Low temperature heat tube for thermal switch

A heat switch and heat pipe technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of inequalities and achieve the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

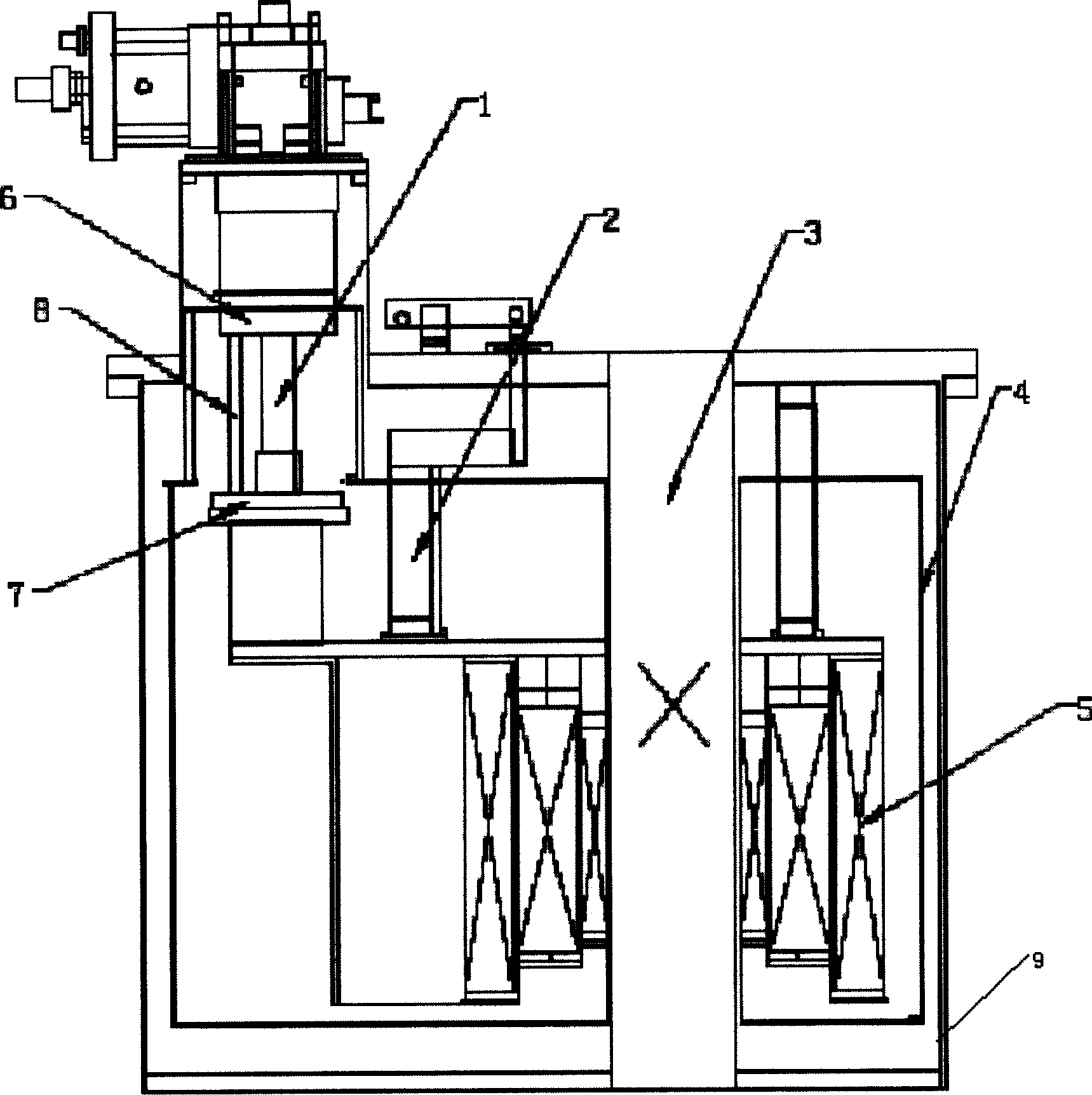

[0018] Such as figure 1 As shown, when the heat pipe is installed in the embodiment of the present invention, copper blocks are drawn from the primary and secondary cold heads. The copper blocks are made of high-purity copper, and the thickness of the plates is about 3-4mm. The surface in contact between the copper block and the heat pipe should be very smooth. The length of the heat pipe can be determined according to the distance between the primary and secondary cold heads of the refrigerator. For example, the distance between the primary and secondary cold heads of Sumitomo Electric’s GM refrigerator is about 23.6-24cm , the length of the heat pipe must be less than the distance between the primary and secondary cold heads, and sometimes the length of the heat pipe is related to the structure of the cryogenic container and the position of the magnet.

