Solvent-free glue liquid feeding device for packaging bag compounding

A feeding device, solvent-free technology, applied in transportation and packaging, mixer with rotary stirring device, dissolving and other directions, can solve the problem of inability to achieve uniform mixing, and achieve the effect of improving stirring, improving the effect of mixing, and quickly mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

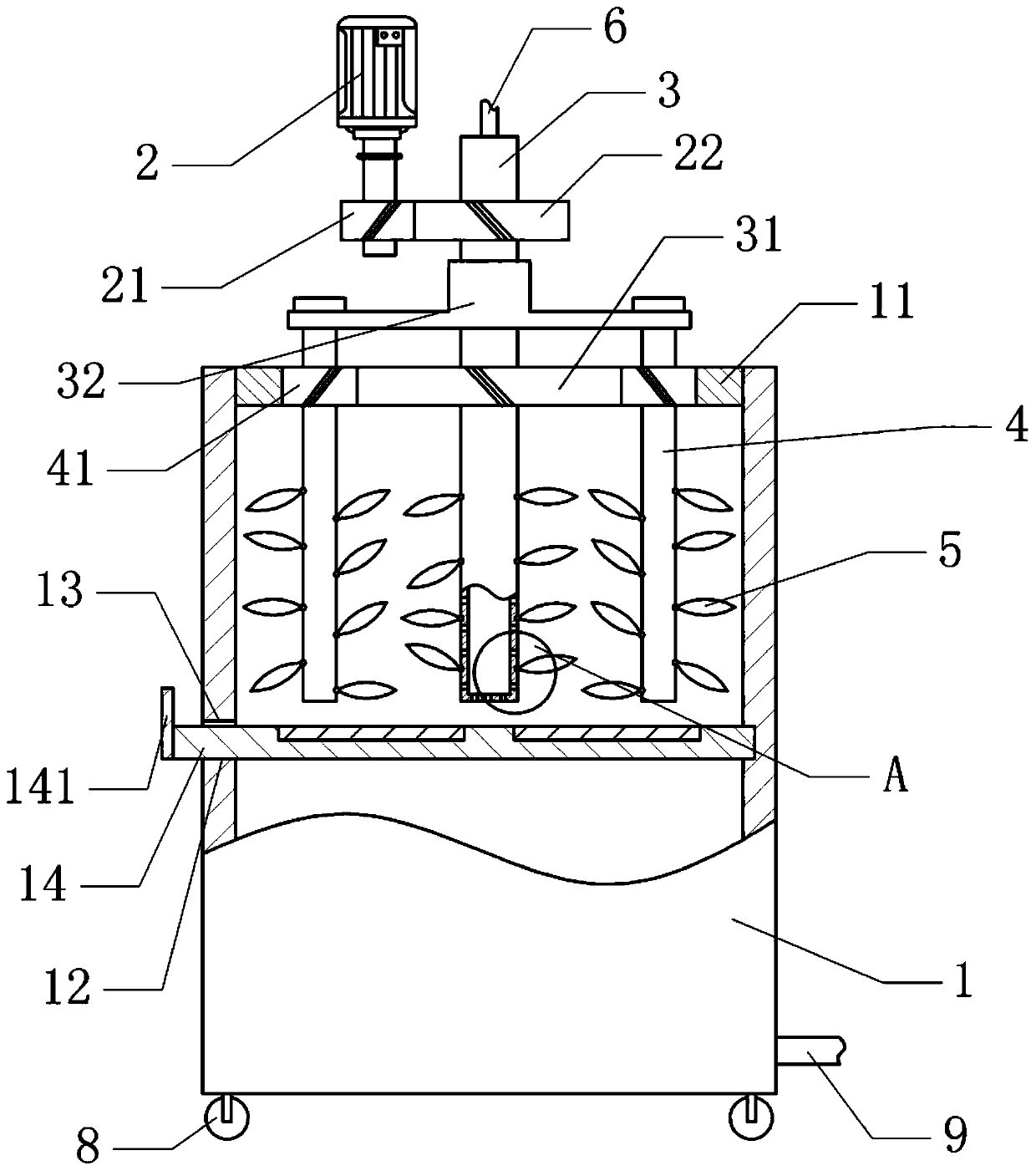

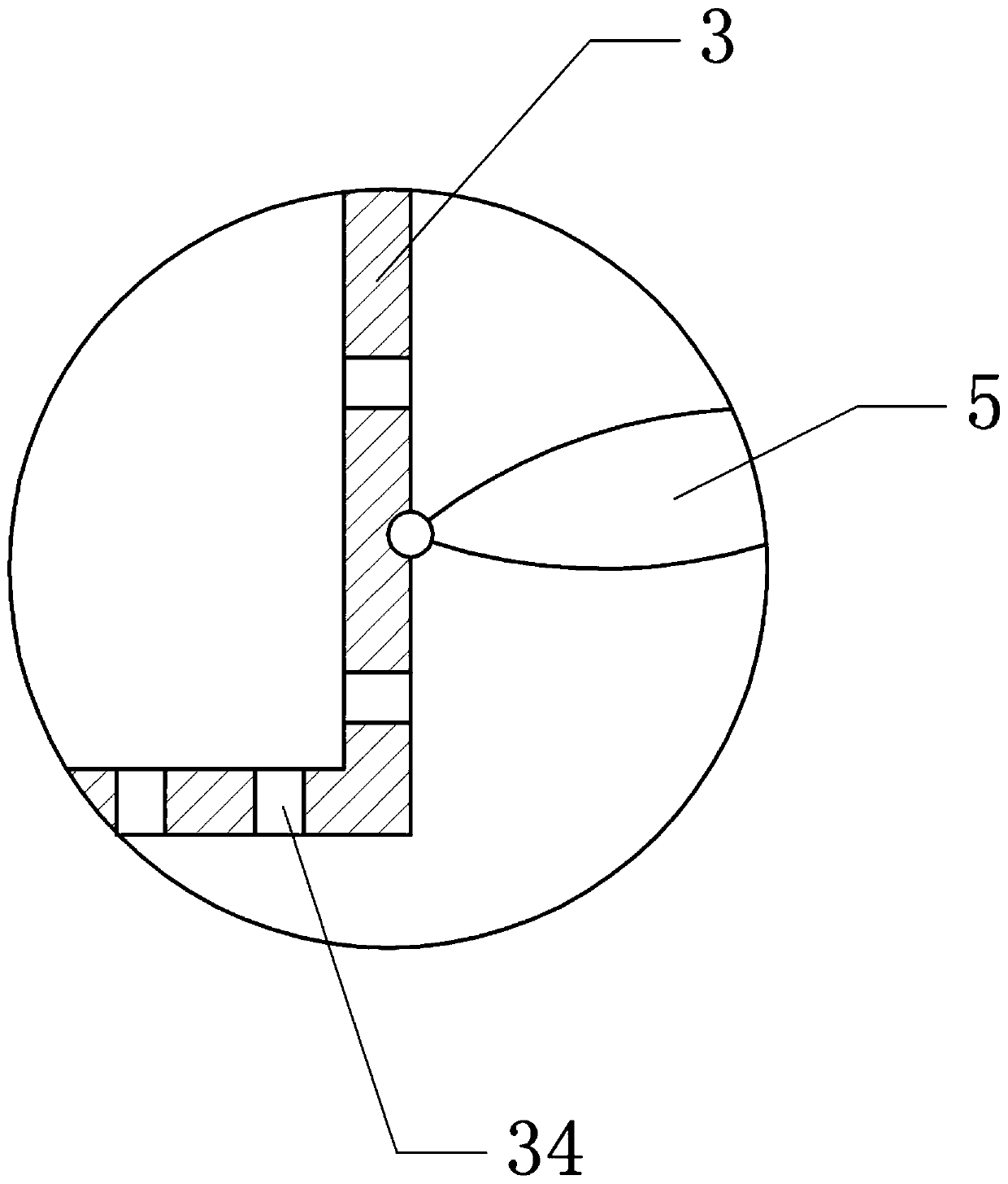

[0034] The solvent-free glue feeding device for packaging bag compounding is basically as attached figure 1 As shown, it includes a mixing bucket 1 and a bracket located above the mixing bucket 1. A motor 2 and an air inlet are fixed on the bracket. In this embodiment, the air inlet is an air pump. A driving gear 21 is fixed on the output shaft of the motor 2 . The support is also rotatably connected with a hollow rotating shaft 3, combined with figure 2 Shown, the bottom of rotating shaft 3 is provided with a plurality of through holes 34, and the diameter of through hole 34 is 2-4mm, and the diameter of through hole 34 is 3mm in the present embodiment; The gear 22 is located at the lower part of the transmission gear 22 on the rotating shaft 3 and is provided with a sun gear 31 . The air outlet end of the air pump is communicated with an intake pipe 6 , and the intake pipe 6 communicates with the middle part of the rotating shaft 3 top.

[0035] The rotating shaft 3 is l...

