Method and thermoforming apparatus for producing forged steel sheet forming components

A forming component and thermoforming technology, which is applied in the field of manufacturing forged steel plate forming components, can solve the problems of cost consumption and economic disadvantages, and achieve the effects of reducing energy consumption, reducing sensitivity and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

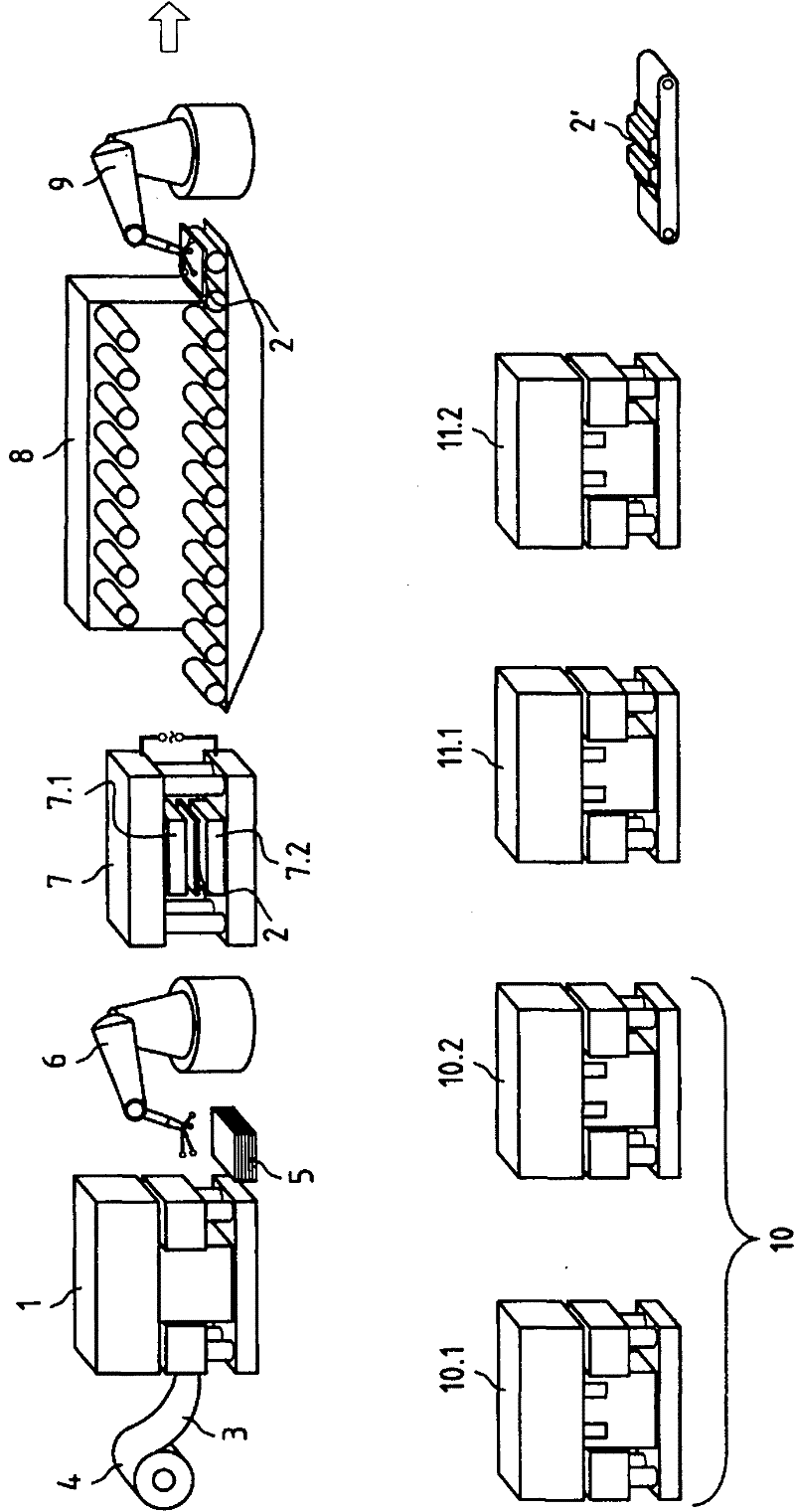

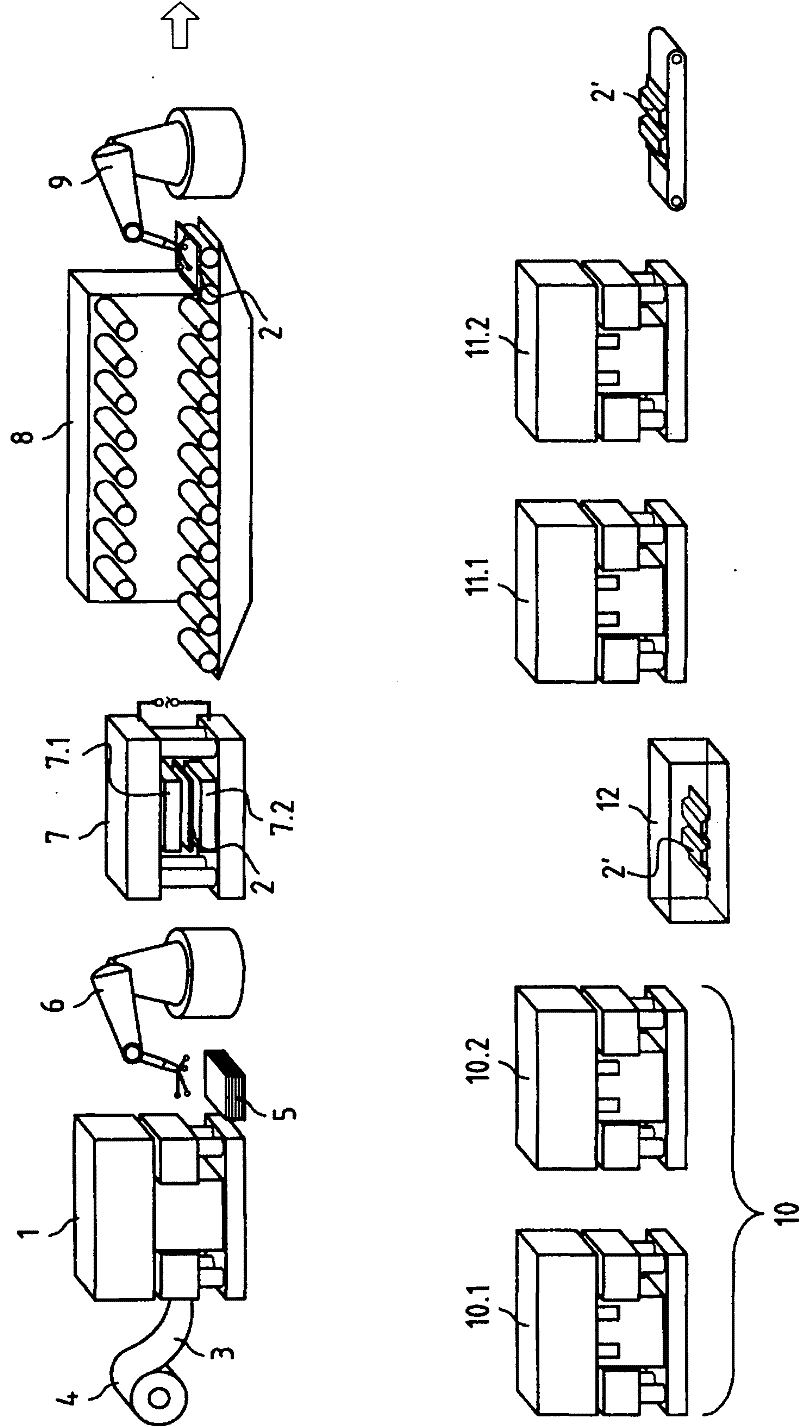

[0033] figure 1 The shown thermoforming device is used for the production of forged sheet steel profiled components 2 ′, such as chassis transmission rods or side impact brackets for motor vehicle doors. Other examples of such profiled components are also bend brackets, B-pillars, a-pillars