Device and process method for continuously producing carbon nanotubes

A carbon nanotube and process method technology, applied in the field of nanomaterials, can solve the problems of inability to guarantee carbon nanotubes, continuous production, difficult to control fluidization state and mass transfer and heat transfer stability, etc., to improve the flexibility of operation. performance, improved utilization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The process method for continuous production of carbon nanotubes in this embodiment, wherein the preparation process of the catalyst is as follows: dissolve cobalt nitrate and nickel nitrate in water according to the molar ratio of 0.6:1, after stirring evenly, add oxidizing agent 5 times the mass of the metal salt The aluminum gel is mixed evenly, dried at 120°C for 2 hours, put into a muffle furnace and calcined at 600°C for 3 hours, ground, and sieved with 200 meshes before use.

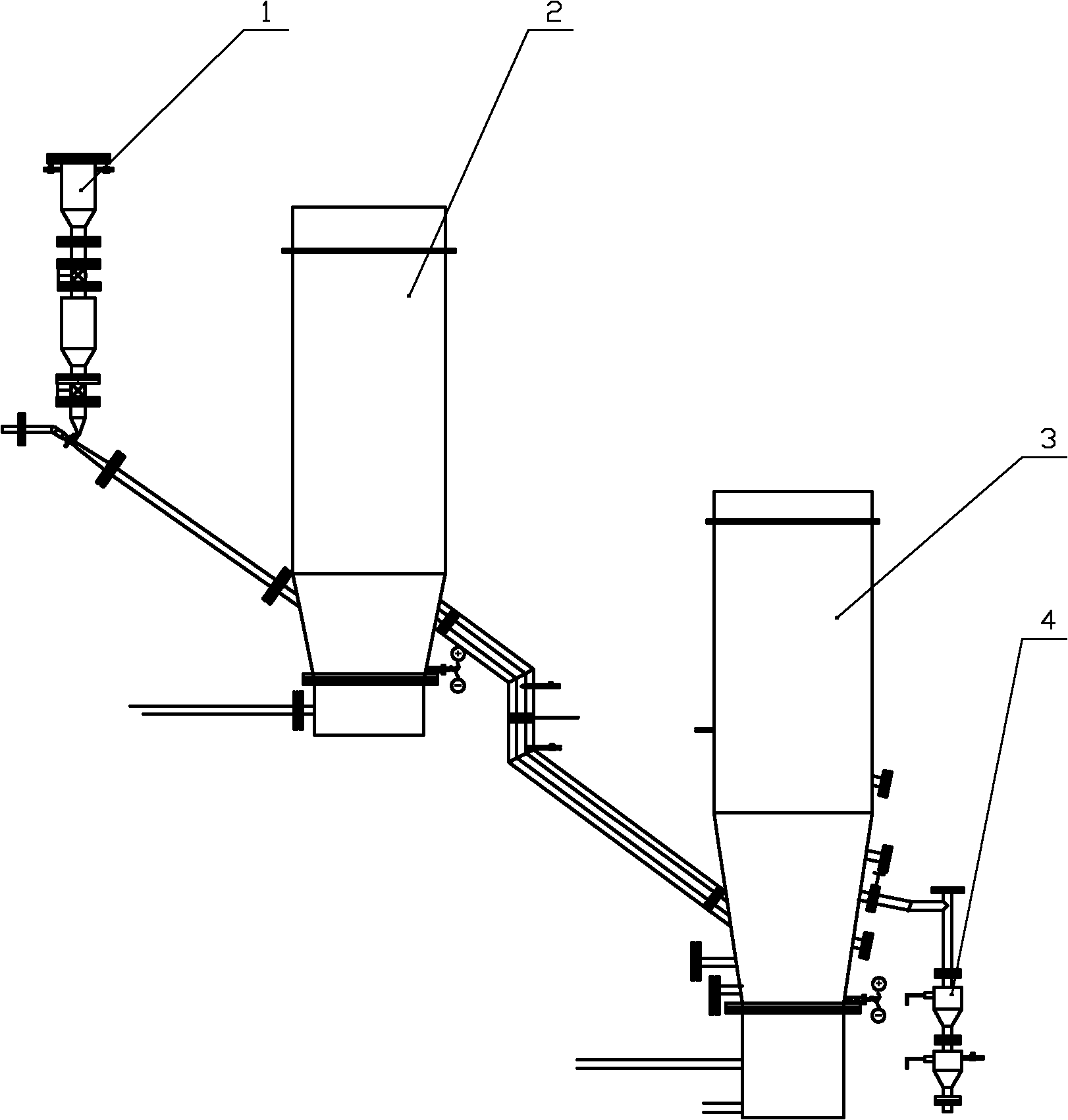

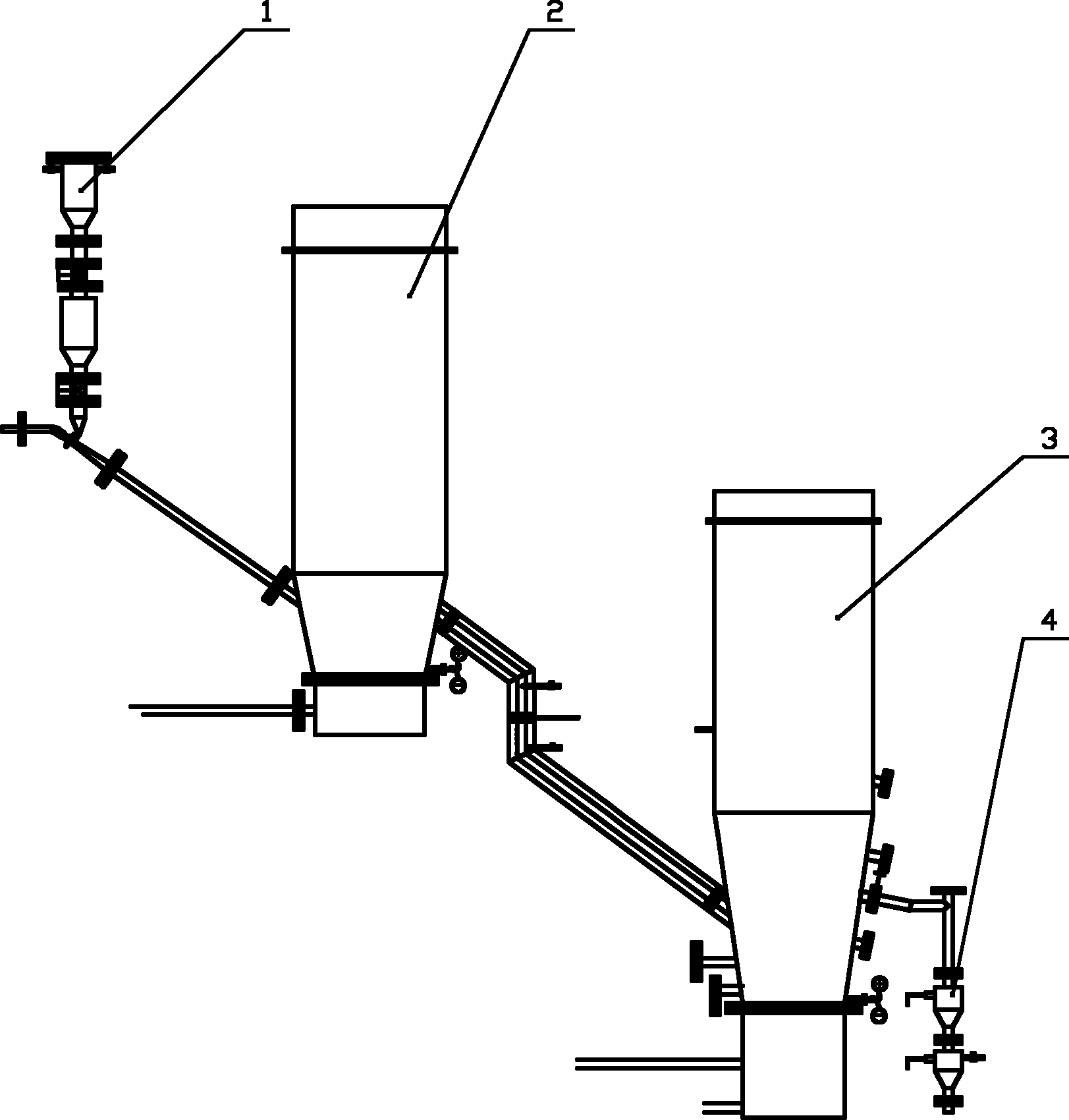

[0032] based on figure 1 As shown in the production device, the process steps of the continuous production of carbon nanotubes in this embodiment are as follows:

[0033] a. Addition of catalyst

[0034] Put the catalyst prepared above into the feeder 1, vacuum up to 600mmHg and feed nitrogen, and check the oxygen concentration. If the oxygen concentration is less than 100PPM, the system is safe.

[0035] b. Reduction catalyst

[0036] Add the catalyst into the fluidized bed of the reduc...

Embodiment 2

[0043] The process method of continuous production of carbon nanotubes in this embodiment differs from Embodiment 1 in that:

