Antistatic smokeless sulfur-free firecracker nitrate agent and preparation method thereof

A technology of antistatic agent and firecracker nitrate, applied in explosives processing equipment, nitrated acyclic/alicyclic/heterocyclic amine explosive composition, explosives, etc., can solve problems such as smoke pollution, improve mechanical properties, and make raw materials easy to use The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

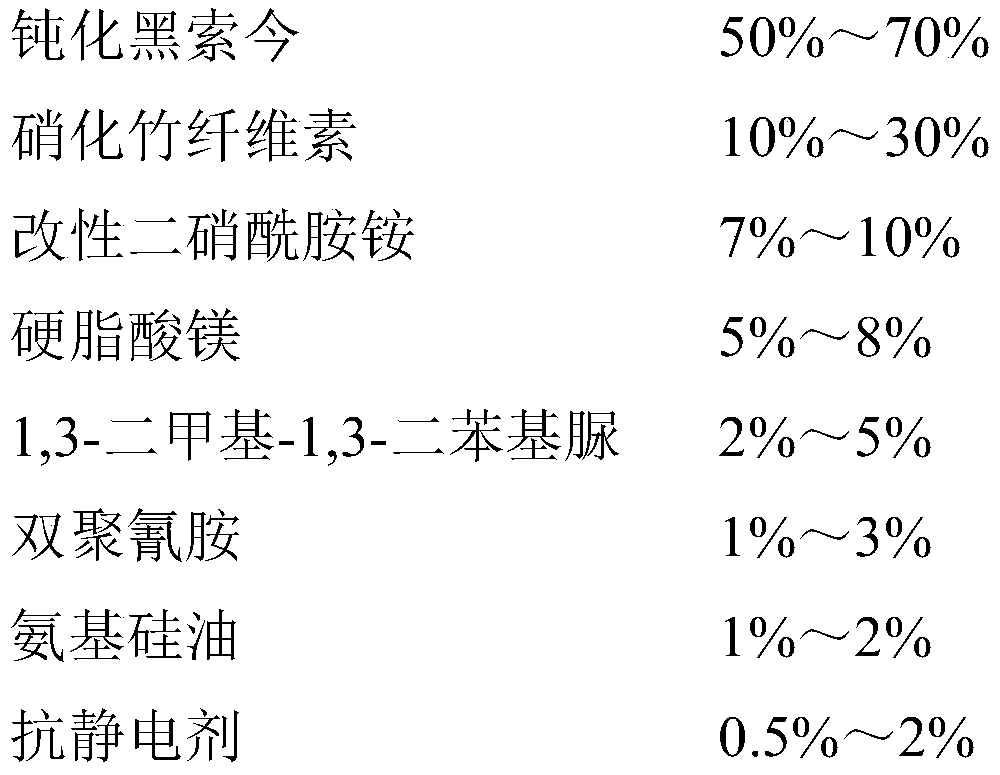

[0027] An antistatic smokeless and sulfur-free firecracker nitrate agent, the mass percentage of each component is as follows:

[0028]

[0029] Take 55.62g of nitrobamboo cellulose powder and divide it into two groups, A and B, wherein 15.62g of group A and 40g of group B, and dissolve the nitrobamboo cellulose powder of group A in 156.2g of ethyl acetate, and stir under ultrasonic dispersion conditions After 2.5 hours, continue to stir, add 2.72g of dicyandiamide, 10.47g of 1,3-dimethyl-1,3-diphenylurea and 16.80g of magnesium stearate, and stir evenly to obtain bamboo nitrate Cellulose mixed sol;

[0030] Add 1.91g of α-hydroxyethylamine phosphate to 19.1g of acetone, stir for 70 minutes in an ultrasonic state, and then put it into a spray gun to prepare an antistatic agent spray;

[0031] In the state of stirring and ultrasonic dispersion, add 123.74g of passivated hexogen, 21.90g of modified ammonium dinitramide and group B nitrobamboo cellulose into the nitrocellulos...

