Split solar water heater

A solar water heater, solar heat collection technology, applied in the directions of solar heat collectors, solar thermal energy, solar heat collectors using working fluids, etc., can solve the problems of inability to use, difficult for households to use, inflexible installation, etc., and achieve low cost Efficient heat exchange, strong water supply power, flexible and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

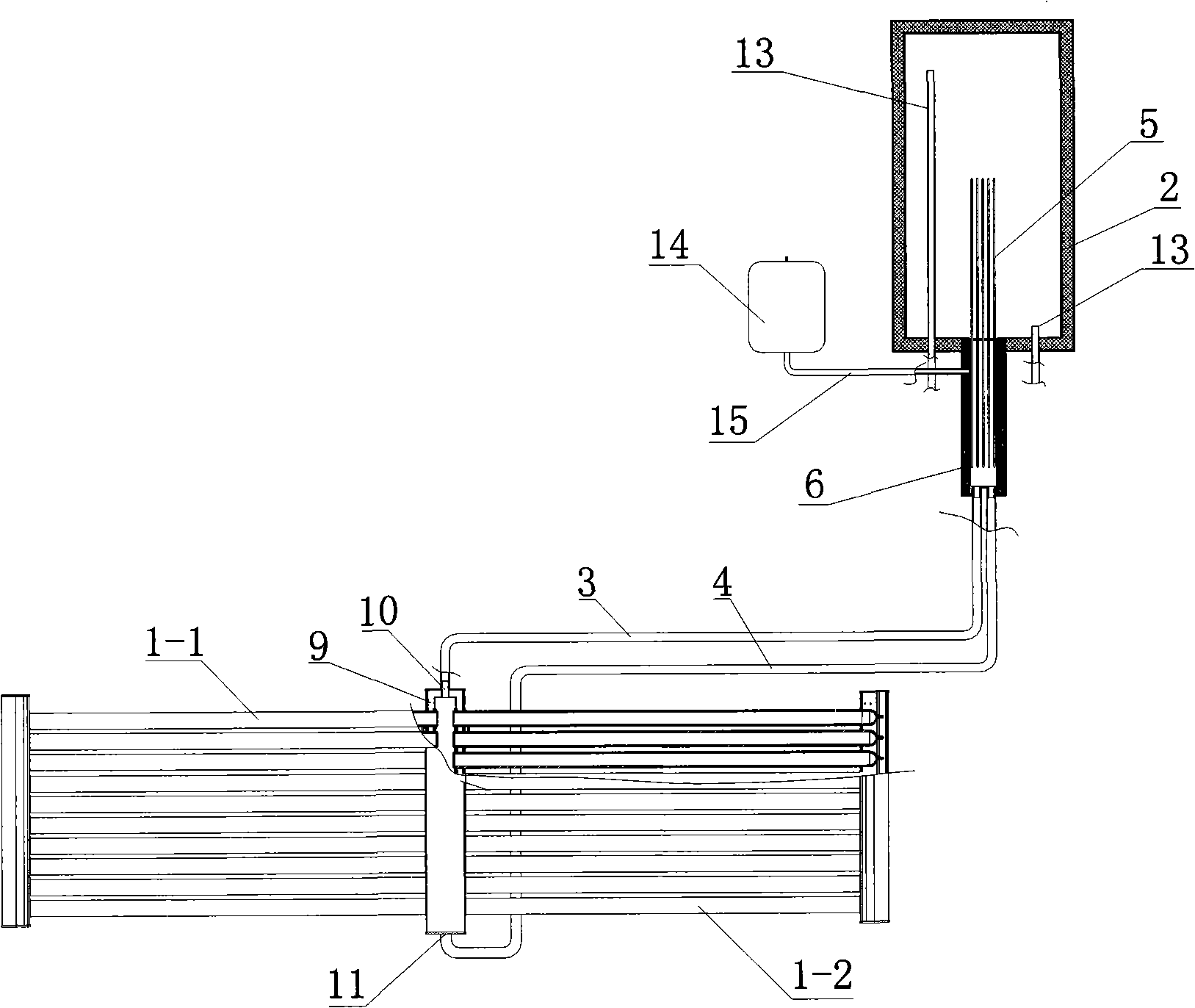

[0011] The split solar water heater of this embodiment is such as figure 1 As shown, it includes two sets of vacuum tubes 1-1, 1-2 arranged outdoors, a pressurized water tank 2 arranged indoors, an outlet connecting pipe 3 passing through the indoor and outdoor, an inlet connecting pipe 4 and twelve heat pipes 5. A connecting box 9 is provided between the two sets of horizontal vacuum tubes 1-1 and 1-2. The connecting box 9 connects the two sets of vacuum tubes 1-1 and 1-2 to form a fish-ridge-shaped solar heat collector, which is very suitable for installation on the balcony. One side. The upper and lower ends of the connection box 9 are respectively provided with an upper outlet 10 and a lower inlet 11. The heat exchange box 6 is installed on the outer wall of the bottom of the pressurized water tank 2, and an inlet 7 and an outlet 8 are opened at the bottom of the heat exchange box 6. One ends of the outlet connecting pipe 3 and the inlet connecting pipe 4 are respectively conn...

Embodiment 2

[0021] The basic structure of the split-type solar water heater in this embodiment is the same as that of the first embodiment. The difference is that the capillary action uses a non-gravity heat pipe, so the heat exchange box can be placed on the side of the water tank, and the heat pipe is in a horizontal state; The position is lower than the solar heat collection device, because an infusion pump is added to the circulation loop, which can also achieve the required heat exchange cycle; in addition, the water tank is an electric water heater tank with an electric heating rod installed therein, so the solar heating in this embodiment It forms a complementary heating system with electric heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com