Moveable casting blank solidification end electromagnetic stirring device

A technology of electromagnetic stirring and solidification end, which is applied in the field of electromagnetic stirring device at the solidification end of the casting billet of a casting machine, and can solve the problems of looseness and shrinkage of the solidification end of the casting billet of a vertical casting machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The above embodiments are used to explain the claims, and the scope of protection of the present invention is not limited to the description of the above structures. What those skilled in the art do based on the suggestiveness and indication of the technical solutions proposed in the claims are different from those in this embodiment. structure, all belong to the protection scope of the present invention.

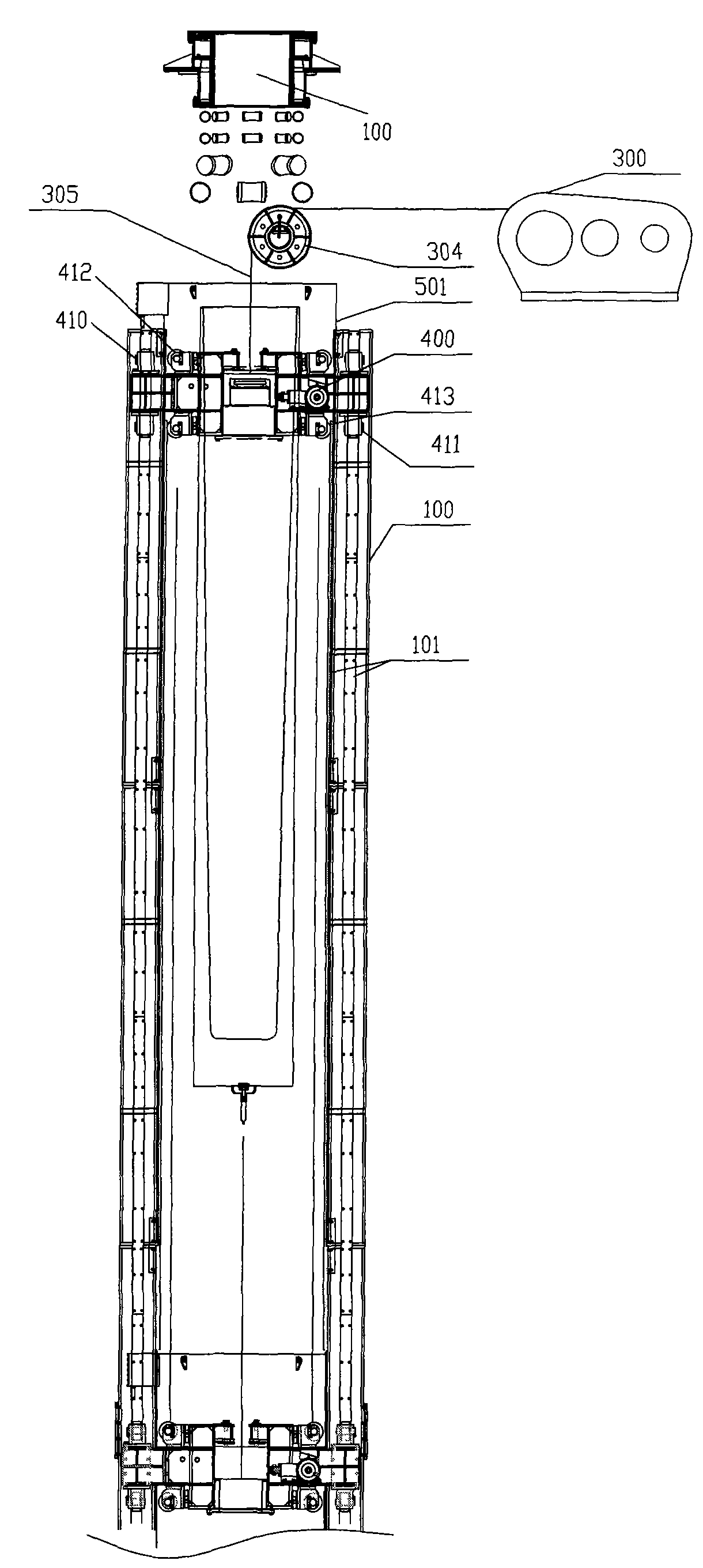

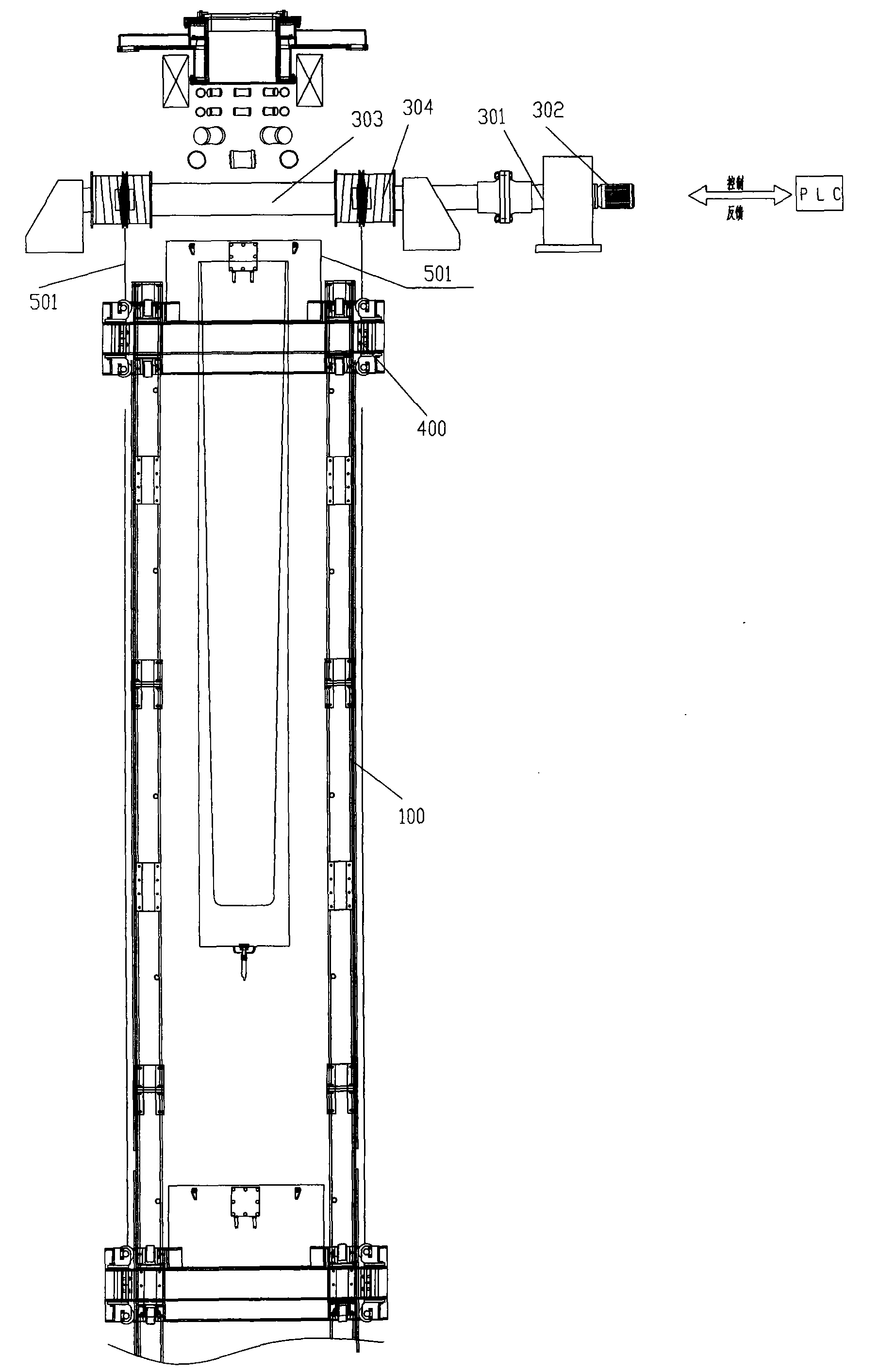

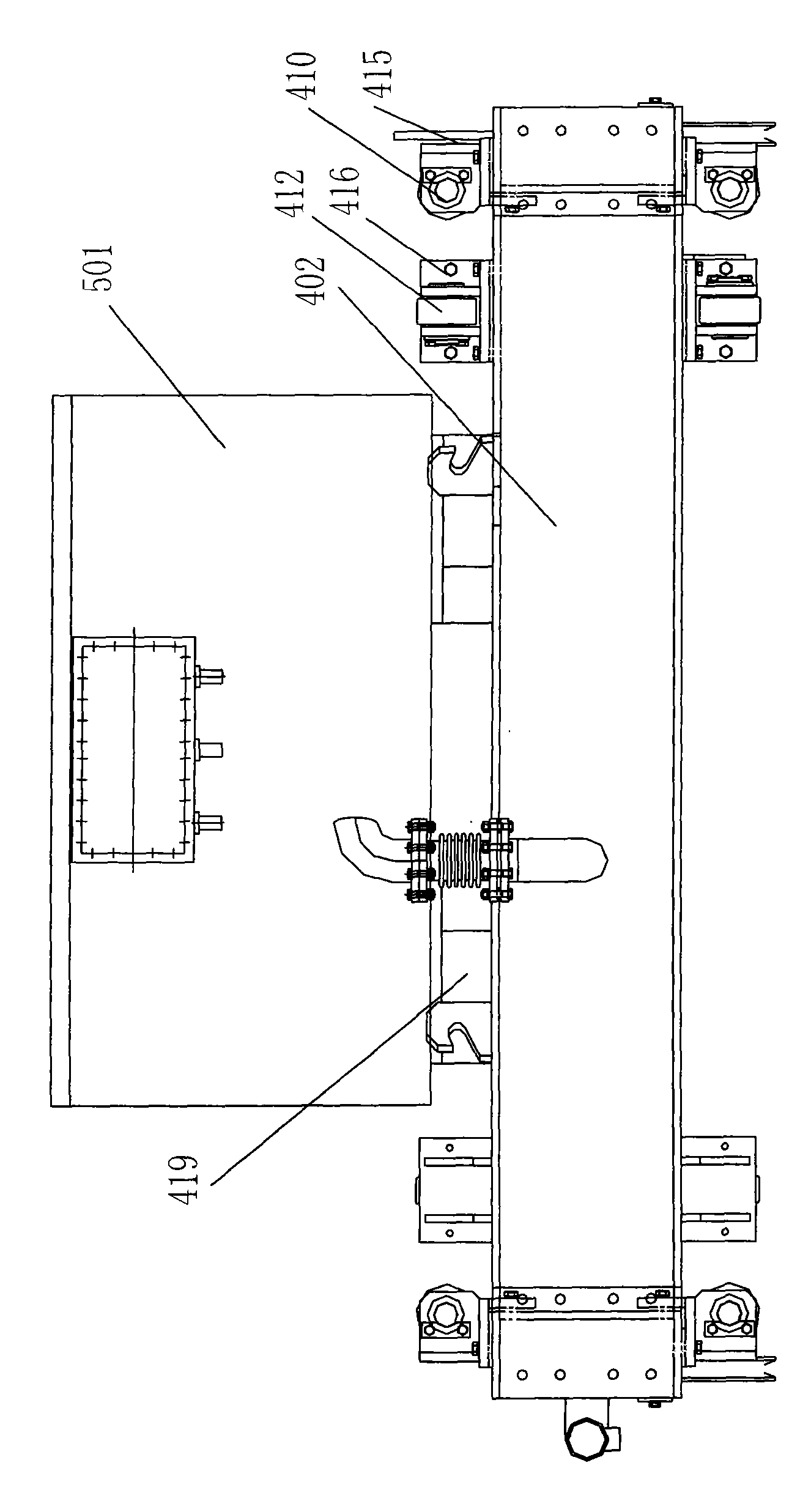

[0015] Such as figure 1 , 2 As shown, on the four water-cooled vertical track columns 100 of the vertical continuous casting machine is the crystallizer device 200; between the track column 100 and the mold device 200 is provided with a lifting drive device 300; on the track column 100 is provided with an electromagnetic stirrer installation The positioning trolley 400, the electromagnetic stirrer is installed on the positioning trolley and connected to the electromagnetic stirrer 501. A track 101 is arranged on the track column 100 . The track is arranged on two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com