Gas heat and mass transfer method based on self-microcirculation of caloric infinitesimal liquid

A heat and mass transfer, micro-element technology, applied in the field of gas heat and mass transfer, can solve the problems of difficult heat and mass transfer gradients to ensure countercurrent heat and mass transfer, high manufacturing costs, power consumption, etc., to achieve strong flexibility , good adaptability, and the effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

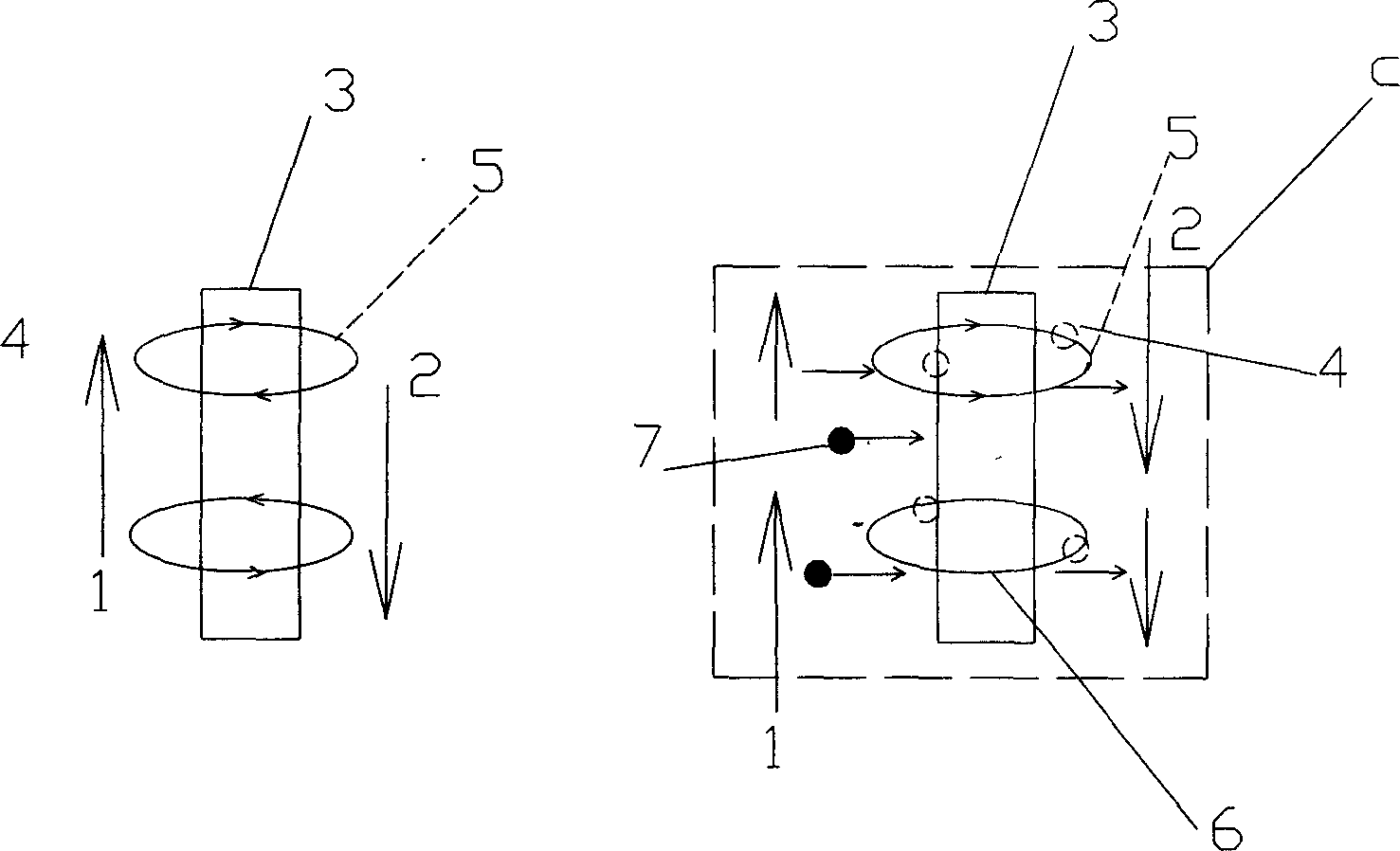

[0025] Such as figure 1 As shown, 1 and 2 are two gas microelements separated by the heat transfer wall microelement 3; 4 is the liquid microelement kept on the heat transfer wall microelement and can permeate and disperse in the heat transfer wall; 5 and 6 are Thermal mass microelement circulation, where 5 is clockwise, 6 is counterclockwise, 7 is selectively absorbed gas, microelement C is thermal mass microelement. The shapes shown are illustrative only, and their cycles may appear to be irregular or random in practice.

[0026] Assuming that the direction of mass transfer and heat transfer is from side 1 to side 2, the liquid 4 receives heat on the side of gas 1 and (or) absorbs part of the gas at the same time, through the microcirculation 5 and 6 of the liquid itself, on the other side, that is, the side of gas 2 release of heat and / or gas.

[0027] Assuming that the direction of mass transfer points from side 1 to side 2, and the direction of heat transfer from side 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com