Embodiment 2

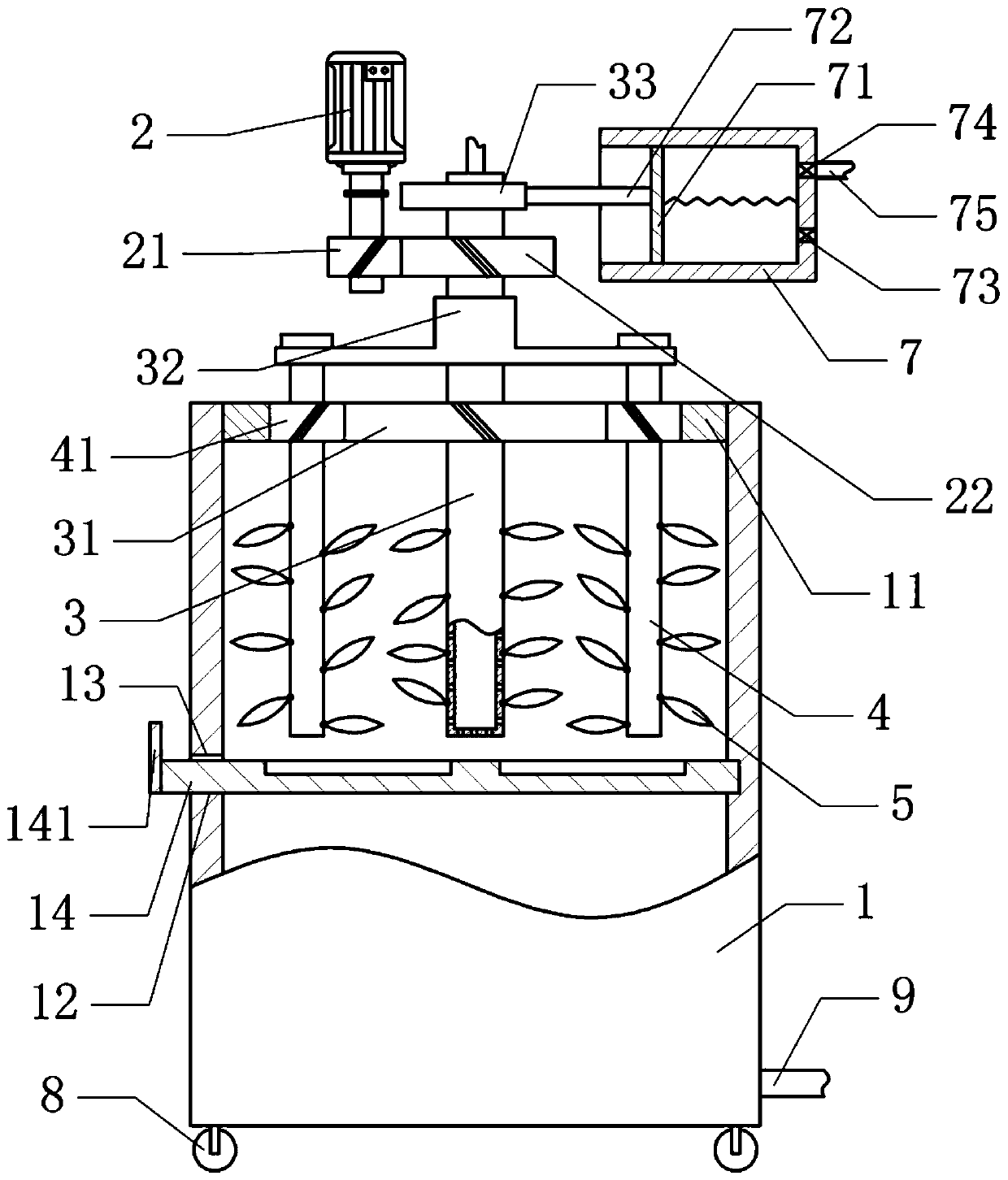

[0045] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, the air intake part includes a piston 71 barrel 7 fixed on the support, the right end of the piston 71 barrel 7 is a sealing end, the piston 71 is connected with a piston 71 in a horizontal sliding manner in the barrel 7, and a push rod 72 is fixed on the left side of the piston 71. The right end of piston 71 is welded with spring, and the right end of spring is welded on the sealing end of piston 71 bucket 7. The right end of piston 71 barrel 7 is provided with air inlet 73 and air outlet 74, is provided with air inlet check valve in the air inlet 73, and when piston 71 moves left, the pressure in piston 71 barrel 7 reduces, and external air pressure is greater than The internal air pressure of the piston 71 barrel 7, so the gas enters the piston 71 barrel 7 through the air inlet 73; the gas outlet 74 is provided with a gas outlet check valve, when the piston 71 moves to the right, the gas in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com