Coating processing device

A technology for processing devices and coatings, which is applied to mixers with rotary stirring devices, transportation and packaging, dissolving and other directions. It can solve the problems of poor coating quality, inability to move materials, and inability to mix materials evenly, and achieve better stirring effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

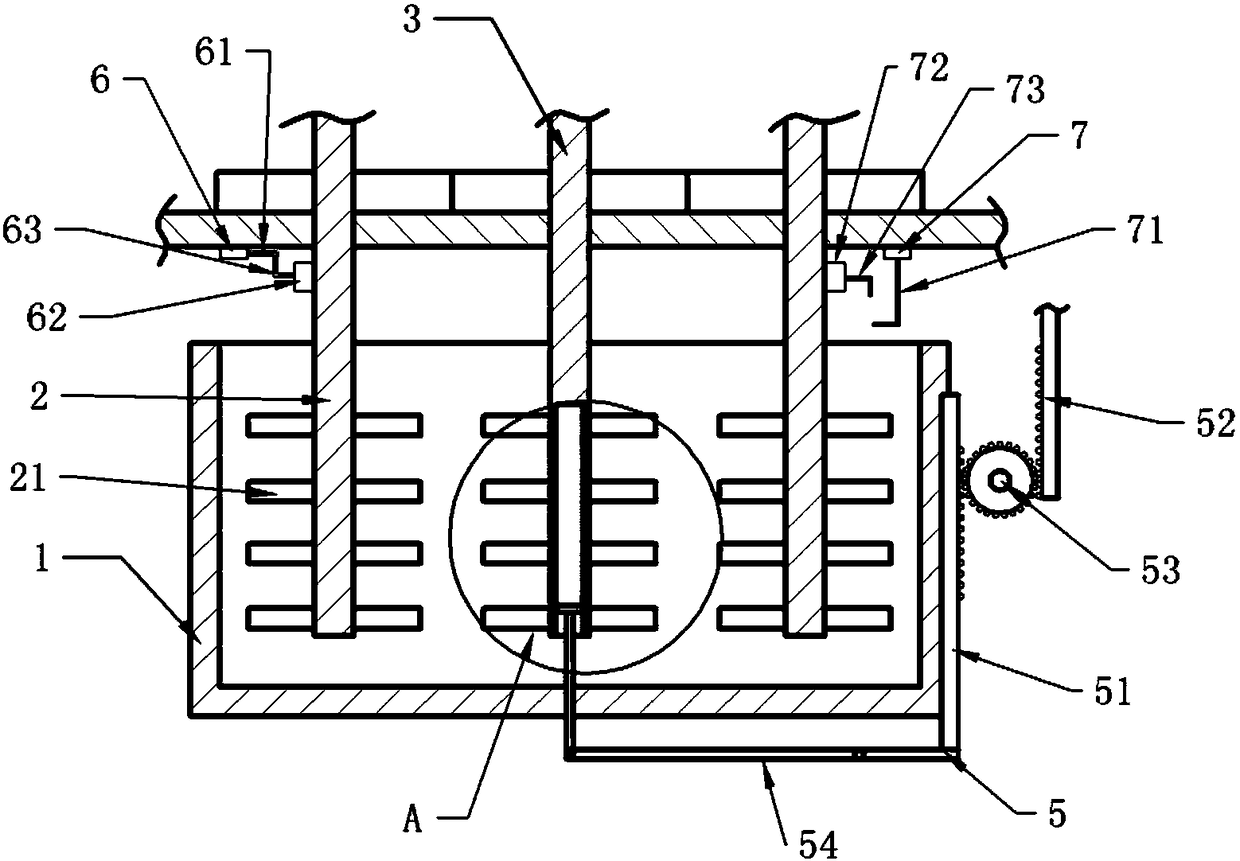

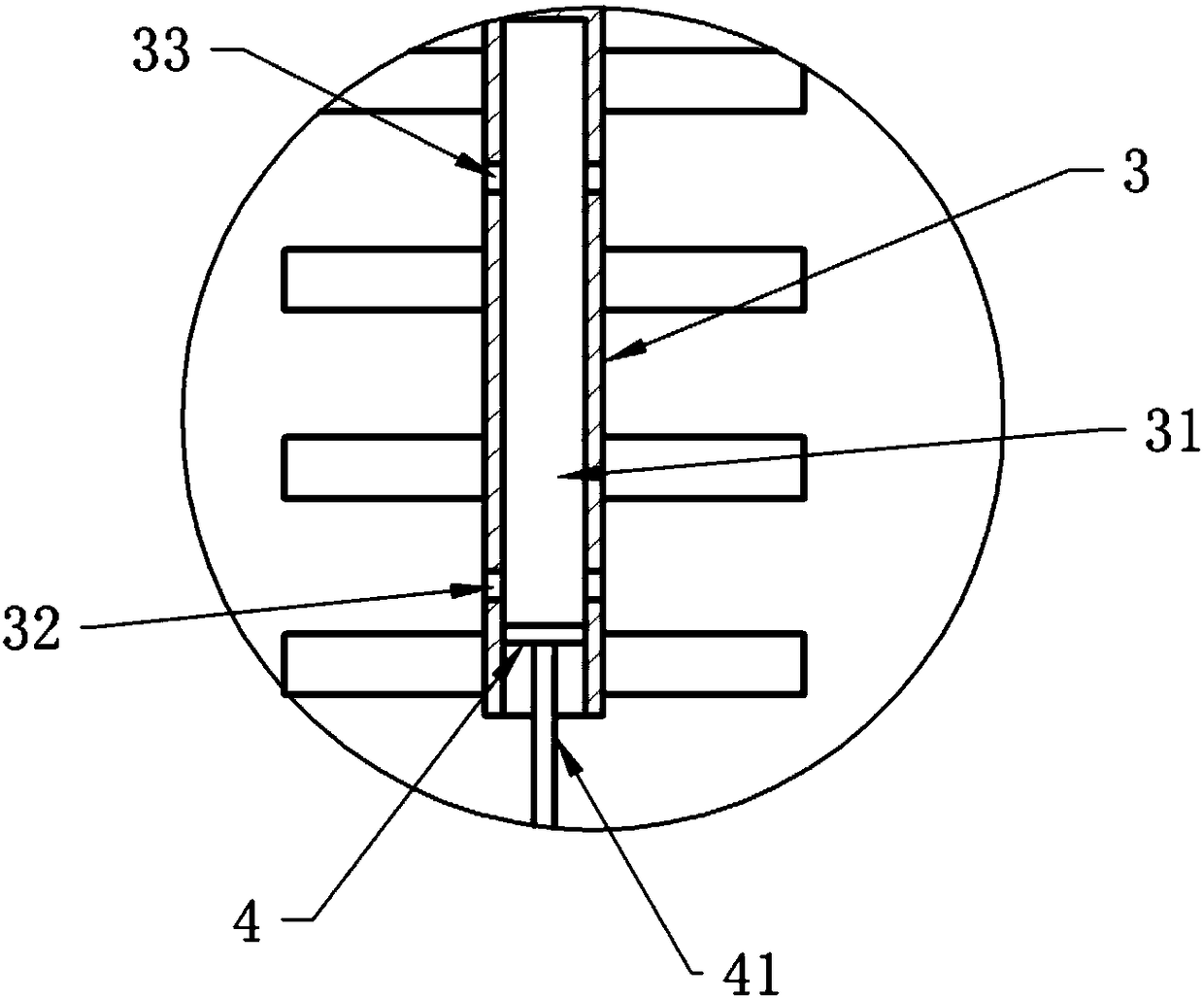

[0029] The reference signs in the drawings of the description include: mixing barrel 1, stirring shaft 2, stirring blade 21, rotating shaft 3, material guide groove 31, material inlet 32, material outlet 33, piston 4, pull rod 41, moving mechanism 5, The first rack 51, the second rack 52, the rotating gear 53, the support rod 54, the first electromagnet 6, the first conductive sheet 61, the first power supply 62, the first conductive needle 63, the second electromagnet 7, the first Two conductive sheets 71 , a second power source 72 , and a second conductive needle 73 .

[0030] like figure 1As shown, a paint processing device includes a frame, a mixing barrel 1 is installed on the frame, and two threaded holes are also arranged on the frame. Also includes two stirring shafts 2 and a rotating shaft 3, the upper part of the stirring shaft 2 is provided with threads, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com