and roof frames. The hot forming device comprises a punching machine 1 for cutting a steel strip 3 into slabs 2 . The steel strip 3 is made of manganese-boron steel, preferably manganese-boron steel (AlSi-22MnB5) pre-diffused by continuous annealing. The steel strip is introduced as a coil 4 by the unwinding device of the punching machine 1 which operates with a high number of strokes. placing the slab 2 on a stack 5, which serves as a buffer, transferring the slab to a heating device 7 by means of a robot 6 or other suitable transfer means, and placing the slab into this heating device, Then it reaches the continuous furnace 8.

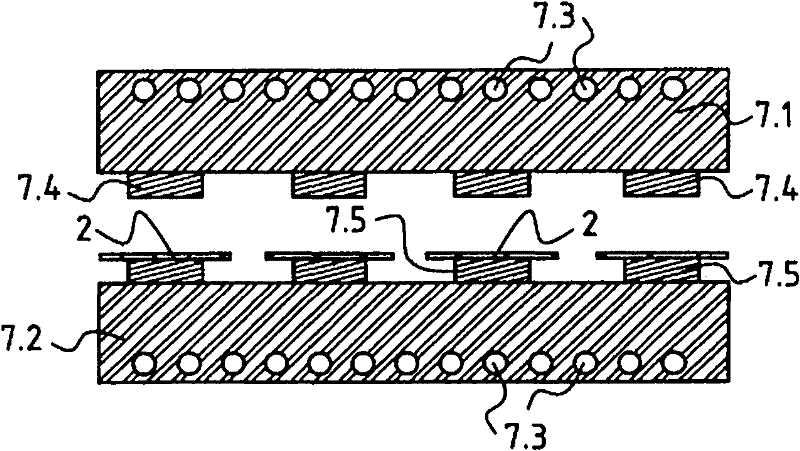

[0034] The heating device 7 according to the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com