Embodiment 2

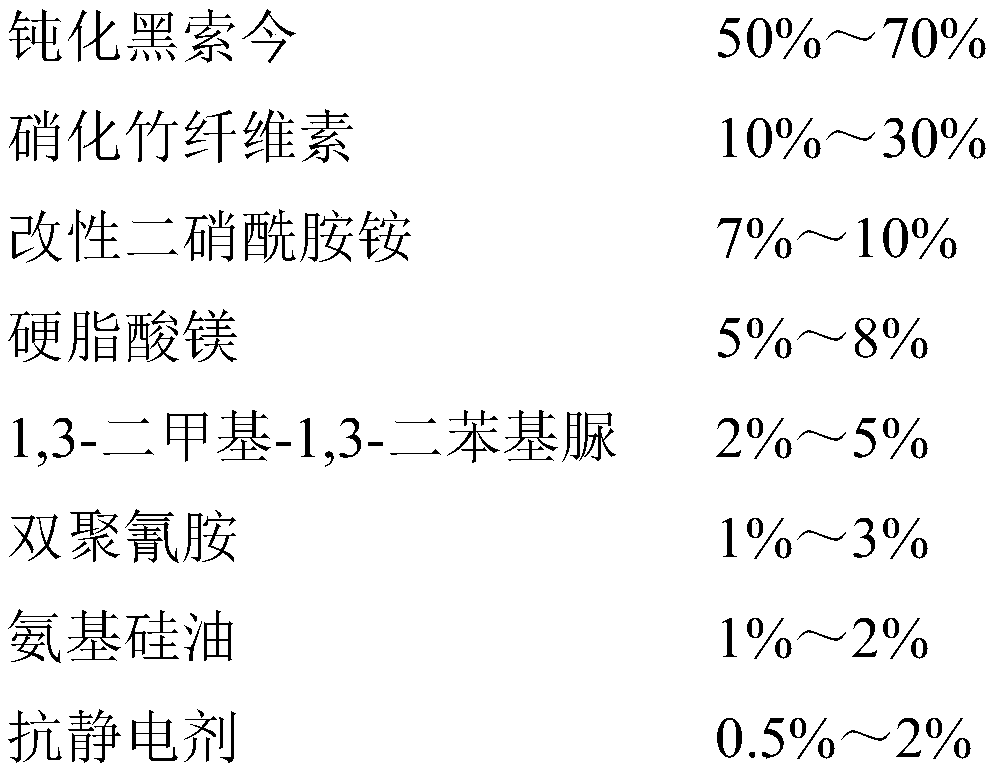

[0036] An antistatic smokeless and sulfur-free firecracker nitrate agent, the mass percentage of each component is as follows:

[0037]

[0038]

[0039] Take 11.12kg of nitrobamboo cellulose powder and divide it into two groups, A and B, wherein 2.12kg of group A and 9kg of group B, and dissolve the nitrobamboo cellulose powder of group A in 21.2kg of ethyl acetate, and stir under the condition of ultrasonic dispersion 3 hours, then continue to stir, add 0.76kg of dicyandiamide, 1.38kg of 1,3-dimethyl-1,3-diphenylurea and 3.68kg of magnesium stearate, stir evenly, and obtain bamboo nitrate Cellulose mixed sol;

[0040]0.78kg of stearamidopropyl hydroxyethyl quaternary ammonium nitrate isopropyl was added to 7.8kg of acetone, stirred for 80 minutes in an ultrasonic state, and then packed into a spray gun to obtain an antistatic agent spray liquid;

[0041] In the state of stirring and ultrasonic dispersion, add 40.82kg of passivated hexogen, 4.62kg of modified ammonium ...

Embodiment 3

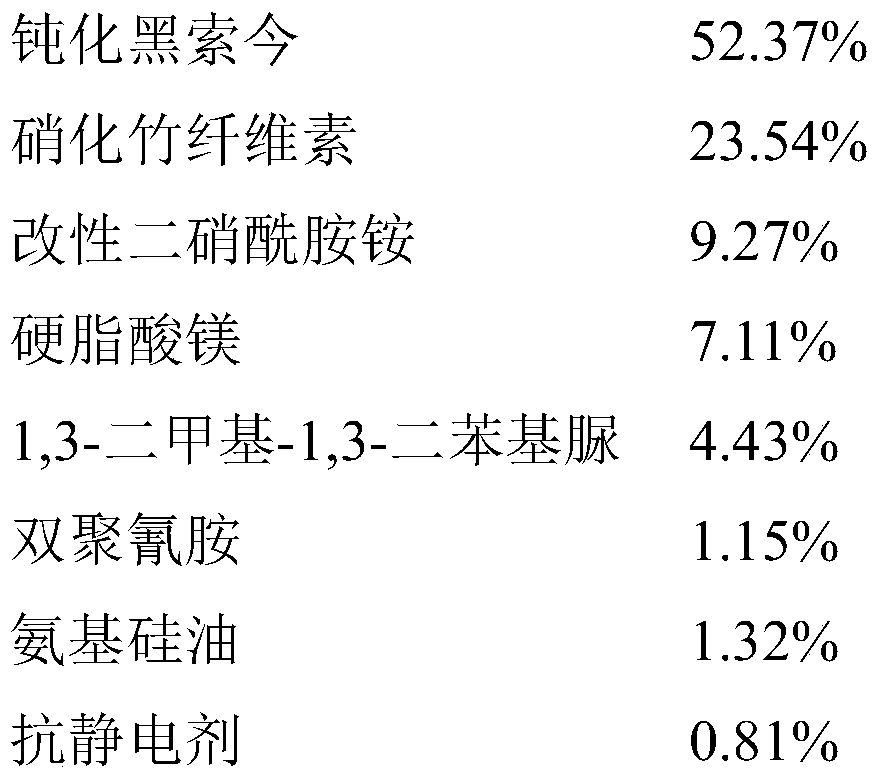

[0046] An antistatic smokeless and sulfur-free firecracker nitrate agent, the mass percentage of each component is as follows:

[0047]

[0048] Take 23.73kg of nitrobamboo cellulose powder and divide it into two groups, A and B, wherein group A is 8.73kg and group B is 15kg. Dissolve the nitrobamboo cellulose powder in group A in 87.3kg of ethyl acetate and stir under ultrasonic dispersion conditions 3 hours, then continue to stir, add 2.59kg of dicyandiamide, 3.62kg of 1,3-dimethyl-1,3-diphenylurea and 7.12kg of magnesium stearate, and stir evenly to obtain bamboo nitrate Cellulose mixed sol;

[0049] 1.70 kg of alkyl dicarboxymethyl betaine was added to 17 kg of acetone, stirred for 90 minutes in an ultrasonic state, and then loaded into a spray gun to obtain an antistatic agent spray liquid;

[0050] In the state of stirring and ultrasonic dispersion, add 62.18kg of passivated hexogen, 9.44kg of modified ammonium dinitramide and group B nitrobamboo cellulose into the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com