Preparation method of aeration combustion-supporting biomass briquette

A technology for biomass fuel and briquette fuel, which is applied in the direction of biofuel and waste fuel, can solve the problems of affecting the compaction density of biomass fuel, the aging and decay of biomass fuel, and the difficulty of lamination processing, so as to save the cost of raw materials, The effect of increasing compaction density and improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

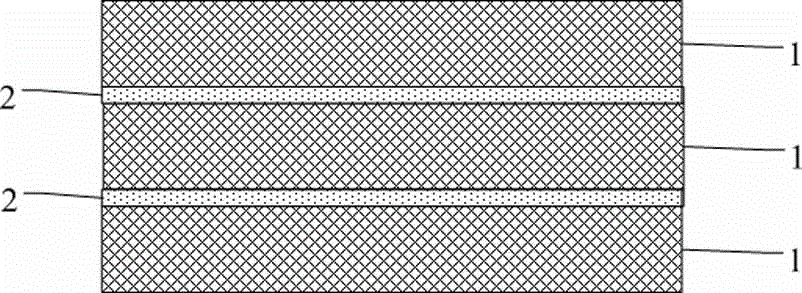

Image

Examples

Embodiment 1

[0028]A method for preparing aeration and combustion-supporting biomass briquettes, comprising the following steps: the first step, the preparation of a biomass fuel substrate, crushing and pre-drying cellulose-based biomass debris, and adding an amount equivalent to biomass debris 3-8% quicklime and 2-5% kaolin are mixed evenly and extruded to obtain a regular-shaped biomass fuel substrate; the second step is the preparation of an aeration and combustion-supporting binder. According to the mass ratio of 2-5%, add sodium bicarbonate aeration agent, 3-6% add potassium chlorate combustion-supporting agent, stir and mix evenly to obtain aeration-combustion-supporting adhesive; the third step, biomass fuel substrate Surface treatment, roughen the surface of the biomass fuel substrate obtained in the first step, and then coat the aeration-combustion-supporting adhesive obtained in the second step on the surface of the biomass fuel substrate to be pressed to form an aeration-combusti...

Embodiment 2

[0031] A method for preparing aeration and combustion-supporting biomass briquettes, comprising the following steps: the first step, the preparation of a biomass fuel substrate, crushing and pre-drying cellulose-based biomass debris, and adding an amount equivalent to biomass debris 3-8% quicklime and 2-5% kaolin are mixed evenly and extruded to obtain a regular-shaped biomass fuel substrate; the second step is the preparation of an aeration and combustion-supporting binder. According to the mass ratio of 2-5%, add sodium bicarbonate aeration agent, 3-6% add potassium chlorate combustion-supporting agent, stir and mix evenly to obtain aeration-combustion-supporting adhesive; the third step, biomass fuel substrate Surface treatment, roughen the surface of the biomass fuel substrate obtained in the first step, and then coat the aeration-combustion-supporting adhesive obtained in the second step on the surface of the biomass fuel substrate to be pressed to form an aeration-combust...

Embodiment 3

[0034] A method for preparing aeration and combustion-supporting biomass briquettes, comprising the following steps: the first step, the preparation of a biomass fuel substrate, crushing and pre-drying cellulose-based biomass debris, and adding an amount equivalent to biomass debris 3-8% quicklime and 2-5% kaolin are mixed evenly and extruded to obtain a regular-shaped biomass fuel substrate; the second step is the preparation of an aeration and combustion-supporting binder. According to the mass ratio of 2-5%, add sodium bicarbonate aeration agent, 3-6% add potassium chlorate combustion-supporting agent, stir and mix evenly to obtain aeration-combustion-supporting adhesive; the third step, biomass fuel substrate Surface treatment, roughen the surface of the biomass fuel substrate obtained in the first step, and then coat the aeration-combustion-supporting adhesive obtained in the second step on the surface of the biomass fuel substrate to be pressed to form an aeration-combust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com