Aluminium-water reaction high-energy system apparatus

A system device, a technology for the reaction of aluminum water, applied in the field of energy and power, can solve the problems of difficult reaction start, complicated process, difficult to popularize, etc., and achieves the effects of good comprehensive effect, convenient operation, and simple materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

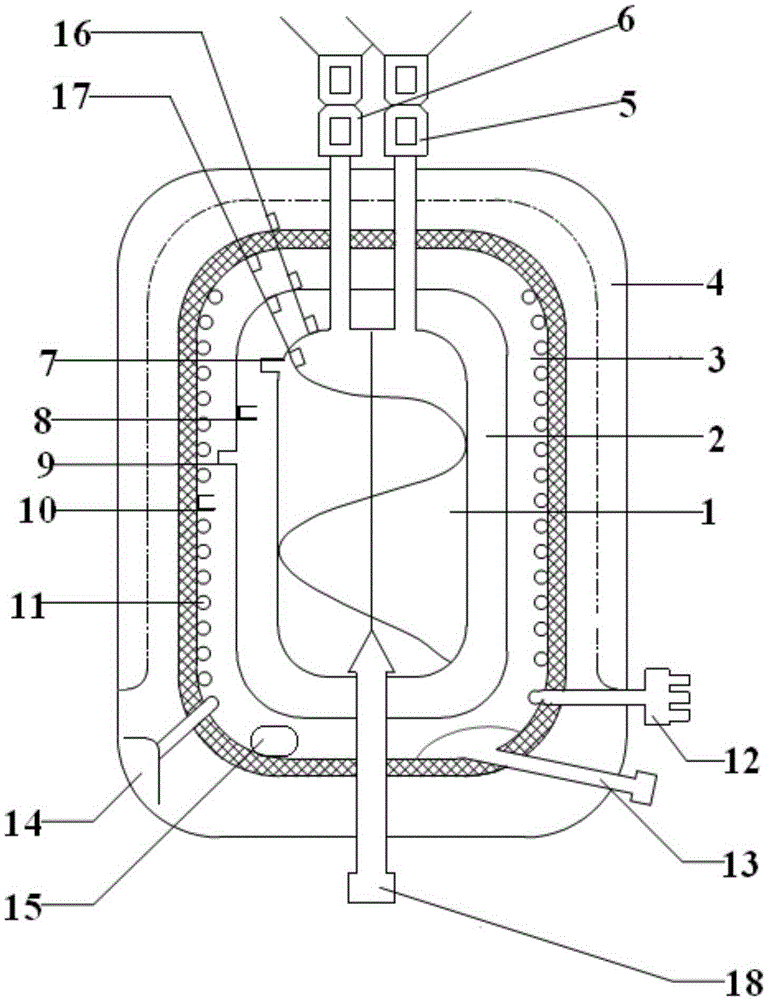

[0020] The structure of the aluminum water reaction high-energy system device provided in this embodiment is as follows: figure 1 As shown, it includes a vortex reaction chamber 1, and the outside of the vortex reaction chamber 1 is sequentially provided with a first combustion chamber 2, a second combustion chamber 3 and a thermal power generation system 4; the vortex reaction chamber 1, the first The combustion chamber 2, the second combustion chamber 3 and the thermal power generation system 4 together form a four-layer concentric sleeve kettle; the walls of the vortex reaction chamber 1 and the first combustion chamber 2 are made of high-strength 304 stainless steel or 314 stainless steel; The wall of the second combustion chamber 3 is made of S31603 stainless steel and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com