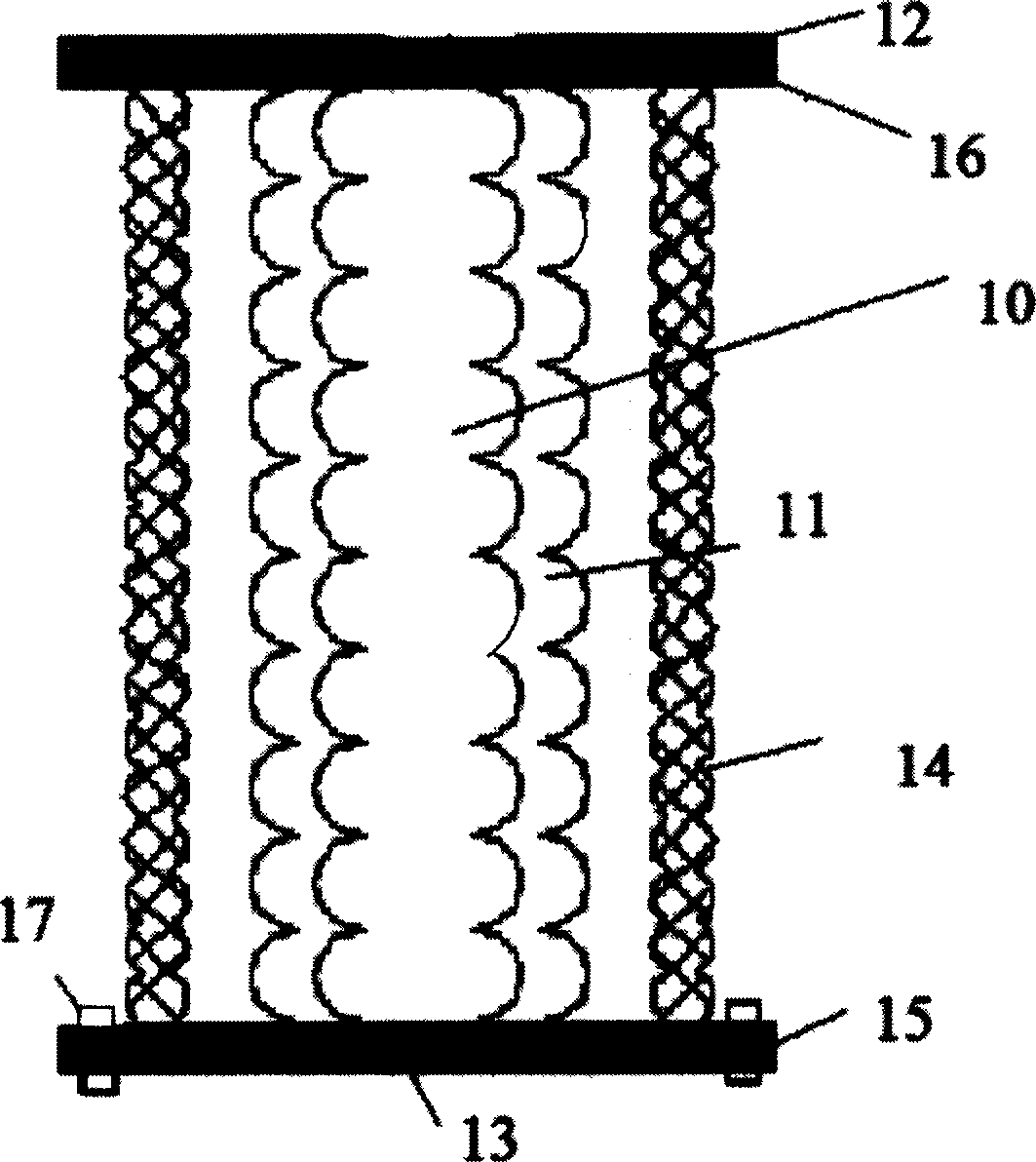

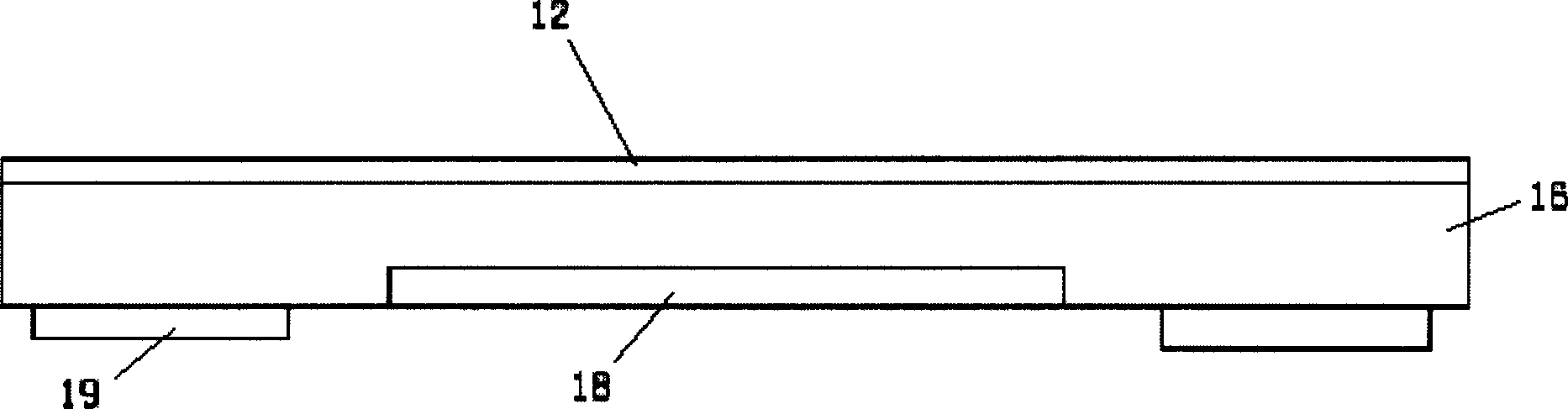

[0019] Such as figure 2 As shown, an indium film with a thickness of about 0.5-1 mm is placed on the copper blocks 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com