Internal heating type anti-freezing cable for severe cold regions and anti-freezing method thereof

It is an internal heating type and regional technology, which is applied in the direction of insulated cables, cables, circuits, etc., and can solve the problems of ordinary cables, such as hard cables, cable damage, brittle cracks, etc., and achieve the effect of avoiding burning and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

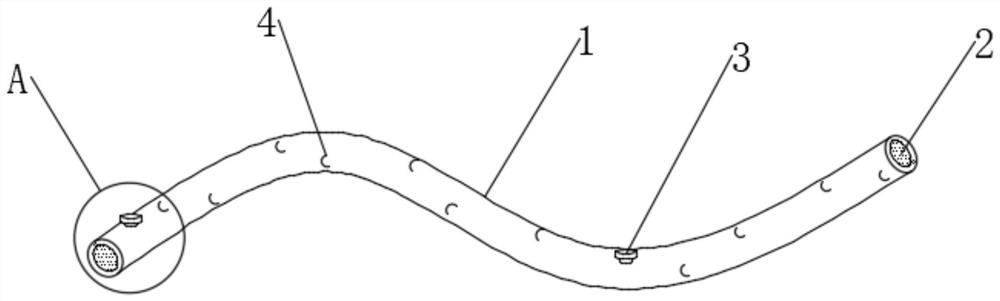

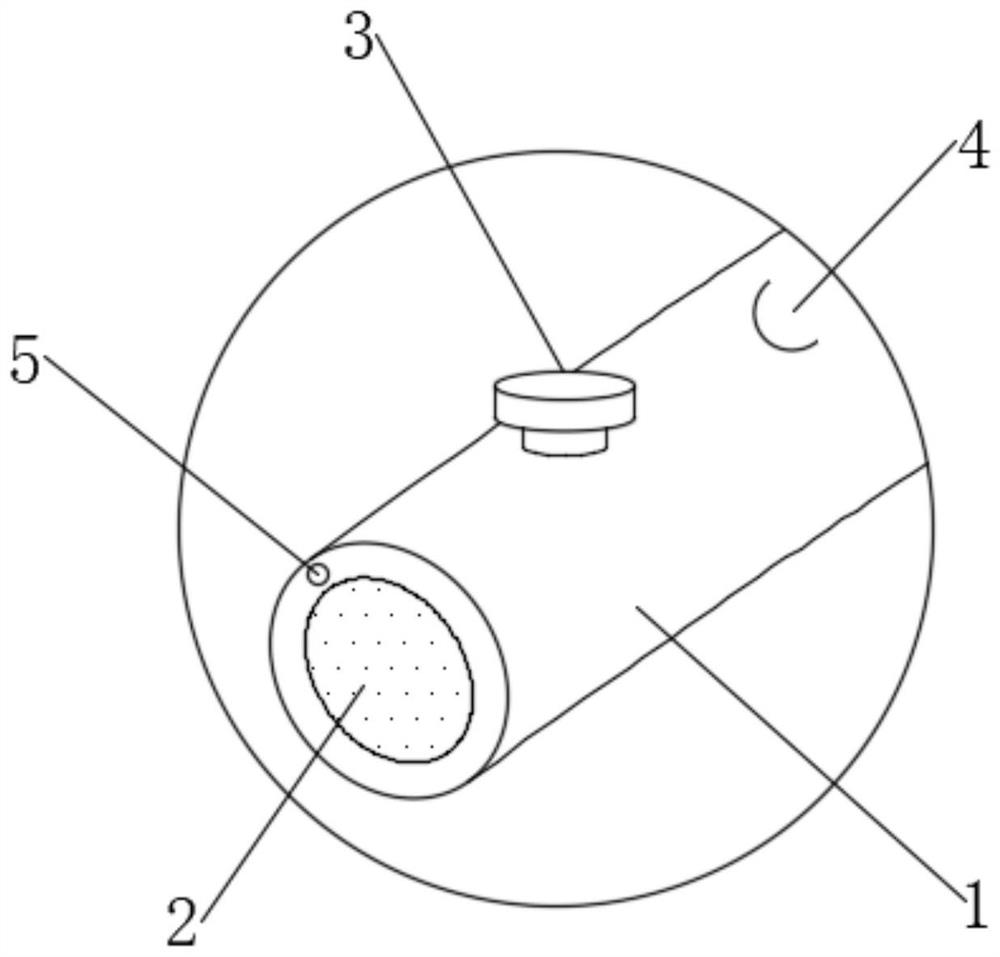

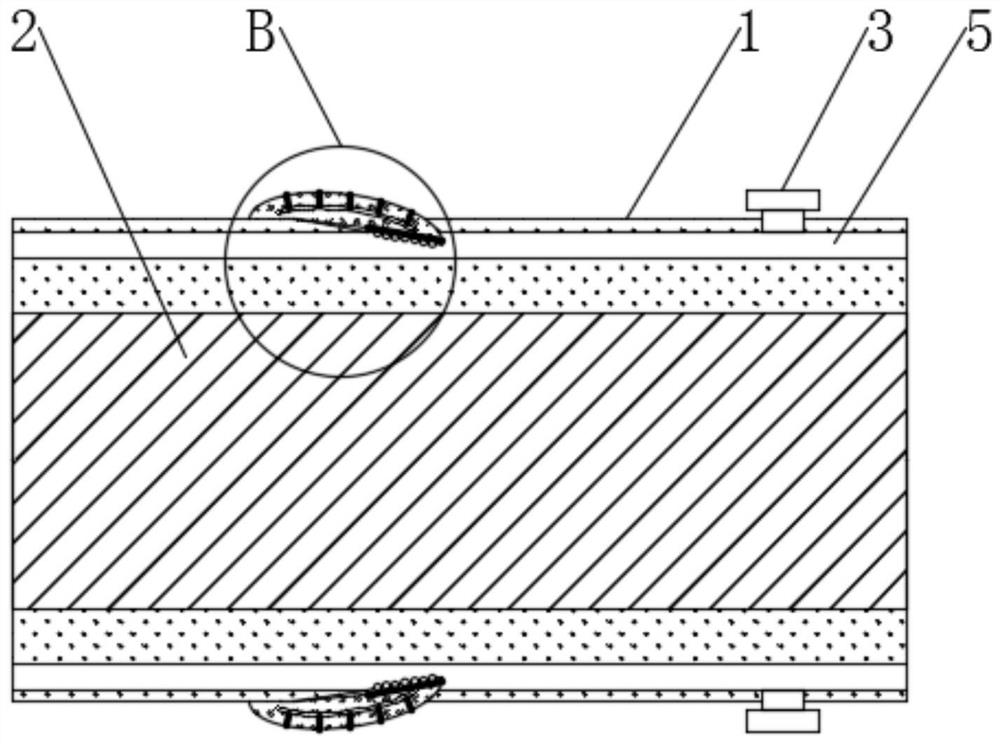

[0049] see Figure 1-2 , an internal heating type antifreeze cable for severe cold regions, comprising an internal heating type antifreeze layer 1 and a cable core 2 embedded in the internal heating type antifreeze layer 1, the internal heating type antifreeze layer 1 is provided with a supplementary hole 5, There are several evenly distributed inflatable heads 3 connected to the internal heating antifreeze layer 1, and the inflatable heads 3 are connected to the supplementary holes 5, and an inflatable head 3 is set at a certain distance, which can avoid the difficulty of inflating caused by too long cables , There are a plurality of evenly distributed cold-sensing outer scales 4 between the inflatable heads 3 .

[0050] see Figure 3-4 The cold-sensing outer scales 4 include an obliquely inserted thermal insulation sheet 41 and a pull-change cold-shrinkable mandrel 42 embedded in the obliquely-inserted thermal insulation sheet 41, and the pull-variable cold-shrinkable mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com