[0044] (1) In the preparation process of the catalyst, nickel nitrate is used as the metal salt; the carrier is magnesium oxide, and its dosage is twice the mass of the metal salt; the calcination temperature is 500°C.

[0045] (2) In step b, N 2 :H 2 The volume ratio=0.4:1, and the reduction time is 30min.

[0046] (3) In step c, the reaction temperature is 900°C, the carbon source gas is methane, N 2 :H 2 :CH 4 The volume ratio=0.3:0.5:1, the space velocity of the reaction process is 10000 hours ~1 , the gas superficial flow velocity is 0.5m / s, and the reaction residence time is 60min.

[0047] The parameters and properties of the obtained carbon nanotube product are as follows: purity>88%, outer diameter 15-30nm, length 10-30μm, specific surface area>120m 2 / g, black, bulk density 0.14g / cm 3 .

Embodiment 3

[0049] The process method of continuous production of carbon nanotubes in this embodiment differs from Embodiment 1 in that:

[0050] (1) In the preparation process of the catalyst, cobalt nitrate and iron nitrate are used, cobalt nitrate: iron nitrate molar ratio=1:4; the amount of carrier alumina gel is 3 times of the metal salt quality; the calcination temperature is 500°C.

[0051] (2) In step b, the reaction temperature is 450° C., and the reduction time is 180 min.

[0052] (3) In step c, the reaction temperature is 700°C, the carbon source gas is propane, N 2 :H 2 : C 3 h 6 The volume ratio=0.5:1:1, the space velocity of the reaction process is 5000 hours ~1 , The reaction residence time is 70min.

[0053] The parameters and properties of the obtained carbon nanotube product are as follows: purity>92%, outer diameter 10-35nm, length 15-30μm, specific surface area>130m 2 / g, black, bulk density 0.14g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com