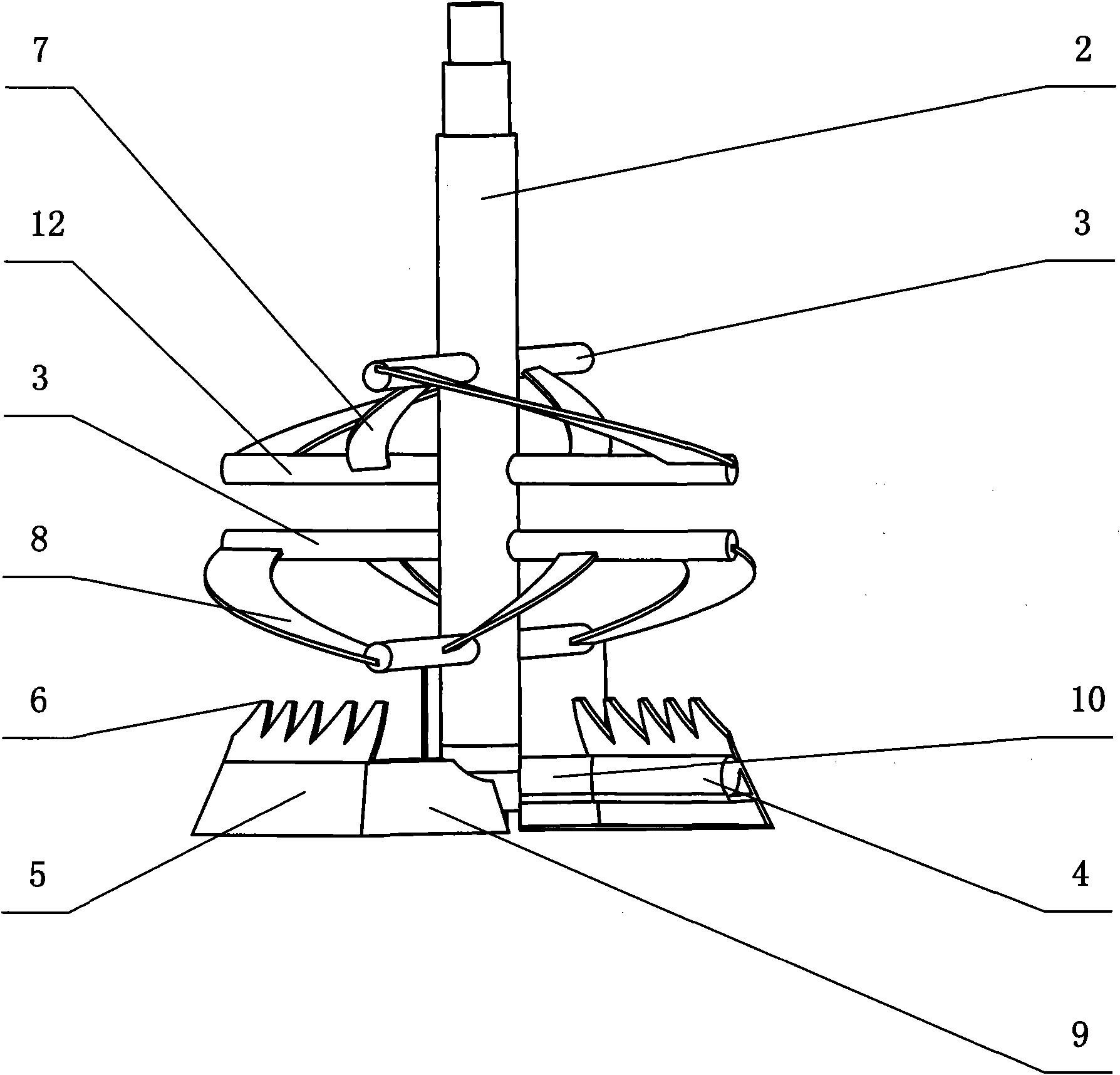

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] As shown in the accompanying drawings, a stirring device for processed objects includes a processing barrel 1 and a mixer placed in the processing barrel 1. The mixer includes a stirring shaft 2 with a transmission mechanism and a stirring rod 3, which is characterized in that the stirring rods 3 are intersected at intervals It is radially fixed on the stirring shaft 2, the lower end of the stirring shaft 2 is radially provided with a push shaft 10, the push plate 9 is provided on the push shaft 10, the end of the push shaft 10 is provided with a stirrer 4, and the stirrer 4 crosses the push shaft 10 connection, the stirring rod 4 is provided with a plow-shaped mixing blade 5, and the push plate 9 is connected with the plow-shaped mixing blade 5 to promote the lifting of the treated material and achieve the purpose of sufficient mixing. The upper end of the plow-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com