Section bar

A profile, aluminum alloy profile technology, applied in the cooling/heating device of lighting device, lighting and heating equipment, electrical components, etc., can solve the problem of not being able to achieve real heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

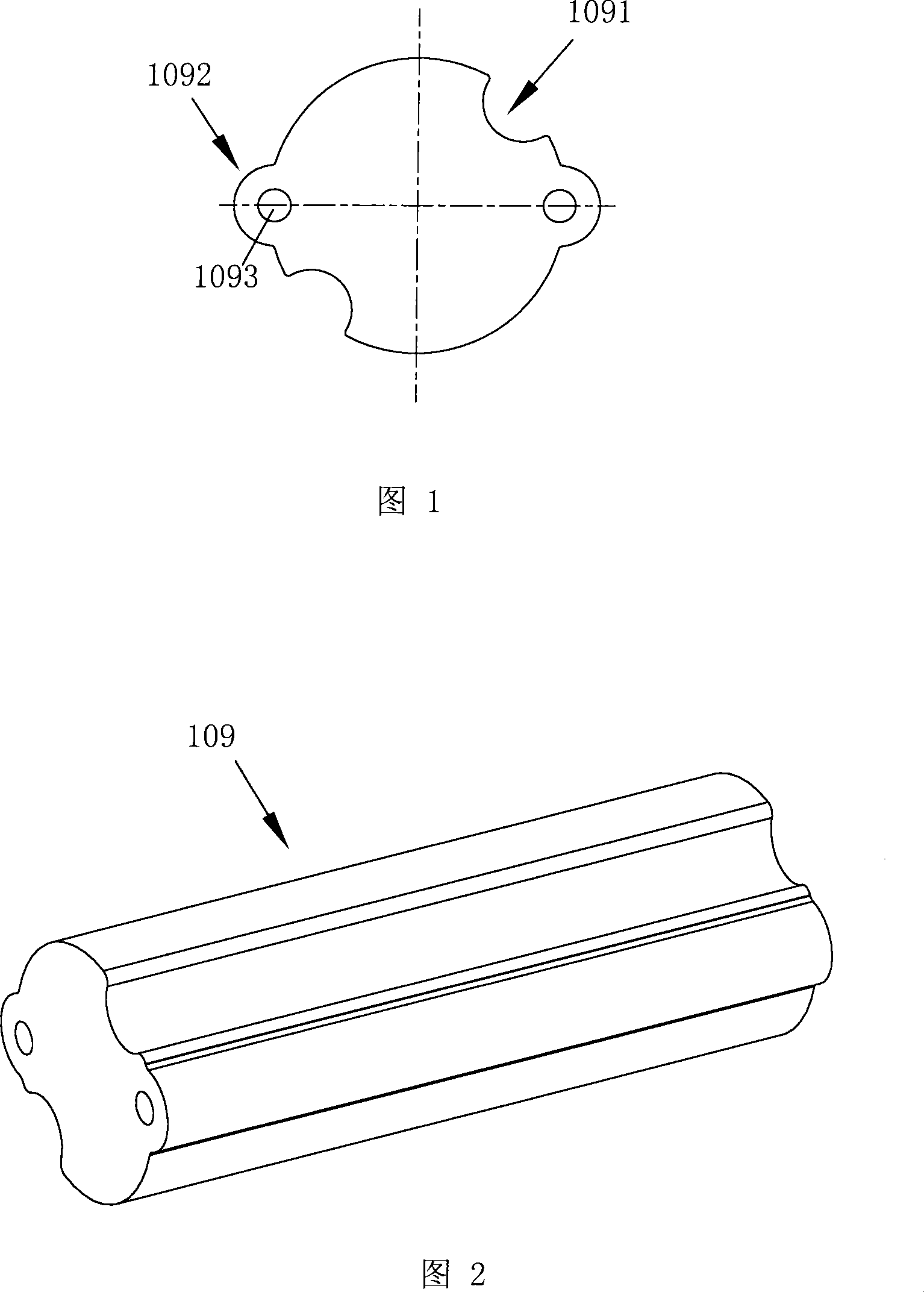

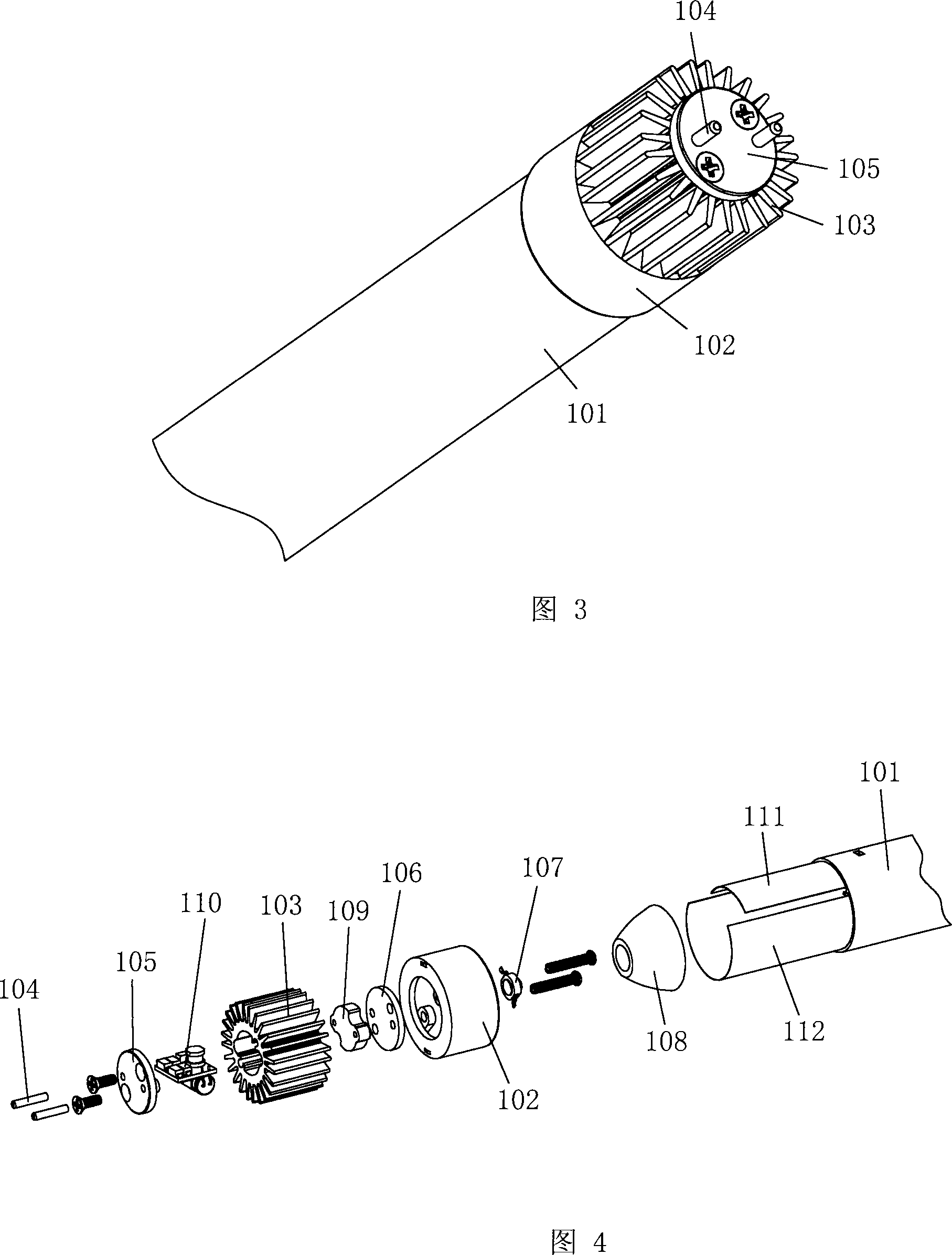

[0021] The first embodiment of the present invention is an aluminum profile. Referring to Fig. 1 and Fig. 2, along the length direction of the profile 109, different positions have the same cross-section, and the cross-section of the profile 109 consists of a circle and two Concavity 1091, two protruding positions 1092 are formed; two concavities 1091 are arranged symmetrically along a diameter of the circle, and two concavities 1091 extend along the profile length direction to form two grooves; two protruding positions 1092 are arranged symmetrically along a diameter of the circle, and two The protruding position 1092 extends along the length direction of the profile, forming two protruding ribs; the two concave positions 1091 and the two protruding positions 1092 are arranged staggered in the circumferential direction of the section; The threaded bottom hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com