Liquid-state cosmetic mixed process treatment system

A liquid cosmetics and mixing process technology, which is applied in the field of liquid cosmetics mixing process processing system, can solve problems such as non-conformity to use requirements, high procurement costs, and high labor intensity, so as to save procurement costs, reduce production costs, and broaden the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

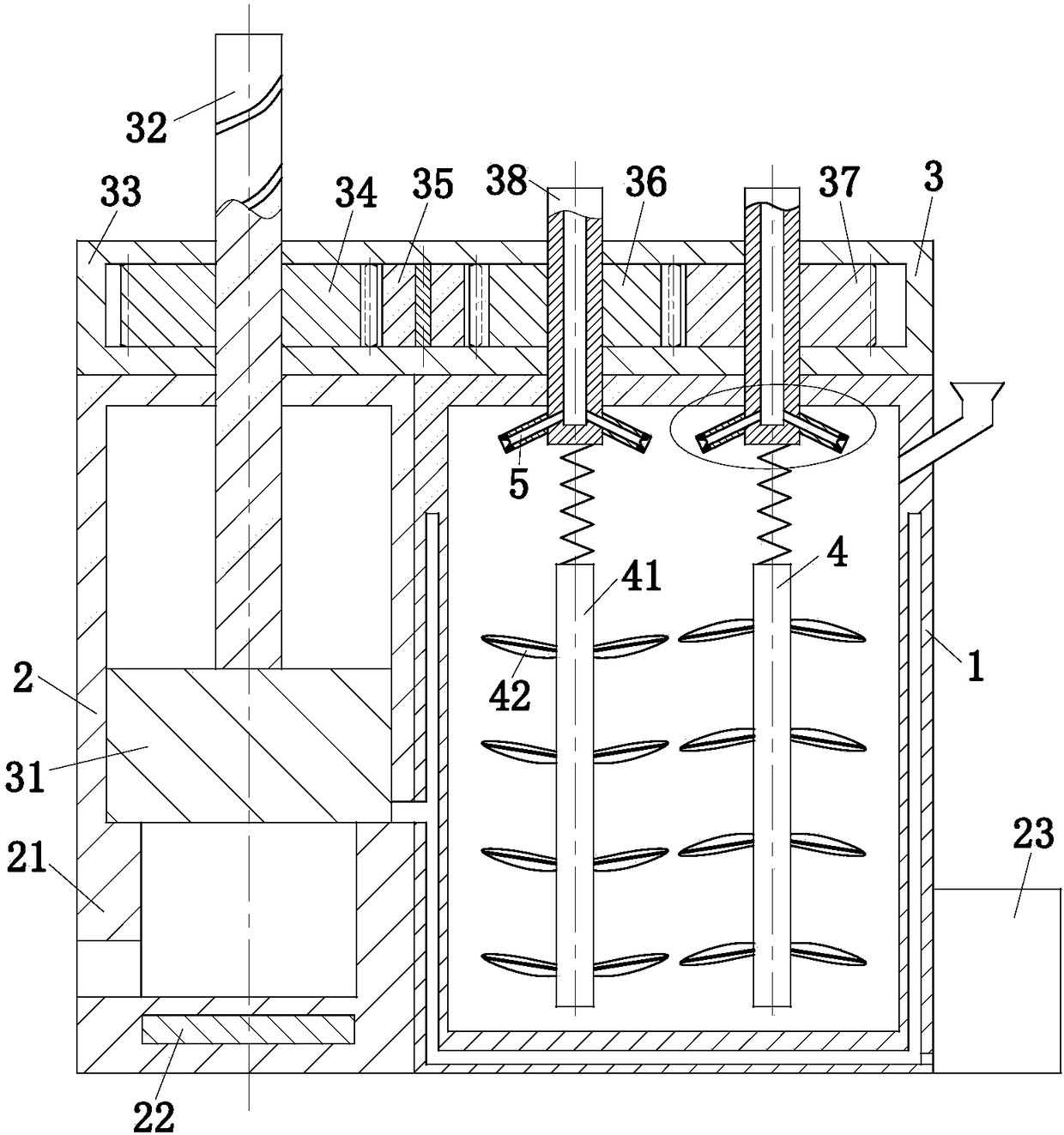

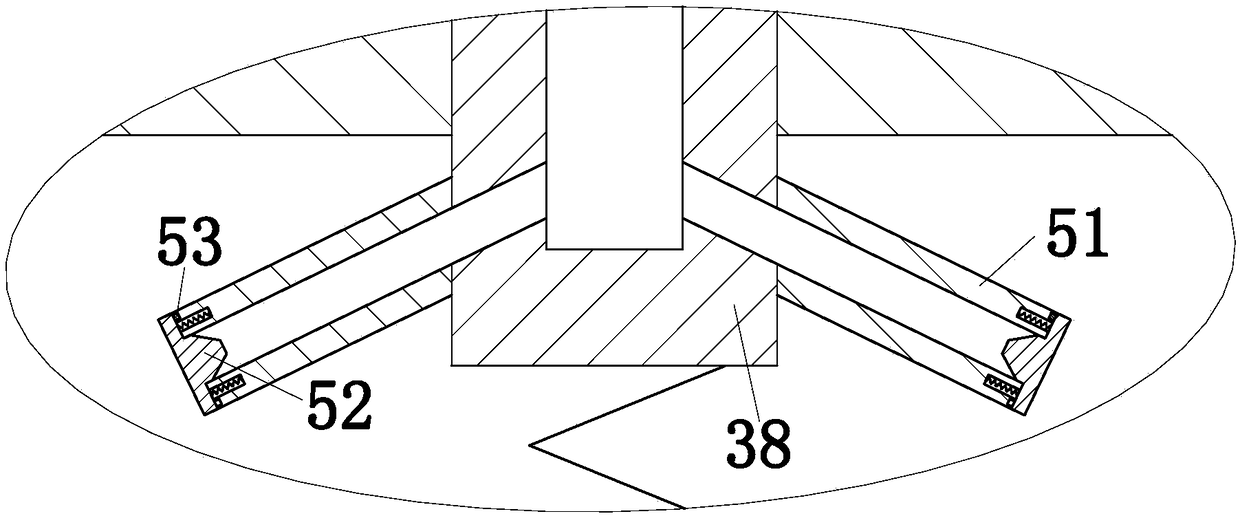

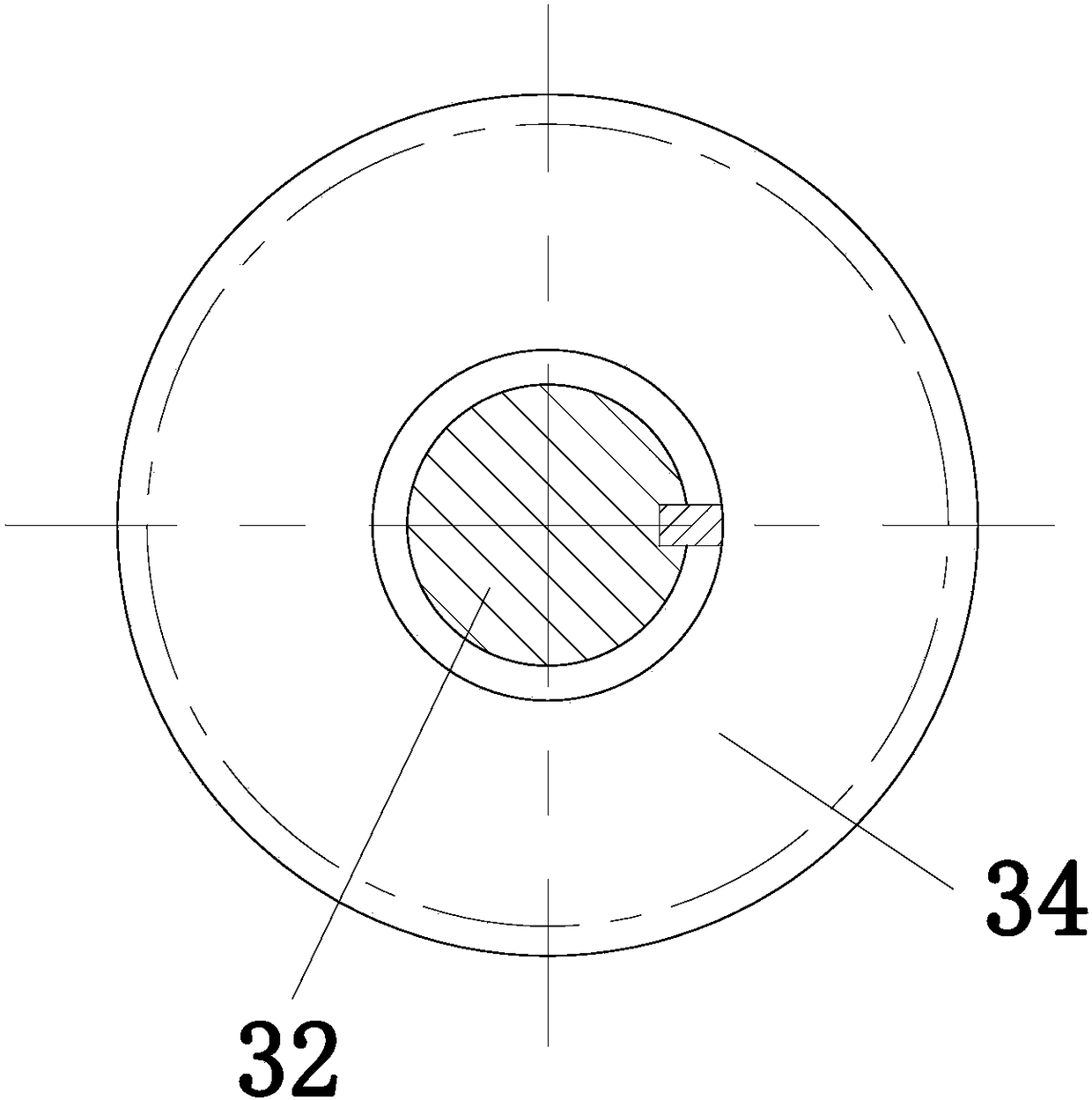

[0020] Such as Figure 1 to Figure 3 As shown, a liquid cosmetic mixing process treatment system according to the present invention includes a tank body 1, a distillation module 2, a rotating module 3, a stirring module 4 and an auxiliary material adding module 5, and the tank body 1 is used to hold The liquid raw materials and liquid cosmetics are stirred in the tank body 1, and a feed inlet is opened on the side wall of the tank body 1; the distillation module 2 is used to produce distilled water required for cosmetics, and the tank body 1 is heated by hot steam Insulation; the rotating module 3 uses the high-pressure water vapor generated during the production of distilled water as power to drive the stirring module 4 to rotate; the stirring mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com