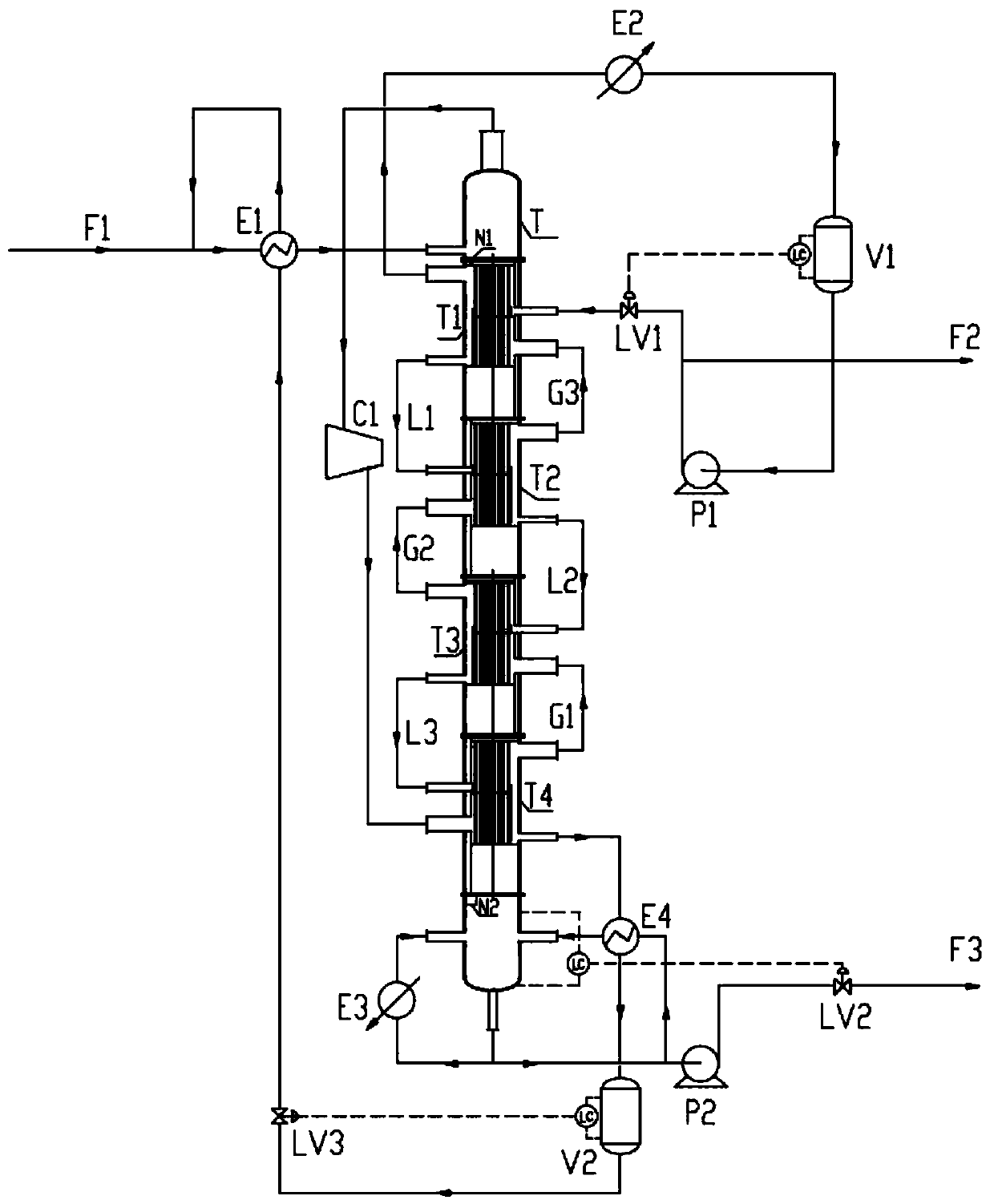

Matching device and method of novel rectifying tower system with internal energy integration

A technology of internal energy and rectification tower, which is applied in the field of rectification tower, can solve the problems of high energy consumption, close boiling point of rectification separation, high operating cost, etc., and achieve the effect of increasing heat exchange area, saving energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

