Special waste treatment equipment for veterinarian

A technology for processing equipment and waste, which is applied in the field of waste treatment, can solve the problems of less combustion accelerant, affecting the effect of waste incineration, and the distance of combustion accelerant cannot be guaranteed, so as to ensure the treatment effect, ensure the combustion effect, and improve The effect of mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

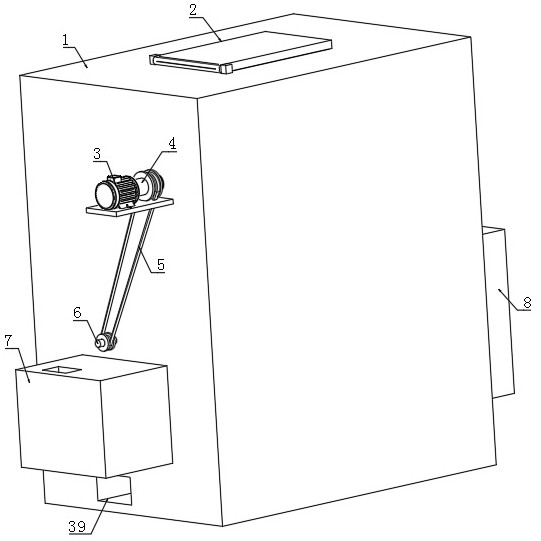

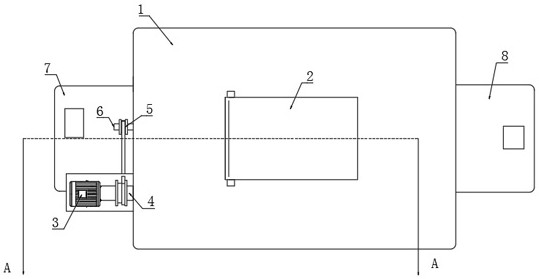

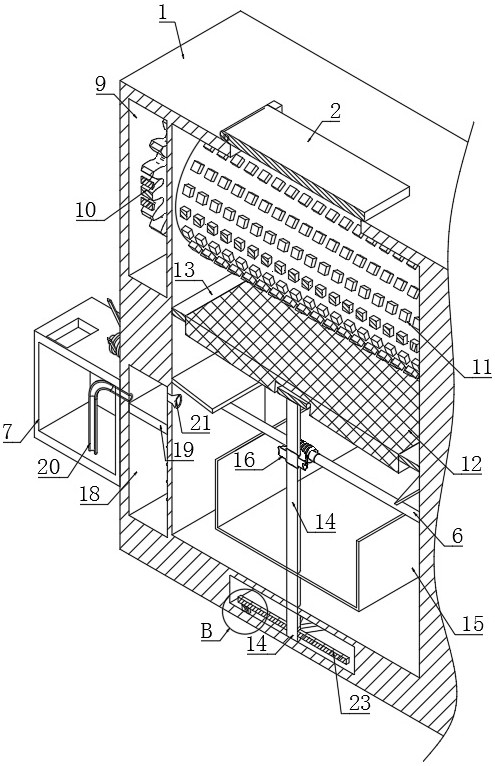

[0017] The box body 1 is provided with a transmission cavity 9, and the transmission cavity 9 is provided with two first rotating rods 4 horizontally. The right ends of the first rotating rods 4 both extend into the treatment chamber and are fixedly connected with the grinding rollers 11 . The outer walls of the two first rotating rods 4 are fixedly connected with mutually matched rotating gears 10 , and the two rotating gears 10 are meshed with each other. , so that the operation of the driving motor 3 makes the rotation directions of the two grinding rollers 11 opposite, and the left end of the first rotating rod 4 on the front side extends to the outside and is fixedly connected with the end of the output shaft of the driving motor 3 .

[0018] Among them, the inner walls of the left and right sides of the treatment chamber are fixedly connected with telescopic plates 13, and the treatment chamber is provided with a screen mesh 12. The telescopic ends of the two telescopic p...

Embodiment 2

[0024] In this embodiment, when the piston 19 moves up, the outside air will enter the bottom space of the reciprocating chamber 18 at this time. When the piston 19 moves down, the gas in the bottom space of the reciprocating chamber 18 enters through the air inlet pipe 37 to the bottom of the reciprocating chamber 18. In the top space of the rectangular box 34, since the exhaust port 41 is hermetically sealed, the gas in the top space of the rectangular box 34 increases, and the air pressure increases, so that the conductive plate 36 moves down, so that the resistance bar 35 is connected to the circuit The resistance decreases, the current passing through the two electromagnets 33 increases, and the repulsion force of the two electromagnets 33 to the plurality of stirring rods 32 increases;

[0025] Compared with the prior art, through the arrangement of the electromagnet 33 and the plurality of stirring rods 32, the waste particles will be constantly turned over during the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com