Efficient liquid distributing pipe

A technology of liquid distribution pipes and distribution pipes, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor mass transfer and heat transfer effects, insufficient vapor-liquid contact, etc. Achieve the effects of mass transfer and heat transfer, increase the area, and improve the effect of mass and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

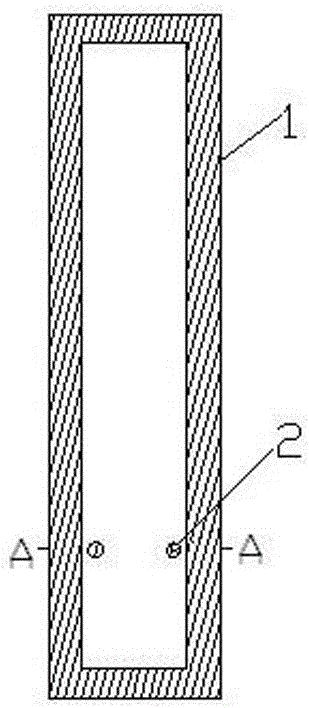

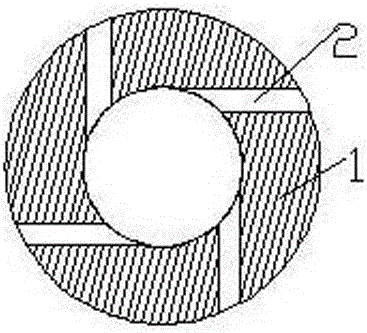

[0008] exist Figure 1-2 Among them, it includes a distribution pipe 1, and four round holes 2 with a diameter of 2.5 mm are drilled equidistantly on the same horizontal line in the lower part of the pipe wall of the distribution pipe 1. The round holes 2 pass from the outside of the pipe to the inside of the pipe, so that the liquid is spiral Into the tube, and can be distributed along the inner wall of the tube in a film shape, the direction of the round hole 2 is tangent to the distribution tube 1, and the four round holes 2 are all at the same elevation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com