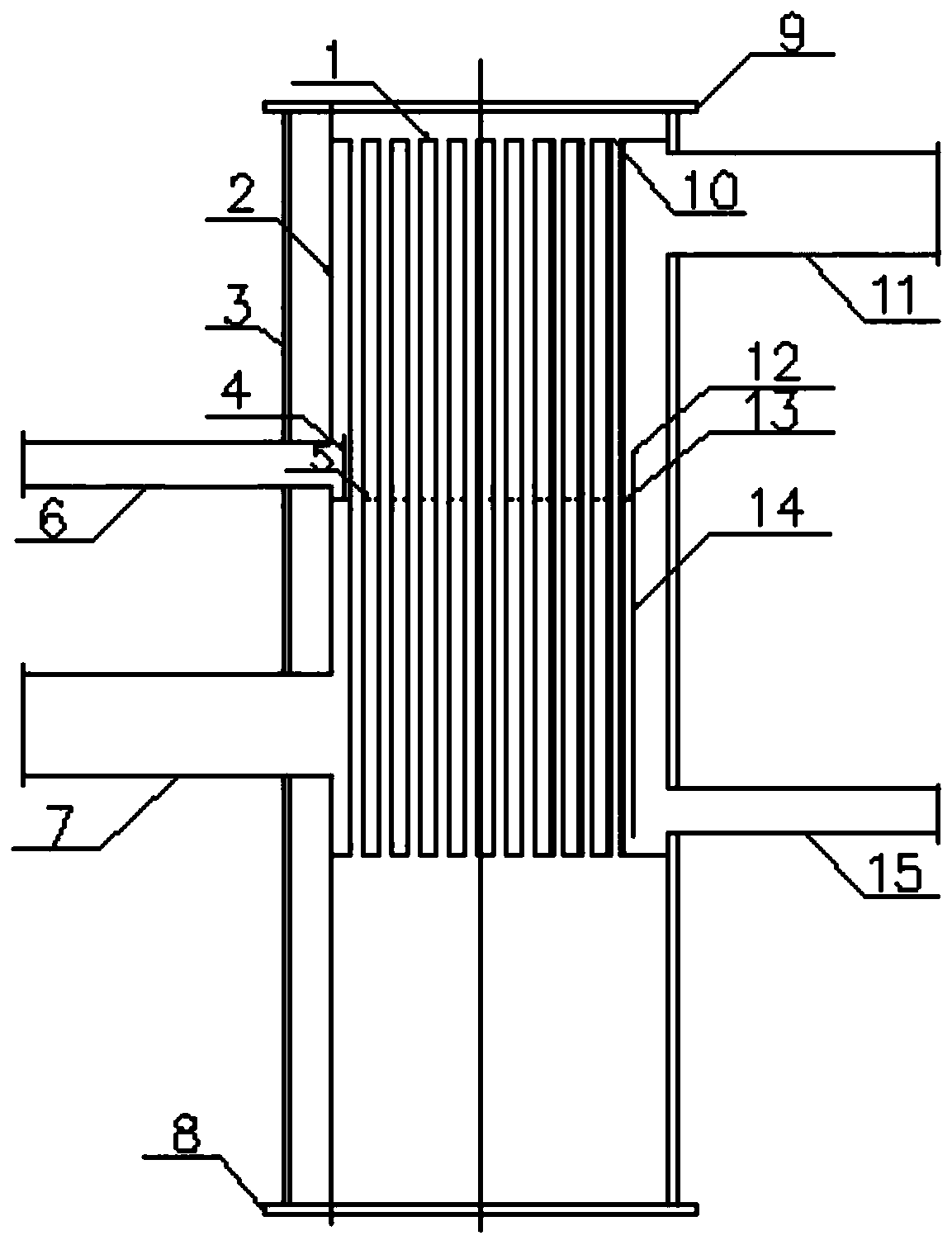

Method used

Image

Examples

Embodiment 1

[0034] The rectification tower separates the BTX substance system benzene and toluene, adopts the process described in the present invention, and the top feed of the rectification tower stripping section with internal energy integration is characterized by 100kg / hr of benzene and toluene feed mass flow rate, and 100kg / hr of toluene feed mass flow rate 100kg / hr, saturated liquid feed, the feed pressure is 1 bar, the number of theoretical plates in the rectification section is 10, the working pressure is 4 bar, the working pressure of the stripping section is 1 bar, the working pressure is 1 bar, and the feeding position is the internal energy integration refining The first tray in the stripping section of the distillation tower has a reflux ratio of 1.16, a gas temperature at the top of the tower of 90°C, and after compression, its pressure is 4 bar, and the outlet temperature of the compressor is 145°C. When the device starts up, the heat load of the heat exchanger at the botto...

Embodiment 2

[0036] Overall flow process is identical with embodiment 1, but difference is: benzene and toluene feed mass flow rate 1000 kg / hr, toluene feed mass flow rate 1000kg / hr, saturated liquid feed, feed pressure is 1bar, rectifying section theory The number of plates is 10, the working pressure is 5 bar, the working pressure of the stripping section is 1 bar, the working pressure is 1 bar, the feed position is the first tray of the stripping section of the internal energy integrated rectification tower, the reflux ratio is 0.986, and the gas temperature at the top of the tower is After compression, its pressure is 5bar, and the outlet temperature of the compressor is 155°C. When the device starts up, the heat load of the heat exchanger at the bottom of the tower is 145KW / hr, the power of the compressor is 105.2kw, and the latent heat of steam condensation at the top of the tower is 120.6KW. The heat flux exchanged by each theoretical plate is 730.86kcal / hr.m 2 .k Under the same se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com