Garbage incineration device and method

A waste incineration and equipment technology, applied in the field of waste treatment equipment, can solve the problems of insufficient waste incineration, good waste incineration effect, poor incineration effect, etc., achieve good waste incineration effect, convenient and reliable ignition, and speed up waste incineration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

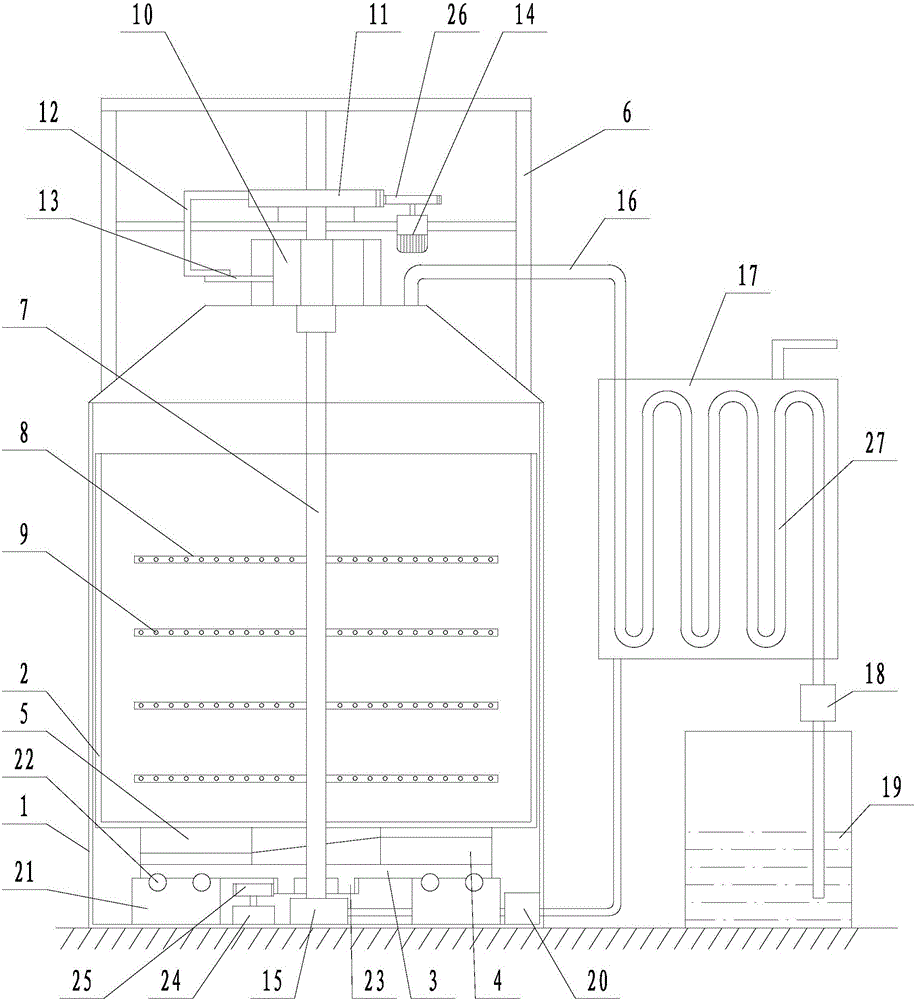

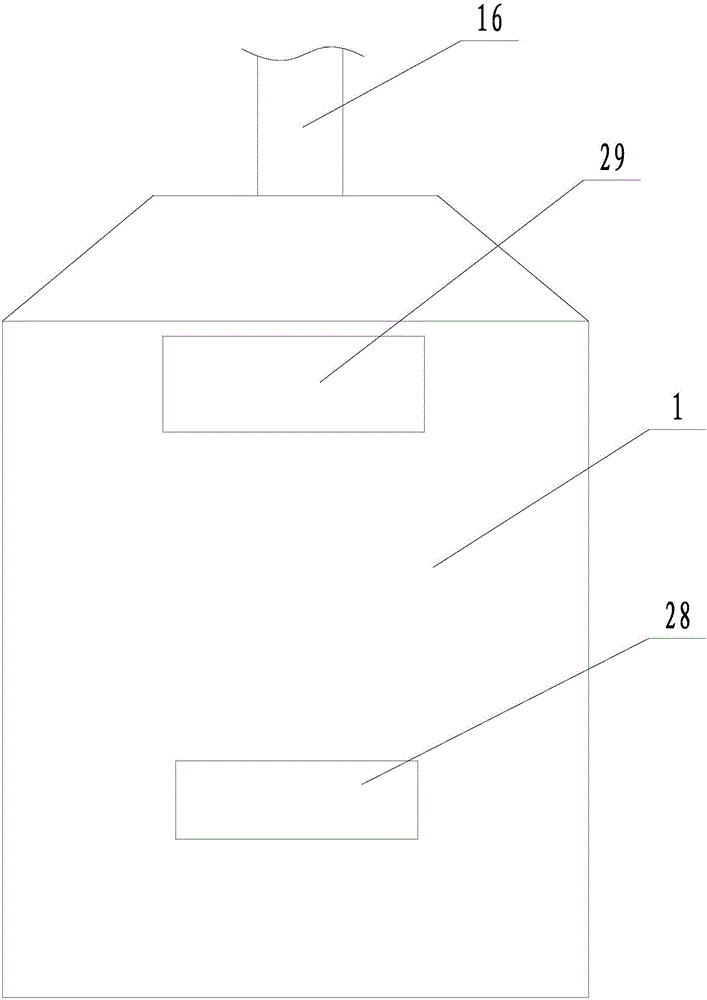

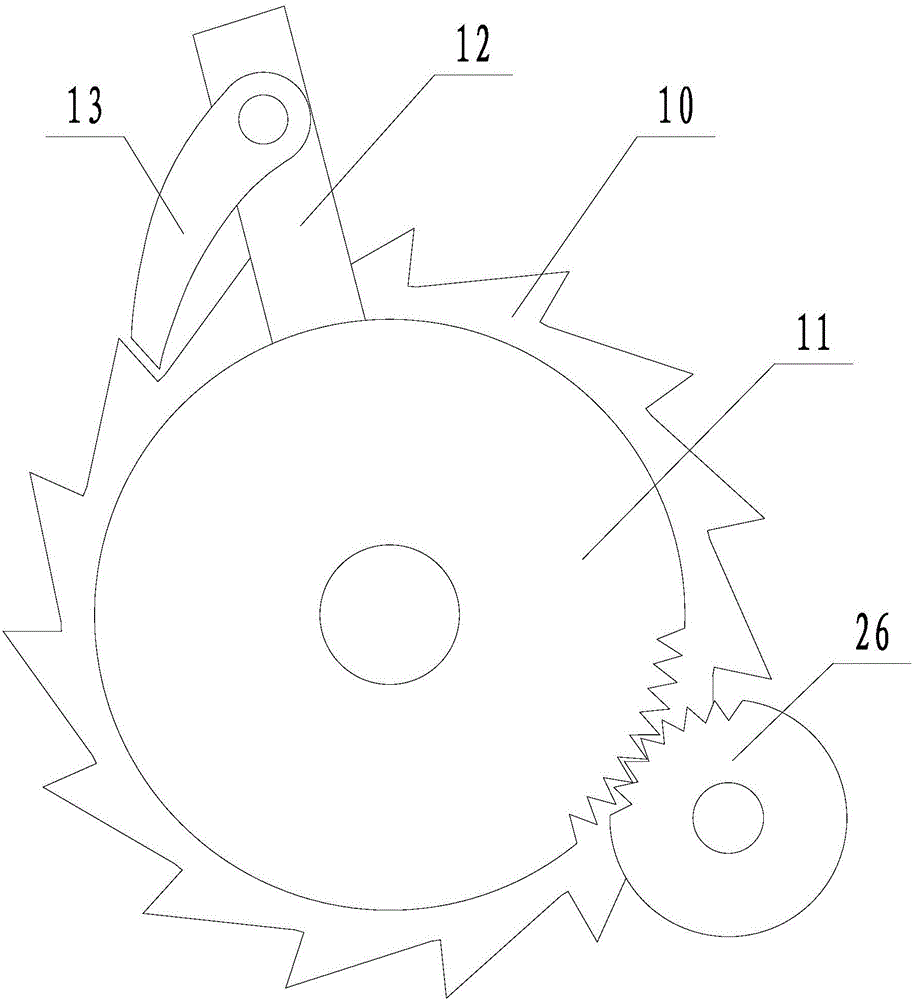

[0023] Embodiment: a kind of garbage incineration equipment (see attached Figures 1 to 3 ), including an incinerator 1, an incinerator 2 is sleeved in the incinerator, an ash outlet window 28 is provided on the side wall of the incinerator near the lower end, and an ash outlet window 29 is provided on the side wall of the incinerator near the upper end. The ash outlet window and the discharge window on the outer wall of the incinerator are all connected with windows and doors with up and down sliding switches. A turntable 3 is installed on the inner bottom of the incinerator, and three arc-shaped wedge-shaped protrusions 4 are evenly distributed on the upper surface of the turntable. The upper surface of the wedge-shaped protrusions is inclined upwards along the clockwise direction. It is fitted with three arc-shaped abutting convex strips 5, and the lower surface of the abutting convex strips is inclined downward along the counterclockwise direction; a support ring 21 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com